Isuzu N-Series. Service manual - part 726

6E-326 Engine Control System (4HK1)

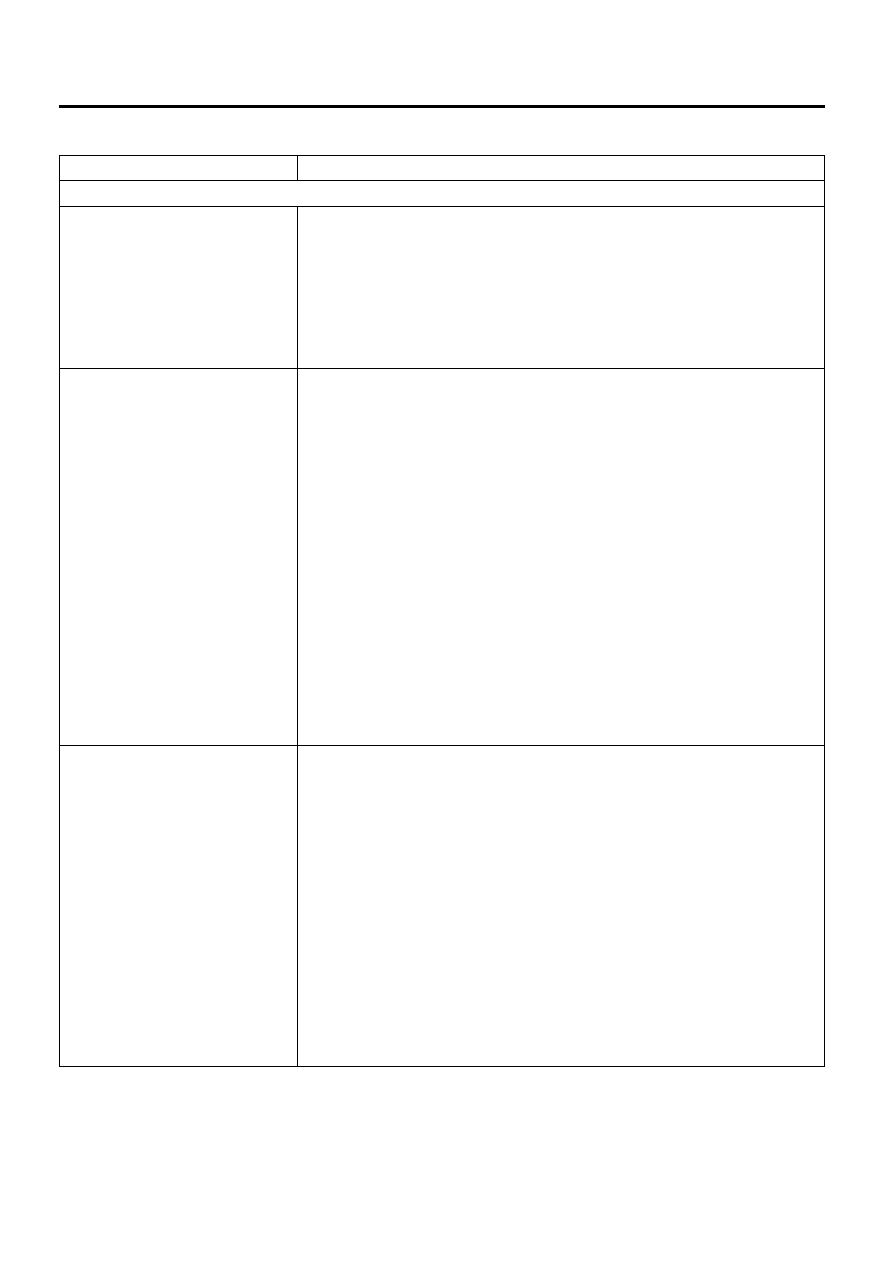

Excessive Smoke (Black Smoke)

Checks

Action

DEFINITION: Black smoke under load, idle or start up hot or cold.

Preliminary Check

• Ensure the vehicle has an actual problem.

• Inspect the engine control module (ECM) grounds for being clean, tight, and in their

proper locations.

• Remove the air cleaner and check for dirt, or for air ducts being plugged or

restricted. Replace as necessary.

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Inspect the programmed fuel injector ID code for each cylinder.

Sensor Checks

Inspect the engine control sensors for the following conditions. Refer to the Tech 2

Data List in this section.

• Use the Tech 2 to compare the Coolant Temperature with the Intake Air

Temperature (IAT) and Fuel Temperature (FT) on a cold engine condition. If the

difference among temperature reading is more than 5

°C (9°F) on a cold engine,

check for high resistance on the low reference circuit and signal circuit or for a

skewed sensor.

• Use the Tech 2 to observe the Fuel Rail Pressure (FRP) Sensor parameter with the

engine OFF. The FRP Sensor on the Tech 2 should read 0.9 – 1.0 volt with the key

ON and engine OFF after the engine has stopped running for a minimum of 2

minutes. If not, check for high resistance in the 5 volts reference circuit, low

reference circuit, signal circuits or for a skewed sensor.

• Use the Tech 2 to observe the Differential Fuel Rail Pressure parameter at idle and

W.O.T. (accelerator pedal full travel) in Neutral. Differential Fuel Rail Pressure

parameter should always be within

± 5 MPa (± 725 psi).

• Use the Tech 2 to observe the Boost Pressure and Barometric Pressure (BARO)

with ignition ON and engine OFF. Boost Pressure and BARO parameters should be

within the 1.0 psi (7.0 kPa) each other.

• Use the Tech 2 to observe the Accelerator Pedal Position (APP) Angle. APP Angle

parameter should change linearly from 0% to 100% according to the accelerator

pedal operation.

Fuel System Checks

Inspect the fuel system for the following conditions. Refer to the Fuel System section.

• Inspect the fuel supply pump operation.

Notice:

The fuel supply pump must be timed to the engine and adjustment value must be

learned to the ECM.

• Perform the Injector Balancing test with the Tech 2. Repair the wire or replace the

appropriate fuel injector that does not change engine speed when commanded

OFF.

• Perform the Injector Forced Drive test with the Tech 2. Repair the wire or replace

the appropriate fuel injector that does not create a clicking noise (solenoid

operating noise), contents an interrupted noise or has abnormal nose when

commanded ON.

• Use the Tech 2 to observe the Cylinder Compensation for each cylinder at idle. If

there is a cylinder that is excessively high or low value, it may indicate faulty fuel

injector, weak or slightly seized cylinder or an incorrectly programmed fuel injector

ID code.

• Inspect the fuel injectors. Remove the injectors and visually inspect.