Isuzu N-Series. Service manual - part 471

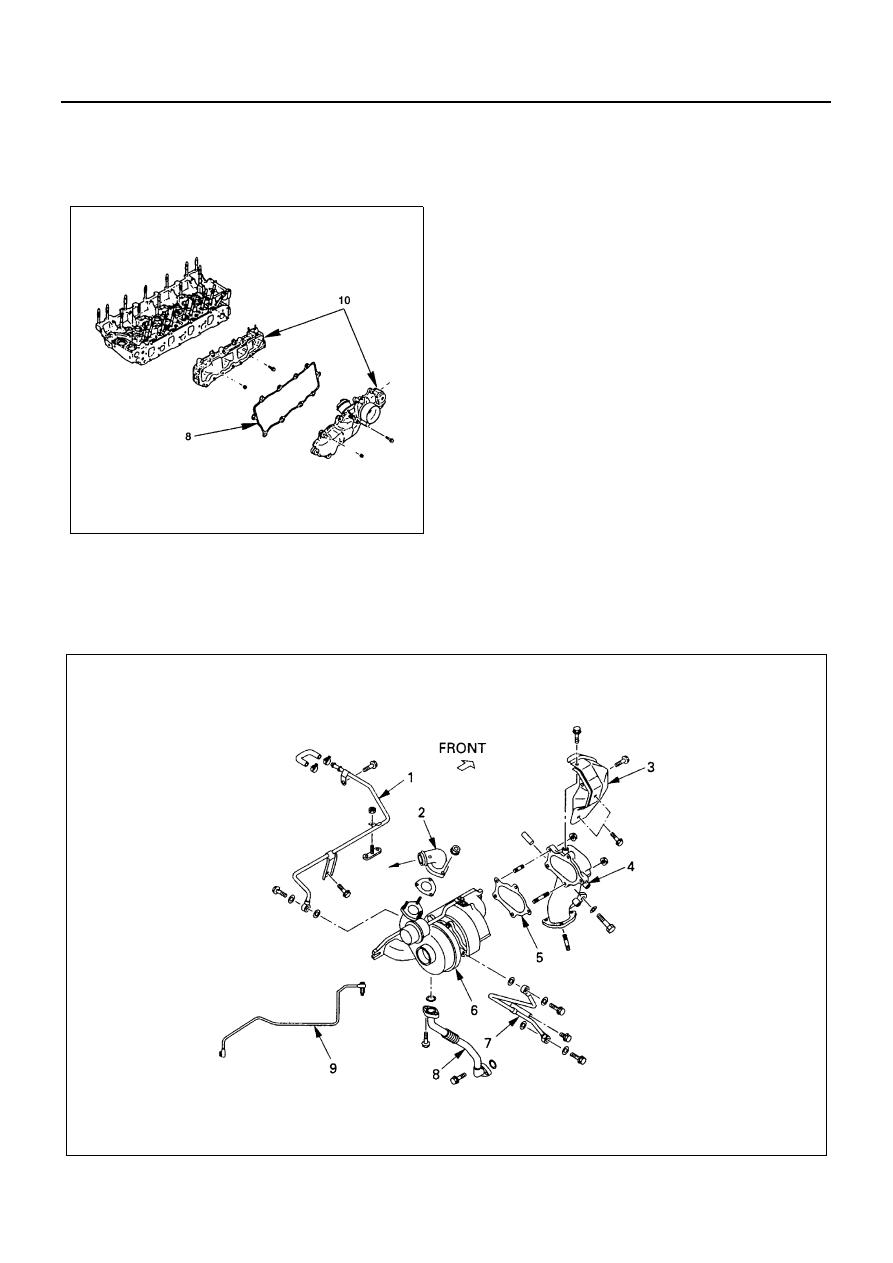

6G-4 TURBOCHARGER

8. Gasket.

9. Injection pipe.

10. Intake manifold.

11. Gasket and discard.

Installation

1. Intake manifold.

Tighten:

Intake manifold to 19 N

⋅m(1.9 kg⋅m/ 14 lb⋅ft)

2. Injection pipe

Tighten:

Fuel injector line nuts to 26 N

⋅m(2.7 kg⋅m/ 20 lb⋅ft)

3. Gasket

4. Charge air pipe.

5. Engine harness connector.

6. Bracket engine stop cable and vacuum hose.

7. Bracket accelerator cable.

8. Connecting hose.

9. Accelerator cable injection pump side.

10. PCV hose.

Turbocharger

Refer to “Statement on Cleanliness and Care” previous-

ly in this section.

Component

N6A1375E

N6A1373E