Isuzu N-Series. Service manual - part 802

Engine Control System (4JH1) 6E-259

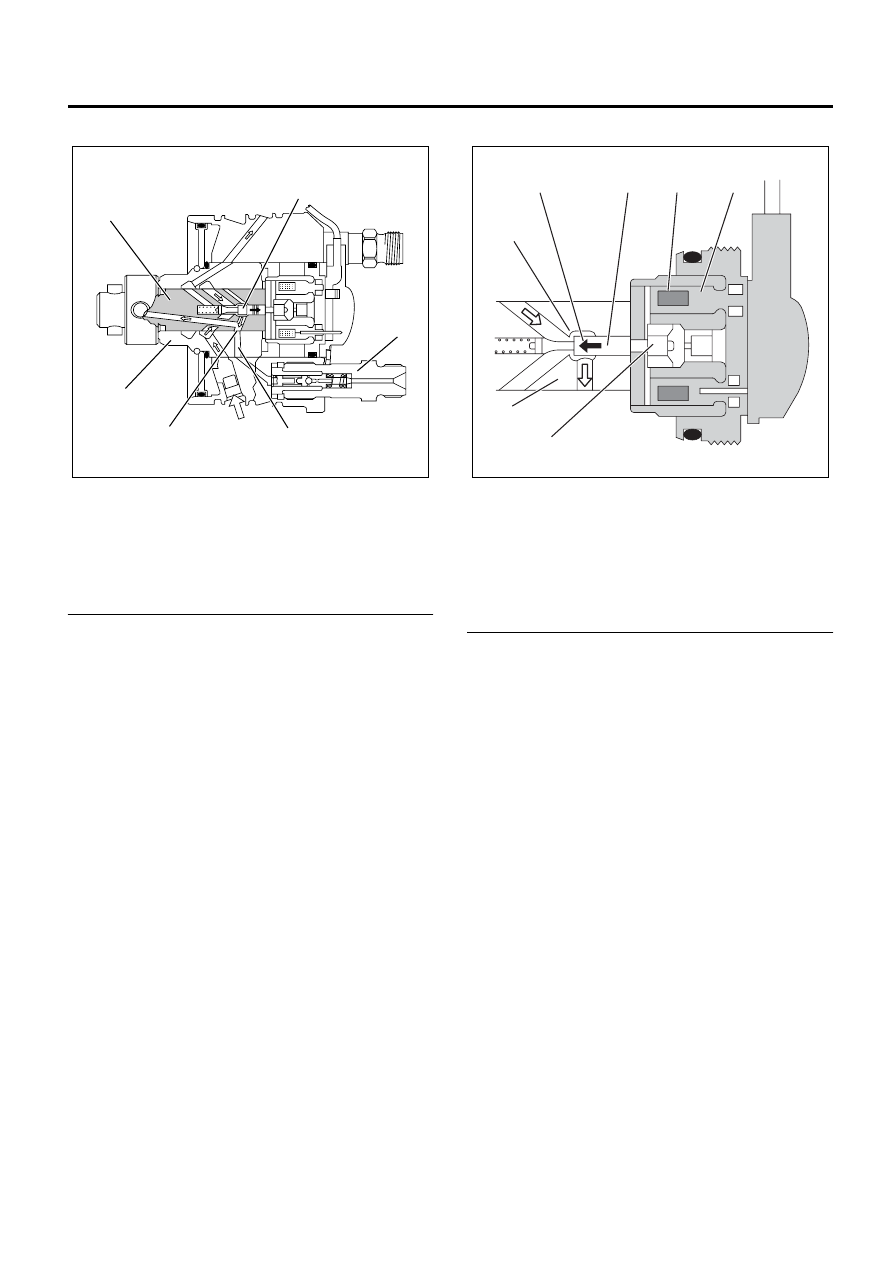

Distributor Head

Legend

1. Rotor Shaft

2. Valve Needle

3. Constant Pressure Valve (CPV) Holder

4. High Pressure Outlet

5. Distributor Shaft

6. Barrel

The distributor head distribute the high pressure fuel

that has flowed through the rotating rotor shaft’s

distributor slits and the barrel’s high pressure outlets (4

cylinders) to the engine cylinders via the constant

pressure valve (CPV) and the nozzle holder

assemblies. The fuel injection solenoid valve needle

changes the passage to the radial plunger high

pressure pump between fuel suction and fuel

compression.

Fuel Injection Solenoid Valve

Legend

1. Valve Seat

2. Valve Closing Direction

3. Valve Needle

4. Coil

5. Magnet

6. Magnet Anchor

7. Rotor Shaft

The fuel injection solenoid valve consists of a valve

seat, a valve needle, and a magnet anchor (a movable

iron core), a coil and a magnet. The valve needle

rotates together with the rotor shaft. When current

controlled by the fuel injection pump control unit (PCU)

flows to the coil, the magnet anchor and the valve

needle are pushed towards the valve seat. When the

valve seat is completely closed by the valve needle, the

fuel in the high pressure passage is isolated from the

low pressure passage, is compressed by the radial

plunger high pressure pump, and injected into the

engine cylinder through the nozzle holder assembly.

When the required injection quantity is reached, the

current to the coil is cut, the valve seat opens and

injection of fuel is completed.

1

2

3

4

5

6

N6A3848E

1

2

3

4

5

7

6

N6A3849E