Isuzu N-Series. Service manual - part 603

6A1-100 4JB1/4JB1-TC/4JG2/4JH1-TC - ENGINE

• A/C compressor pulley lock bolt loose, adjust belt

tension with adjuster’s adjust bolt.

Tighten:

• Idler lock nut to 27 N

⋅m (2.8 kg⋅m / 20 lb⋅ft)

8. Oil Pressure Switch Harness

• Connect the oil pressure switch harness connec-

tor.

9. Fuel Hose

• Connect the fuel feed hose and return hose then

tighten clip securely.

10. Glow Plug Harness

• Install the harness connector then tighten bolt se-

curely.

11. Engine Control Cable

1) Install the control wire to the engine control le-

ver.

2) Hold accelerator lever in the fully closed posi-

tion and stretch the control cable in the direc-

tion indicated by the arrow to remove any slack.

3) Tighten the accelerator cable bracket bolt.

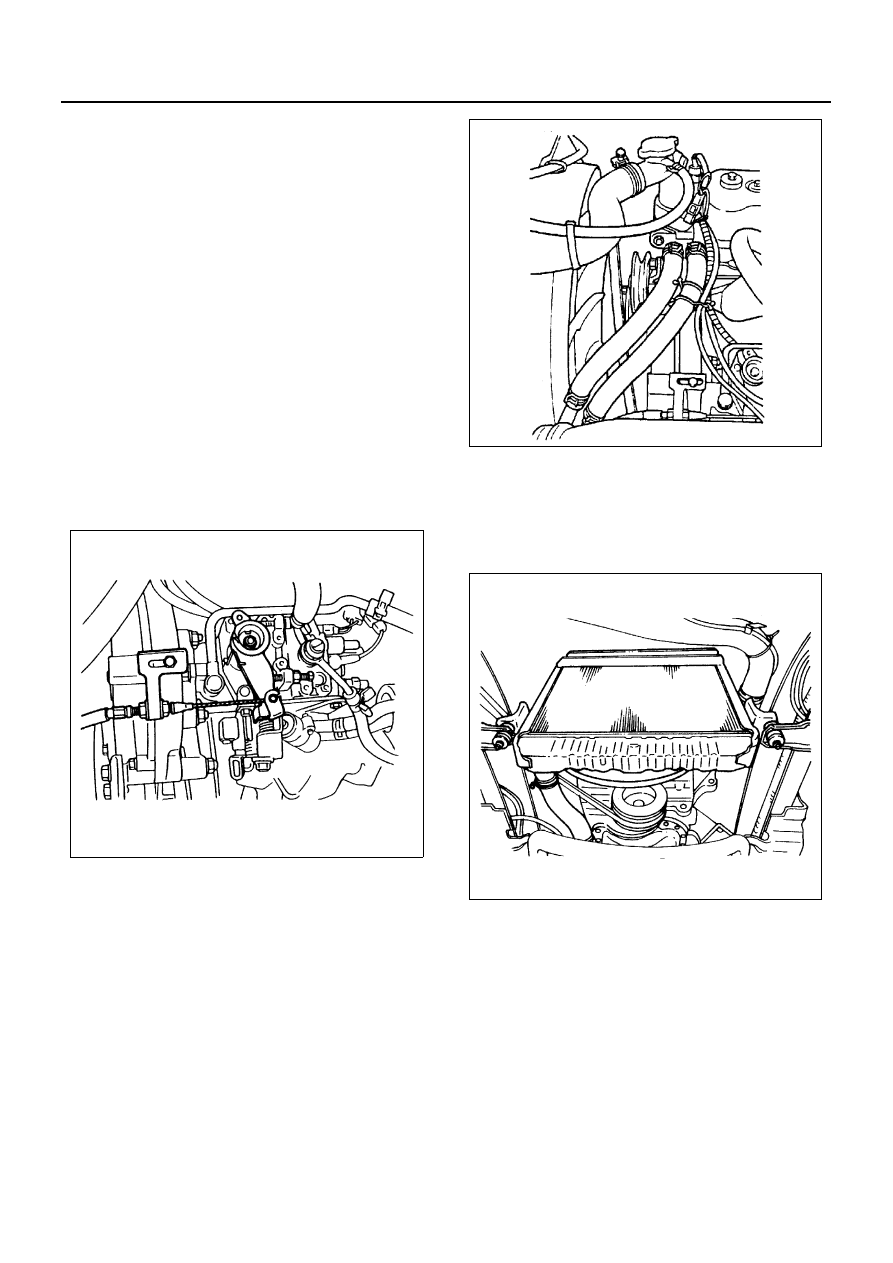

12. Heater Hose

• Connect the heater hose then tighten clip securely.

13. Intake Air Duct

• Connect the air duct then tighten clip securely.

14. Radiator Assembly

1) Install the cushion rubber on both sides.

2) Install the radiator stay

3) Connect the radiator hose upper and lower.

4) Connect the reservoir tank hose.

15. Transmission and Clutch Assembly

1) Driven Plate Assembly

• Apply multi-purpose with MOS2 type grease to

the driven plate hub spline.

• Use the pilot aligner to install the driven plate

assembly.

Pilot Aligner: 5-5825-3001-0

N6A3368E

N6A3360E

N6A3359E