Isuzu Trooper (1998-2002 year). Service manual - part 547

6G–15

ENGINE LUBRICATION

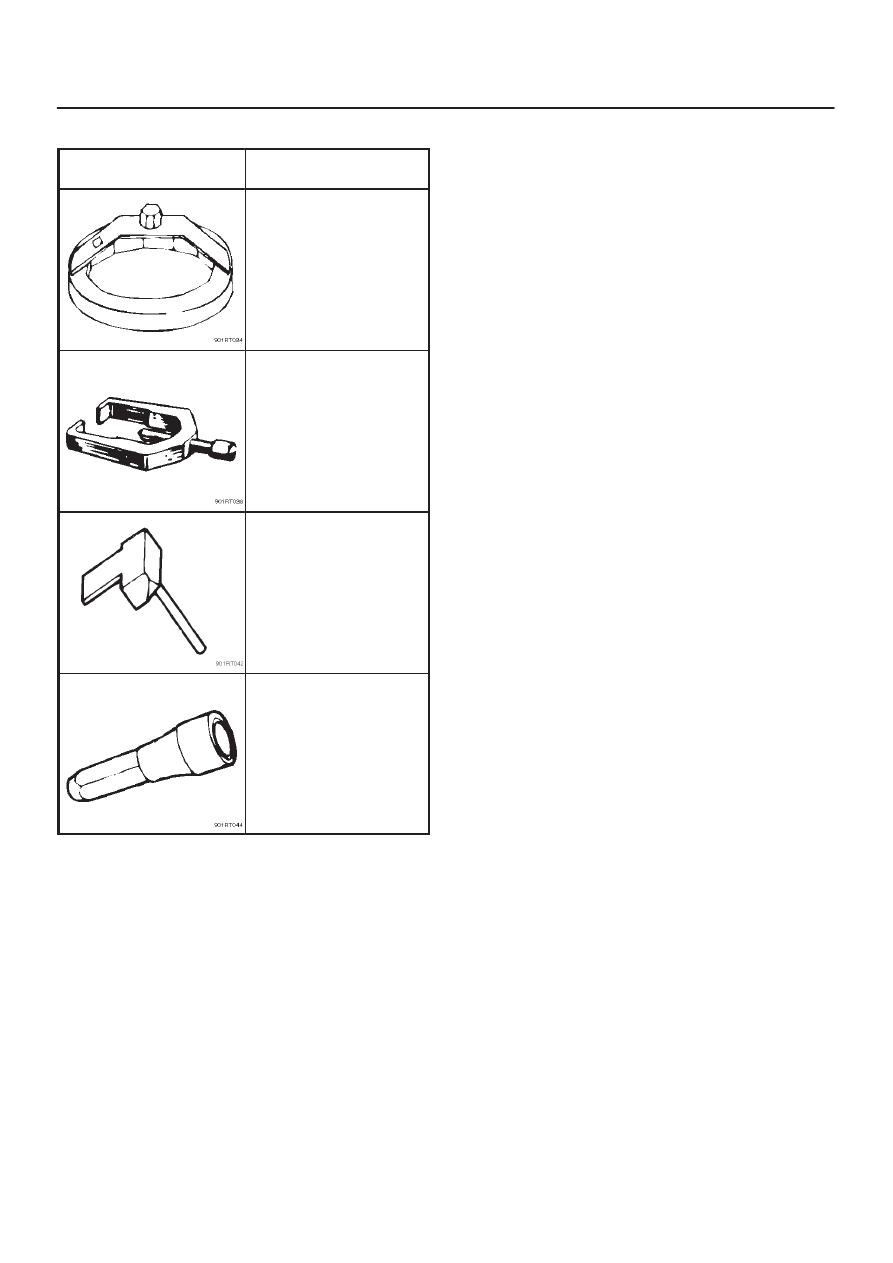

Special Tool

ILLUSTRATION

TOOL NO.

TOOL NAME

5–8840–0203–0

(J–36390)

Wrench; Oil filter

5–8840–2005–0

(J–29107)

Universal pitman arm

puller

5–8840–2153–0

(J–37228)

Seal cutter

5–8840–2287–0

(J–39202)

Installer; Oil pump oil

seal