Lexus GS300/400 (2000 year). Service manual - part 11

N20013

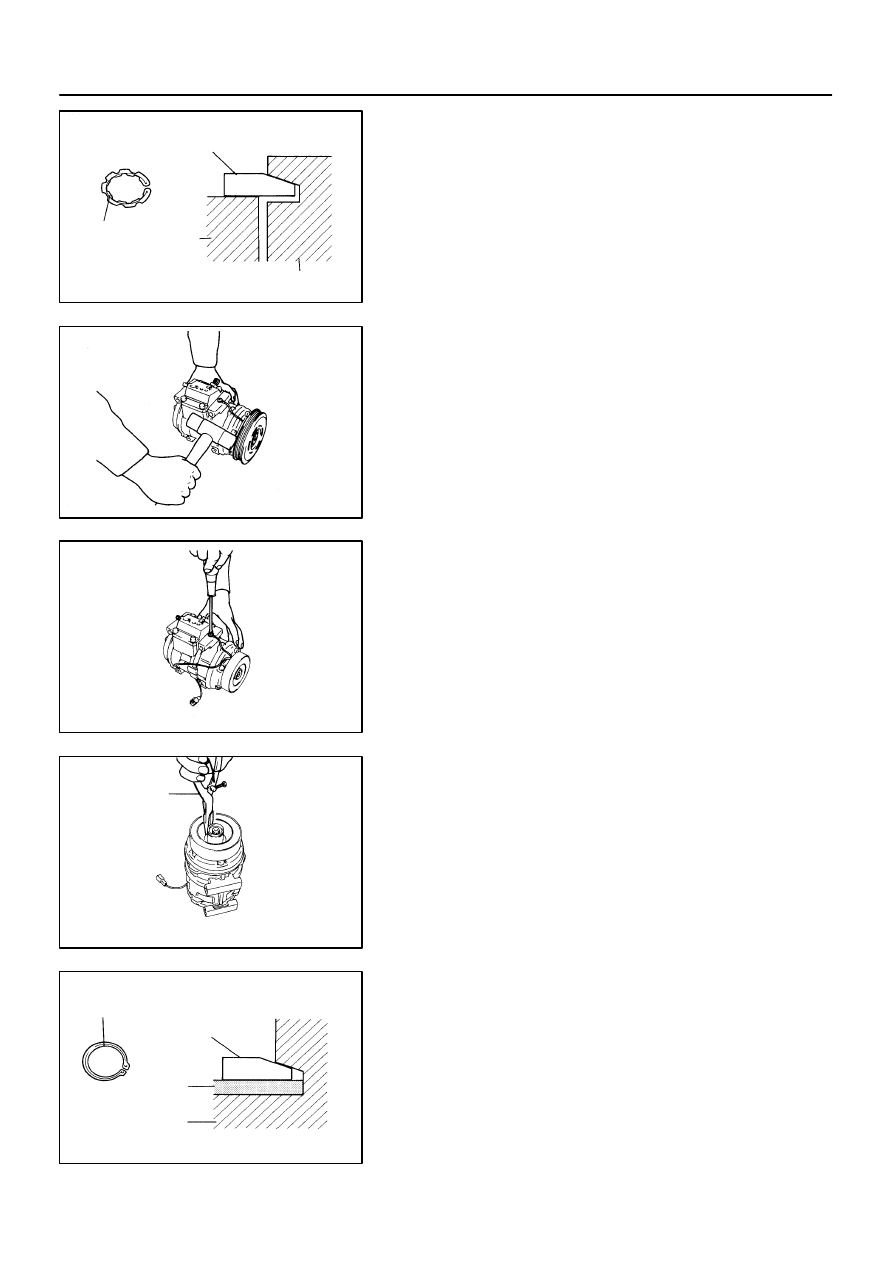

R–Shape

Rotor

Snap Ring

Compressor

AC1743

AC1744

AC0950

SST

N20012

R–Shape

Snap Ring

Compressor

Stator

–

AIR CONDITIONING

COMPRESSOR AND MAGNETIC CLUTCH

AC–41

2726

NOTICE:

At the time of reassembly, please refer to the following

item.

The snap ring should be installed so that beveled side

faces up.

(b)

Using a plastic hammer, tap the rotor off the shaft.

NOTICE:

Be careful not to damage the pulley when tapping on the ro-

tor.

3.

REMOVE STATOR

(a)

Disconnect the stator lead wire from the compressor

housing.

(b)

Using SST, remove the snap ring.

SST

07114–84020

NOTICE:

At the time of reassembly, please refer to the following

item.

The snap ring should be installed so that its beveled side

faces up.