Isuzu N-Series. Service manual - part 707

6E-250 Engine Control System (4HK1)

P1283 (Flash Code 24)

Circuit Description

The accelerator pedal position (APP) sensor is

mounted on the accelerator pedal control assembly.

The sensor is made up of two individual sensors within

one housing. The engine control module (ECM) uses

the APP sensors to determine the amount of

acceleration or deceleration desired by the person

driving the vehicle via the fuel injector control. The APP

sensor 2 has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• APP sensor 2 signal circuit

The ECM supplies 5 volts to the APP sensor 2 on the 5

volts reference circuit. The ECM also provides a ground

on the low reference circuit. The APP sensor 2

provides a signal to the ECM on the APP sensor 2

signal circuit, which is relative to the position changes

of the accelerator pedal angle. The ECM monitors the

APP sensor 2 signal for voltages outside the normal

range of the APP sensor 2. If the ECM detects an

excessively high APP sensor 2 signal voltage, this DTC

will set.

Condition for Running the DTC

• DTCs P1630 and P1632 are not set.

• The ignition switch is ON.

• The ignition voltage is more than 18 volts.

Condition for Setting the DTC

• The ECM detects that the APP sensor 2 signal

voltage is more than 4.9 volts.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs and fails.

• The ECM blinks the exhaust brake indicator lamp

when the diagnostic runs and fails.

• The ECM inhibits exhaust brake control.

Condition for Clearing the MIL / DTC

• The ECM turns OFF the MIL and exhaust brake

indicator lamp when the key is cycled after a

current DTC clears.

• A current DTC clears when the diagnostic runs and

does not fail at next driving cycle.

• A history DTC clears after 20 consecutive driving

cycles without a fault. Or clear with the Tech 2 or

accelerator pedal operation.

Diagnostic Aid

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

• APP sensor 2 may have an intermittent open

somewhere in the pedal range.

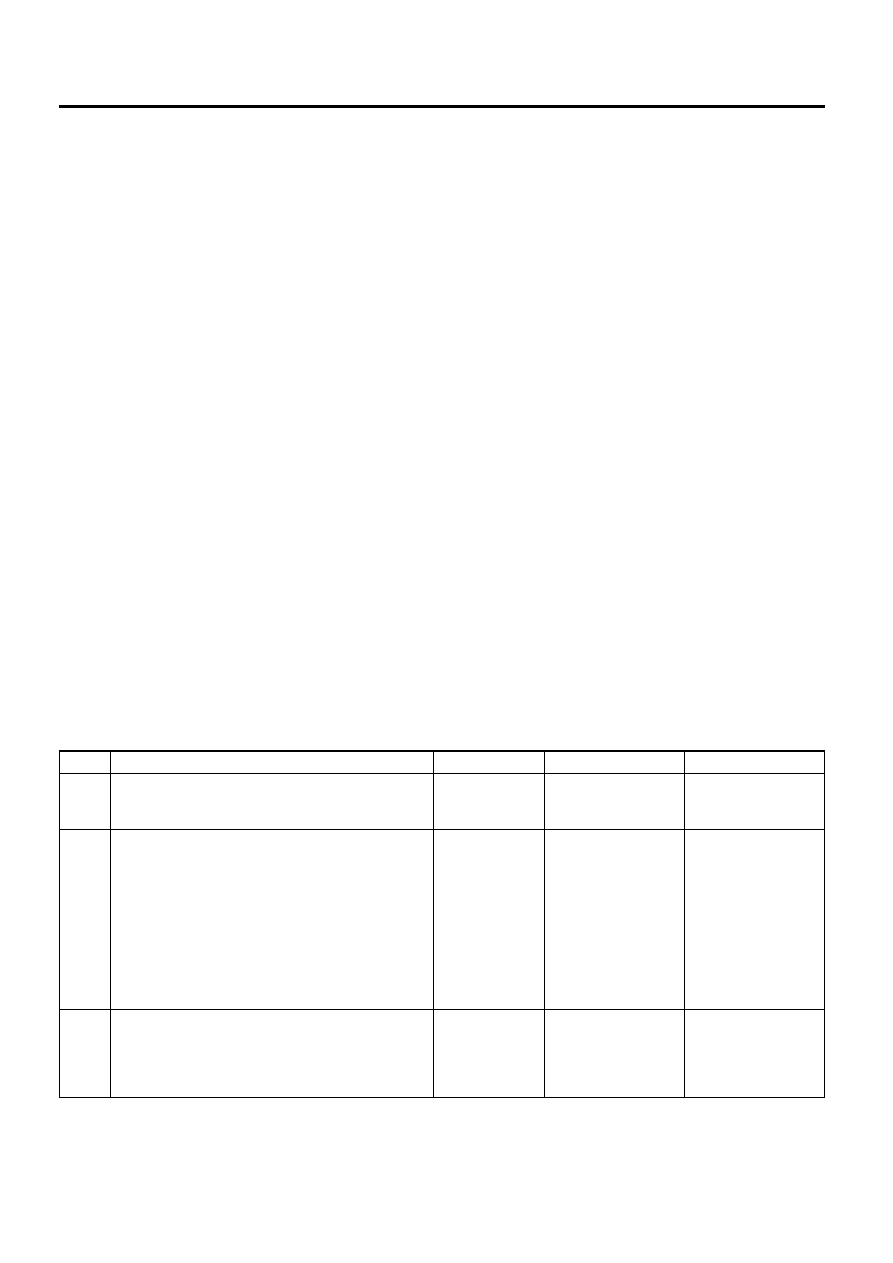

DTC P1283 (Flash Code 24)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check –

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System Check –

Engine Controls

2

1.

Install the Tech 2.

2.

Turn OFF the ignition for 30 seconds.

3.

Start the engine.

4.

Fully depress and release the accelerator

pedal while observing the Accelerator Pedal

Position (APP) Sensor 2 parameter with the

Tech 2.

Does the APP Sensor 2 parameter ever exceed the

specified value?

4.8 volts

Go to Step 3

Go to Diagnostic

Aids

3

1.

Start the engine.

2.

Monitor the Diagnostic Trouble Code (DTC)

Information with the Tech 2.

Is the DTC P1632 also set?

—

Go to Step 4

Go to Step 5