Isuzu N-Series. Service manual - part 639

6E-4 EXHAUST GAS RECIRCULATION (EGR) SYSTEM

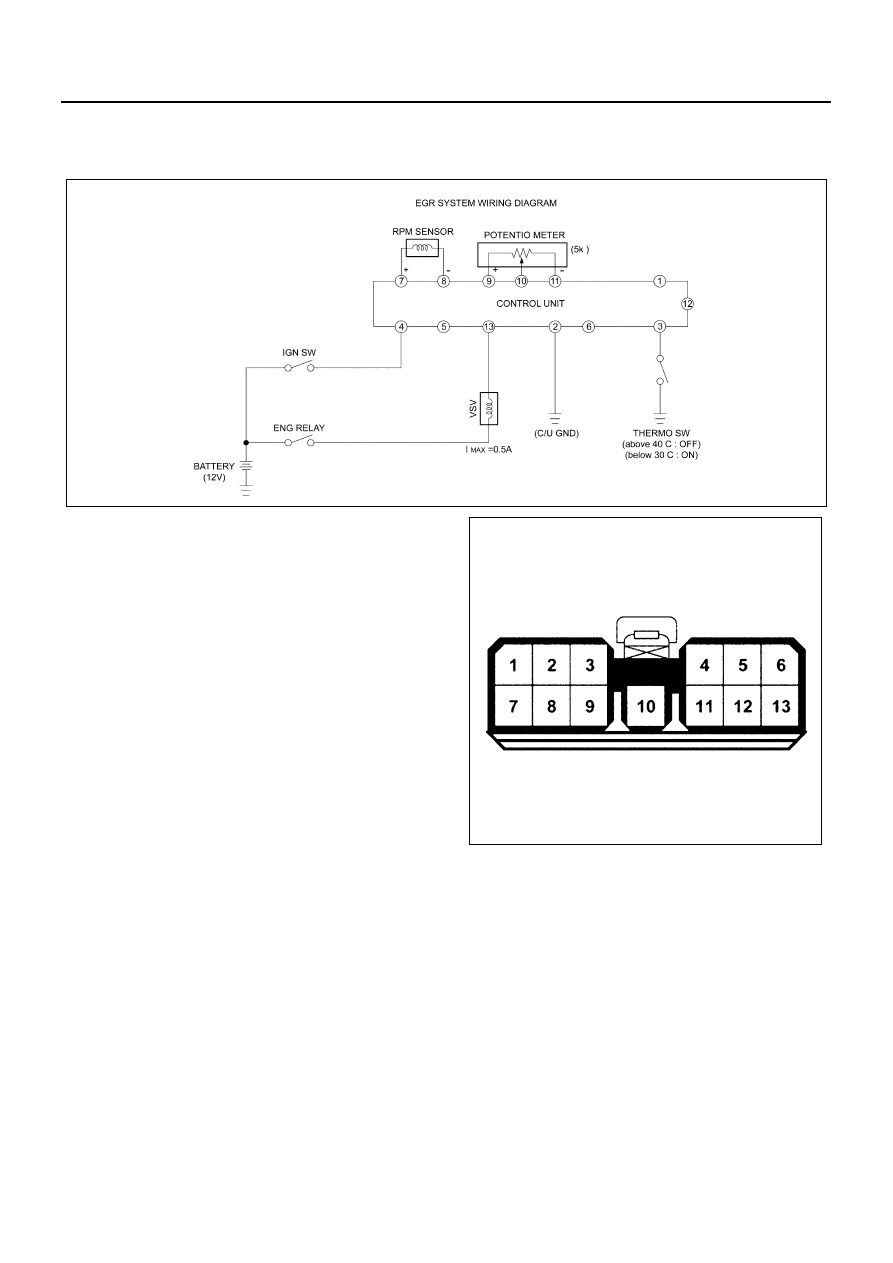

EGR SYSTEM WIRING DIAGRAM

For 4JB1-TC/4JG2

1. Connector Pin Assignment

N6A3580E

No.

Connector Name

1

—

2

Battery (

−) c/u GND

3

Thermo Switch

4

Battery (+)

5

—

6

—

7

rpm Signal (+)

8

rpm Signal (

−)

9

Potentiometer (+)

10

Potentiometer

11

Potentiometer (

−)

12

—

13

VSV

N6A3581E