Isuzu N-Series. Service manual - part 525

6C-8 Fuel System

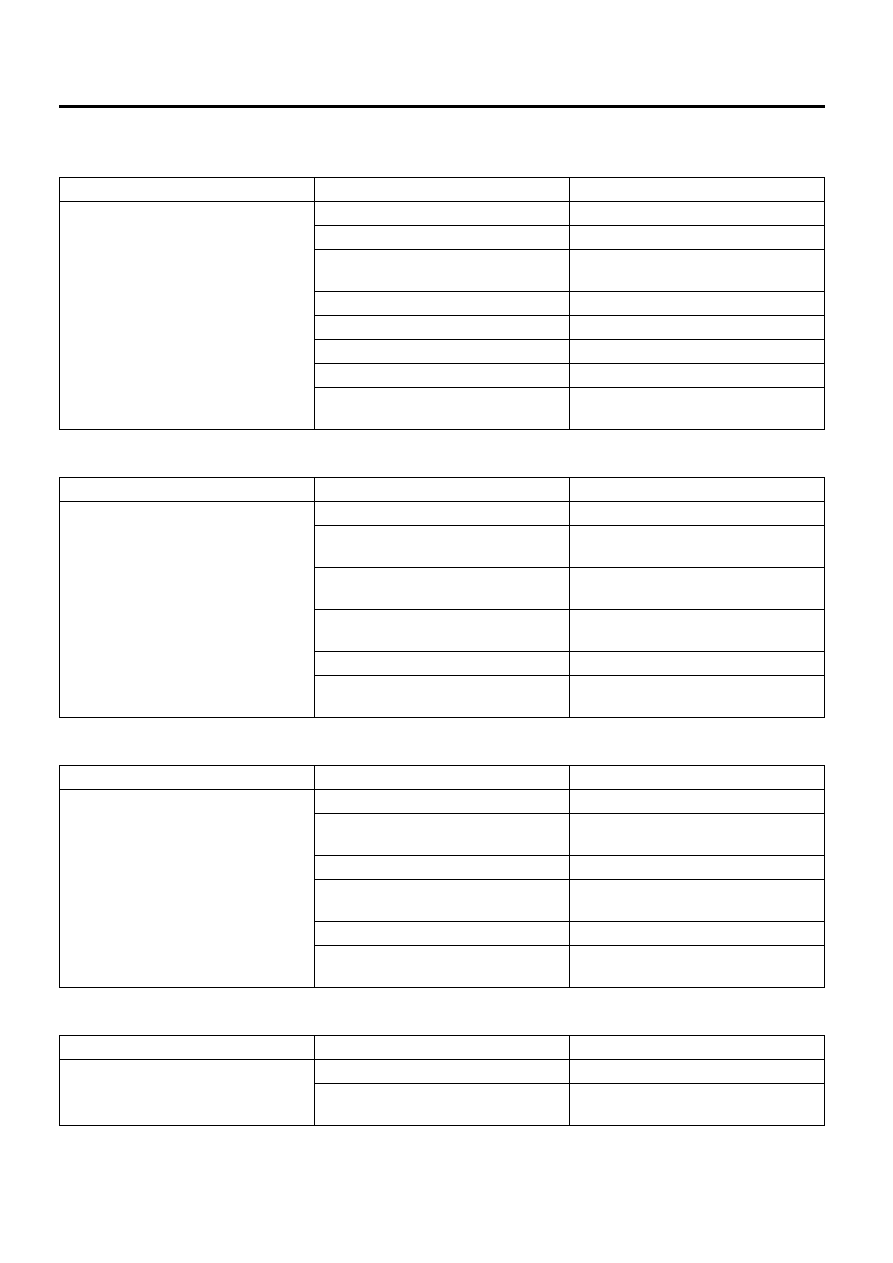

Trouble Shooting

Problems with starting

Unstable idling

Insufficient power

Maximum engine speed is too low

Condition

Possible Cause

Correction

Problems with starting

Fuel tank is empty

Fill the tank.

Air has entered the fuel system.

Bleed the air.

Fuel line is clogged or damaged.

Connection to the fuel line is loose.

Repair or replace the fuel line.

Re-tighten the connection.

Fuel filter element is clogged.

Replace the cartridge.

Fault in the feed pump

Replace the fuel supply pump.

Regulating valve is open.

Replace.

Sticking of the fuel injector nozzle

Replace the fuel injector.

Defective engine control system

Diagnose

the

engine

control

system.

Condition

Possible Cause

Correction

Hunting during idling

Air has entered the fuel system.

Bleed air from the fuel system.

Leakage or clogging of the fuel

system

Repair or replace the fuel system.

Water particles or foreign matter in

the fuel system.

Replace the fuel.

Fuel

filter

element

is

clogged.

Replace the fuel filter element

(cartridge).

Sticking of the fuel injector nozzle

Replace the fuel injector.

Defective engine control system

Diagnose

the

engine

control

system.

Condition

Possible Cause

Correction

Insufficient horsepower

Air has entered the fuel system.

Bleed air from the fuel system.

Leakage or clogging of the fuel

system

Repair or replace the fuel system.

Water mixes in the fuel system

Replace the fuel.

Fuel filter element is clogged.

Replace the element or the

cartridge.

Sticking of the fuel injector nozzle

Replace the fuel injector.

Defective engine control system

Diagnose

the

engine

control

system.

Condition

Possible Cause

Correction

Maximum engine speed is too low

Fuel line is clogged or damaged.

Repair or replace the fuel line.

Defective engine control system

Diagnose

the

engine

control

system.