Isuzu N-Series. Service manual - part 616

6C-34 ENGINE FUEL

Removal

Preparation:

• Disconnect battery ground cable.

• Drain coolant.

1. Cooling Fan Assembly

• Remove clamp nut, and remove cooling fan as-

sembly, distant pipe, and fan pulley.

2. Fan Shroud

3. Power Steering Pump Drive Belt (P/S Model)

• Loosen power steering pump mounting bolt and

adjust bolt, and remove the drive belt.

4. A/C Compressor Drive Belt (A/C Model)

• Loosen A/C compressor idler pulley lock nut, ad-

just bolt and remove the drive belt.

5. AC Generator Drive Belt

• Loosen AC generator mounting bolt (under side)

and adjust plate lock bolt, and remove the drive

belt.

6. Noise Shield Cover

7. Noise Cover Spacer

8. Air Intake Duct

9. Injection Pump Control Cable

• Remove the control cable bracket bolt and remove

the control lever side.

10. Fuel Hose

• Disconnect the fuel feed hose and fuel return hose.

11. CSD (Cold Starting Device) Water Hose

• Disconnect the water hose from injection pump

side.

12. Injection Pump Harness

• Remove the tachometer sensor (with tachometer),

CSD solenoid, fuel cut solenoid.

13. Injection Pipe

• Release pipe clip.

• Remove the flare nut on the pump side.

• Remove the flare nut on the injection nozzle side,

and remove the injection pipe.

Caution:

• Be sure to plug the injection nozzle holder and de-

livery holder to prevent the entry of foreign matter.

14. Injection Pump Assembly

• Remove pump mounting nut.

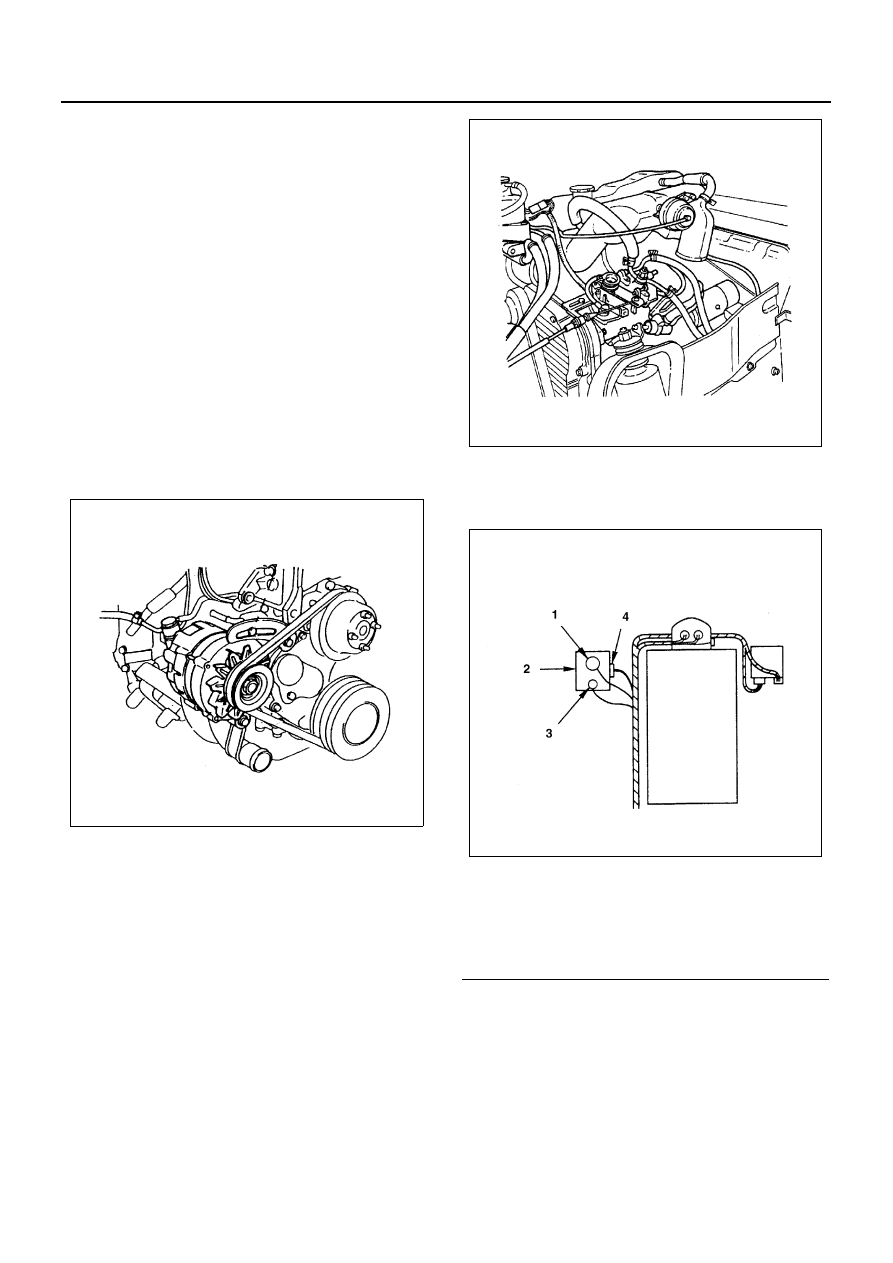

N6A3439E

Legend

1. CSD solenoid

2. Injection pump

3. Fuel cut solenoid

4. Tachometer sensor

N6A3440E

N6A3441E