Isuzu N-Series. Service manual - part 693

6E-194 Engine Control System (4HK1)

P0606 (Flash Code 51, 52)

Circuit Description

This diagnostic applies to internal microprocessor

integrity conditions within the engine control module

(ECM).

Condition for Running the DTC

• The ignition switch is ON.

• The battery voltage is more than 16 volts.

Condition for Setting the DTC

Either of following condition is met:

• The ECM detects a malfunction in its internal main

central processing unit (CPU). (Flash Code 51)

• The ECM detects a malfunction in its internal sub

CPU. (Flash Code 52)

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits accelerator control range.

Condition for Clearing the MIL / DTC

• The ECM turns OFF the MIL when the key is

cycled after a current DTC clears.

• A current DTC clears when the diagnostic runs and

does not fail.

• A history DTC clears after 20 consecutive driving

cycles without a fault. Or clear with the Tech 2 or

accelerator pedal operation.

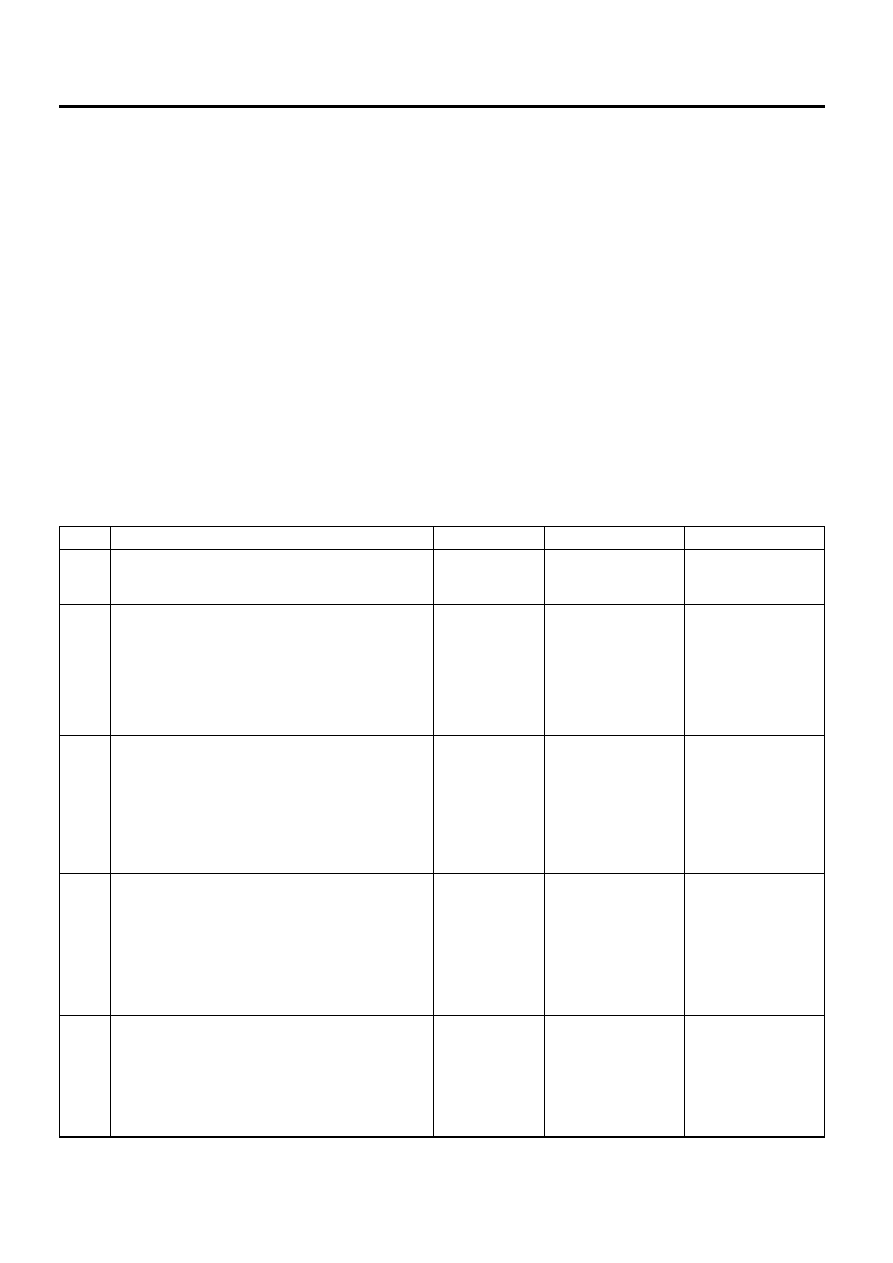

DTC P0606 (Flash Code 51, 52)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check –

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System Check –

Engine Controls

2

1.

Install the Tech 2.

2.

Turn OFF the ignition for 30 seconds.

3.

Start the engine.

4.

Monitor the Diagnostic Trouble Code (DTC)

Information with the Tech 2.

Does the DTC fail this ignition?

—

Go to Step 3

Go to Step 8

3

1.

Test each ground circuit between the engine

control module (ECM) (pins 1, 3, 4, 43, 62 and

81 of J-191 connector) and the chassis ground

terminal (J-9) for an open circuit or high

resistance.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 8

Go to Step 4

4

1.

Turn OFF the ignition.

2.

Inspect for an intermittent, for poor tightening

and corrosion at the chassis ground terminal

(J-9).

3.

Repair the tightening or clean the corrosion as

necessary.

Did you find and correct the condition?

—

Go to Step 8

Go to Step 5

5

1.

Test each ECM main relay voltage feed circuit

between the ECM (pins 2 and 5 of J-191

connector) and the ECM main relay (pin 2 of

X-18 connector) for high resistance.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 8

Go to Step 6