Isuzu N-Series. Service manual - part 376

6A3-156 ENGINE (4HF1 / 4HF1-2 / 4HE1-TC / 4HG1 / 4HG1-T)

For 4HE1-TC

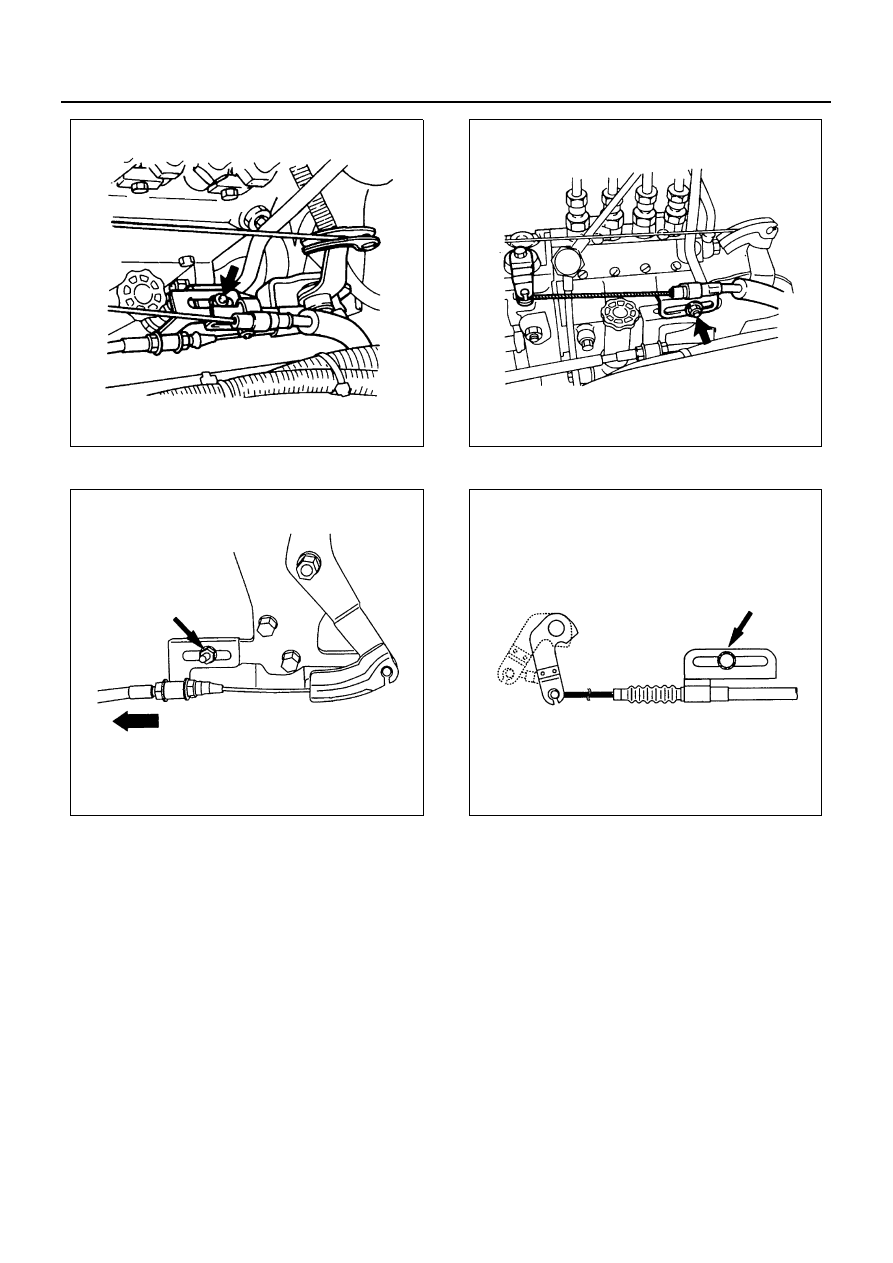

4) Check to see if the control lever of the injection

pump is at the idle position (with the lever in

touch with the stopper bolt).

4. Engine Stop Cable

1) Attach the end tip of the cable to the engine

stopper lever.

2) Pull the cable toward the rear side of the vehi-

cle, and fasten the clamp with a nut at the posi-

tion where the lever stops.

For 4HE1-TC

5. Vacuum Hose

6. Heater Hose

Install the hose with its mark (1) turned up.

N6A0526E

N6A0527E

N6A0525E

N6A0529E