Isuzu N-Series. Service manual - part 792

Engine Control System (4JH1) 6E-219

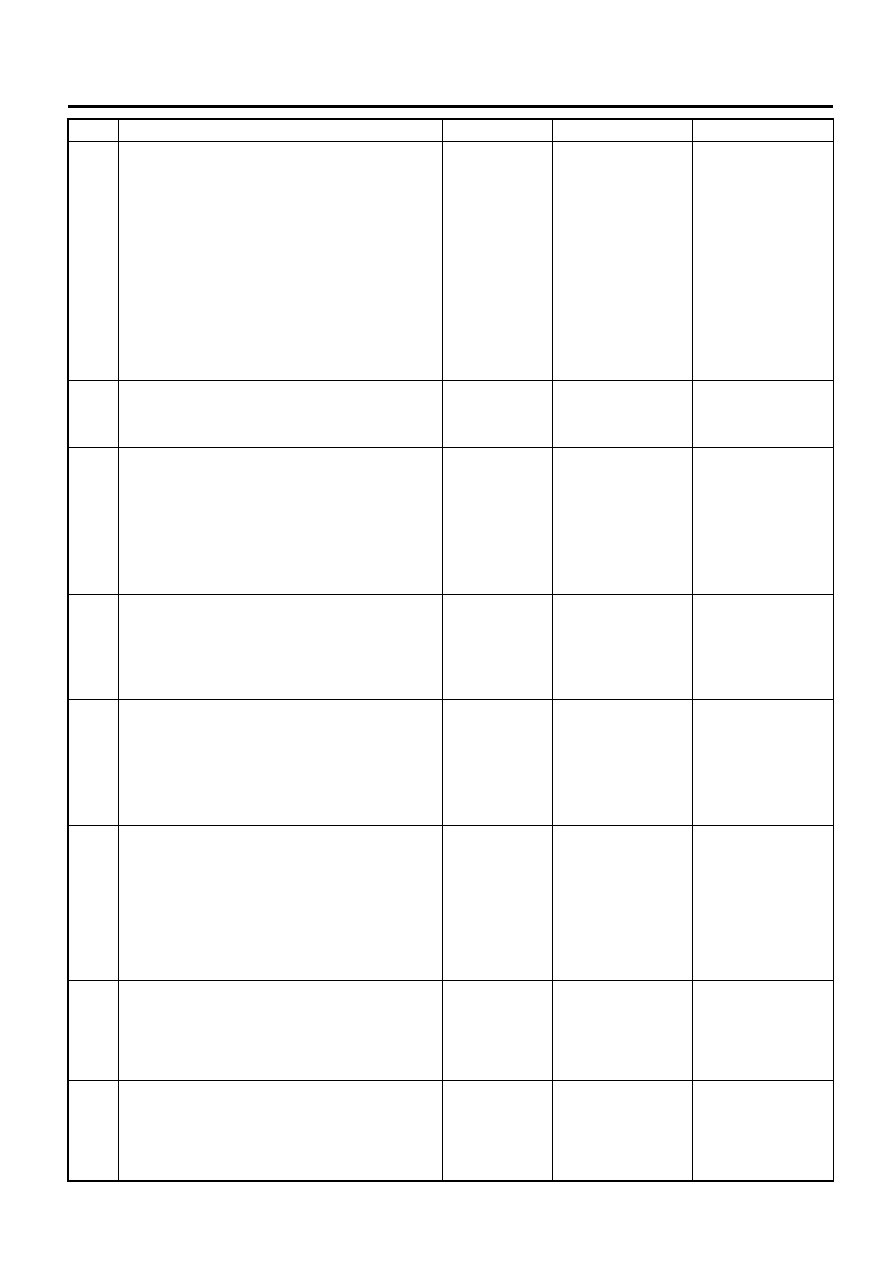

5

1.

Turn OFF the ignition.

2.

Replace the glow relay with the starter relay or

replace with a known good relay.

3.

Turn ON the ignition, with the engine OFF.

4.

Connect a test lamp between the metal bus

bar (glow plug power supply J-122 connector)

and a known good ground.

5.

Perform the Glow Relay test with the Tech 2.

6.

Command the Glow Relay ON with the Tech 2

while observing the test lamp.

Does the test lamp turn ON only when commanded

ON with the Tech 2?

—

Go to Step 9

Go to Step 6

6

Inspect the Glow (60A) slow blow fuse (SBF-3) in

the fuse & relay box.

Is the Glow (60A) slow blow fuse (SBF-3) open?

—

Go to Step 10

Go to Step 7

7

1.

Turn OFF the ignition.

2.

Remove the glow relay in the fuse & relay box.

3.

Connect a test lamp between the voltage feed

circuit of the glow relay terminal (pin 3 of X-20

connector) and a known good ground.

4.

Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

—

Go to Step 8

Go to Step 11

8

1.

Turn ON the ignition, with the engine OFF.

2.

Connect a test lamp between the power

supply circuit of glow plugs (pin 2 of X-20

connector) and a known good ground.

Does the test lamp illuminate?

—

Go to Step 13

Go to Step 12

9

1.

Turn OFF the ignition.

2.

Inspect for an intermittent and for poor

connections at the glow relay terminals (pins 2

and 3 of X-20 connector).

3.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 16

Go to Step 14

10

1.

Replace the Glow (60A) slow blow fuse (SBF-

3). If the slow blow fuse continues to open,

repair the short to ground on a circuit fed by

the slow blow fuse or check for a shorted

attached component.

2.

Repair the short to ground or replace the

component as necessary.

Did you complete the repair?

—

Go to Step 16

—

11

Repair the open circuit in the battery voltage supply

circuit between the Glow (60A) slow blow fuse

(SBF-3) and the glow relay (pin 3 of X-20

connector).

Did you complete the repair?

—

Go to Step 16

—

12

Repair the open circuit in the switched battery

voltage supply circuit between the glow relay (pin 2

of X-20 connector) and the glow plugs (J-122

terminal).

Did you complete the repair?

—

Go to Step 16

—

Step

Action

Value(s)

Yes

No