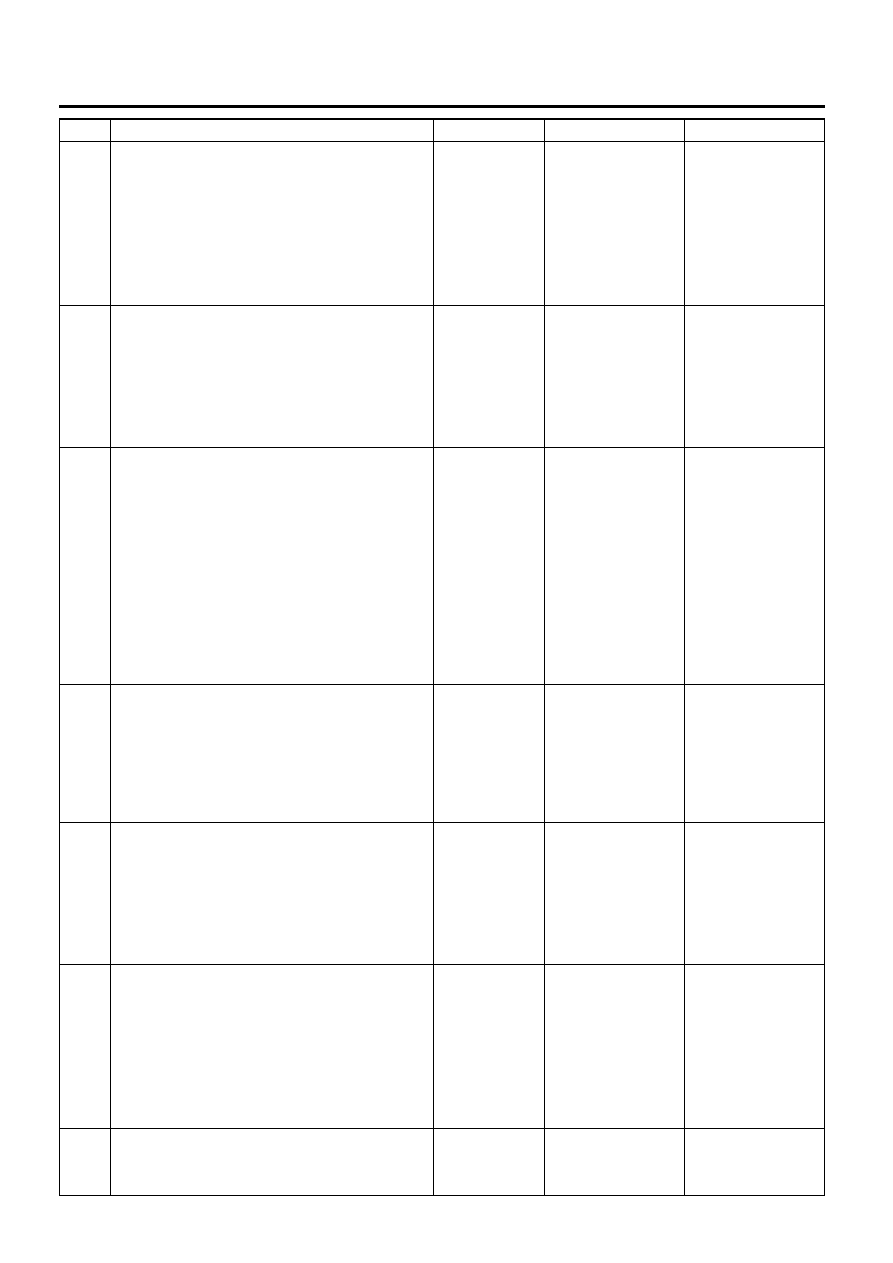

Isuzu N-Series. Service manual - part 684

6E-158 Engine Control System (4HK1)

5

1.

Turn OFF the ignition.

2.

Disconnect the boost pressure sensor

harness connector.

3.

Turn ON the ignition, with the engine OFF.

4.

Observe the Boost Pressure Sensor

parameter with the Tech 2.

Is the Boost Pressure Sensor parameter less than

the specified value?

0.1 volts

Go to Step 6

Go to Step 7

6

1.

Turn OFF the ignition.

2.

Connect a test lamp between the low

reference circuit of the boost pressure sensor

harness (pin 1 of J-216 connector) and battery

voltage.

3.

Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

—

Go to Step 9

Go to Step 8

7

Important:

The boost pressure sensor may be damaged if the

sensor signal circuit is shorted to a voltage source.

1.

Test the signal circuit between the engine

control module (ECM) (pin 91 of E-111

connector) and the boost pressure sensor (pin

2 of J-216 connector) for the following

conditions:

• A short to battery or ignition voltage

• A short to any 5 volts reference

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 13

Go to Step 12

8

1.

Test the low reference circuit between the

ECM (pin 109 of E-111 connector) and the

boost pressure sensor (pin 1 of J-216

connector) for an open circuit or high

resistance.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 13

Go to Step 10

9

1.

Turn OFF the ignition.

2.

Inspect for an intermittent and for a poor

connection at the harness connector of the

boost pressure sensor (pin 1 of J-216

connector).

3.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 13

Go to Step 11

10

1.

Turn OFF the ignition.

2.

Disconnect the ECM harness connector.

3.

Inspect for an intermittent and for a poor

connection on the boost pressure sensor

circuit at the harness connector of the ECM

(pin 109 of E-111 connector).

4.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 13

Go to Step 12

11

Replace the boost pressure sensor. Refer to Boost

Pressure Sensor Replacement in this section.

Did you complete the replacement?

—

Go to Step 13

—

Step

Action

Value(s)

Yes

No