Isuzu N-Series. Service manual - part 490

Engine Mechanical (4HK1-TC) 6A-65

Reassembly

1. Install the knock pin.

2. Install the camshaft gear.

• With the side of the camshaft gear center boss

part stuck out being on the camshaft side,

install the camshaft gear along with the knock

pin.

Tighten:

Bolt to 142 N

⋅m (14.5 kg⋅m/105 lb⋅ft)

Caution:

Be careful not to damage the cam and journal parts

when tightening up the gear.

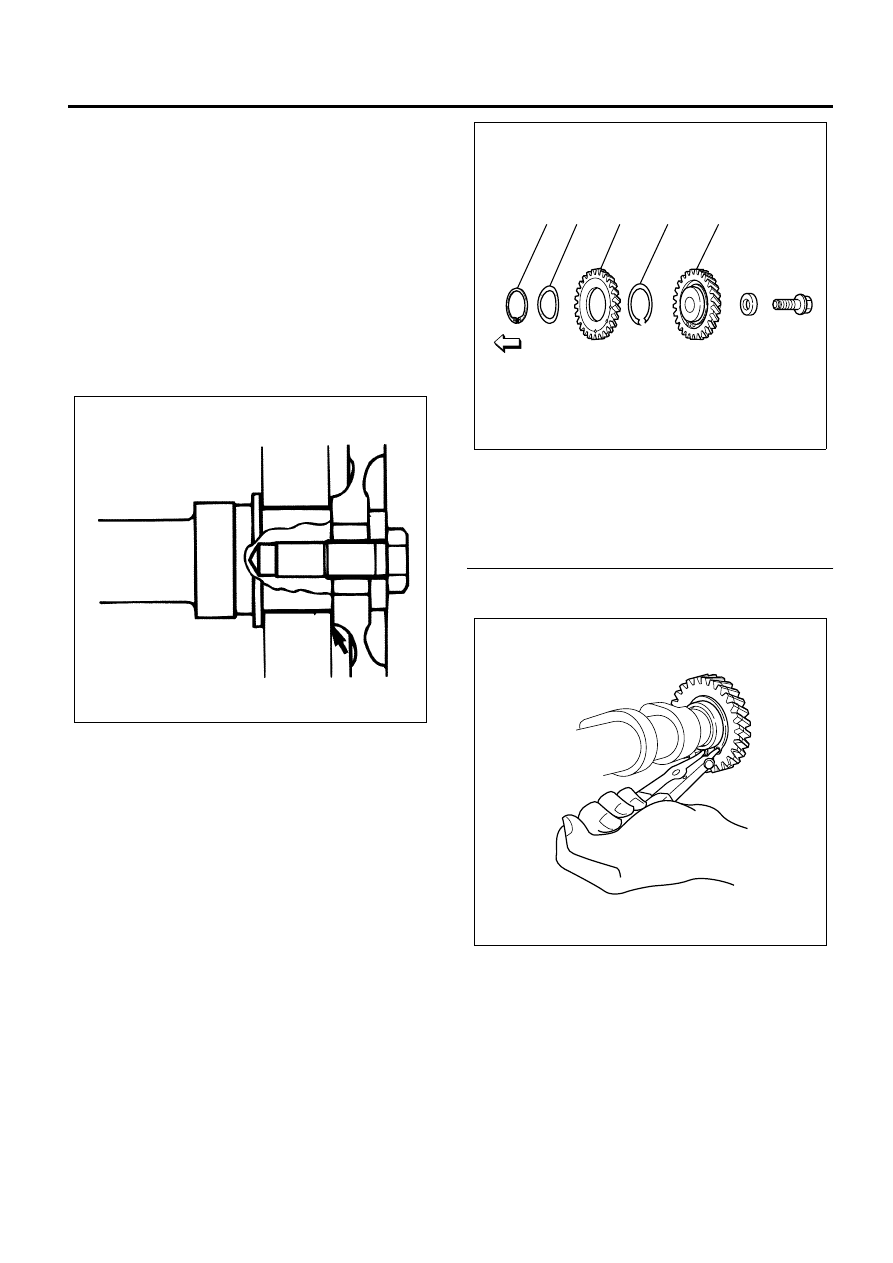

3. Install the scissors gear assembly.

• Fix the hexagon portion of the camshaft in a

vise using a mouth ring. Assemble the spring

with its left end contacting the pin of camshaft

main gear to make a gap on the right.

• Assemble the sub gear so that its pin is inserted

into the gap between the right side of pin of the

camshaft main gear and the right end of the

spring.

Legend

1. Snap Ring

2. Dish Washer

3. Sub Gear

4. Spring

5. Camshaft Gear

• Use snap ring pliers to assemble the snap ring

and the dish washer securely.

N6A6102E

1

2

3

4

5

N6A6099E

N6A6098E