Isuzu N-Series. Service manual - part 654

6E-38 Engine Control System (4HK1)

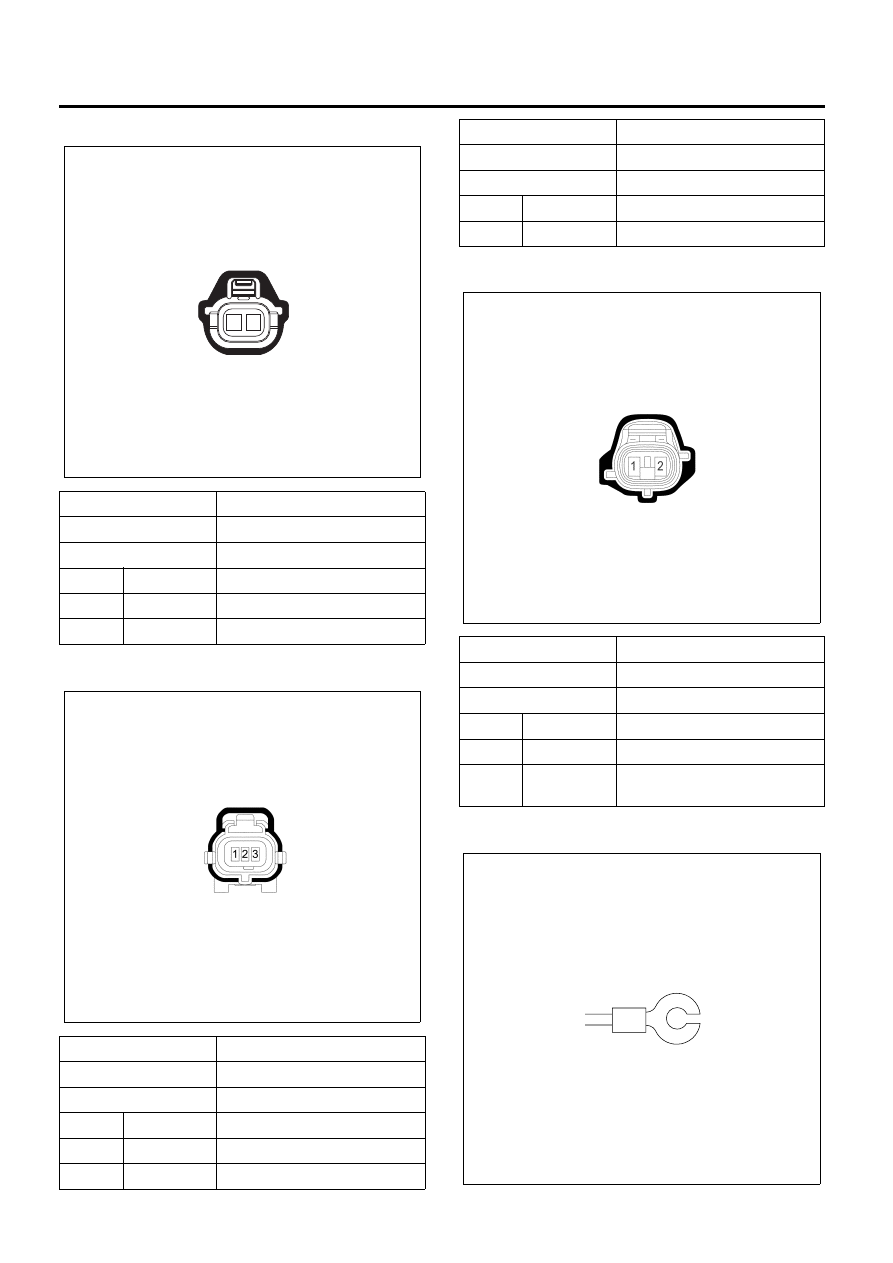

Fuel Rail Pressure (FRP) Regulator

Fuel Rail Pressure (FRP) Sensor

Fuel Temperature (FT) Sensor

Glow Plug

Connector No.

E-116

Connector Color

Gray

Test Adapter No.

J-35616-33

Pin

Wire Color

Pin Function

1

WHT/RED

FRP Regulator High Control

2

GRN/RED

FRP Regulator Low Control

Connector No.

E-113

Connector Color

Black

Test Adapter No.

J-35616-64A

Pin

Wire Color

Pin Function

1

BRN

FRP Sensor Low Reference

2

WHT

FRP Sensor Signal

1

2

N6A6455E

N6A6555E

3

GRN/BLU

FRP Sensor 5 Volts Reference

Connector No.

E-93

Connector Color

Green

Test Adapter No.

J-35616-64A

Pin

Wire Color

Pin Function

1

BLK

FT Sensor Low Reference

2

LT GRN/

WHT

FT Sensor Signal

Connector No.

E-113

Connector Color

Black

Test Adapter No.

J-35616-64A

Pin

Wire Color

Pin Function

N6A6556E

N6A3809E