Isuzu N-Series. Service manual - part 339

6A3-8 ENGINE (4HF1 / 4HF1-2 / 4HE1-TC / 4HG1 / 4HG1-T)

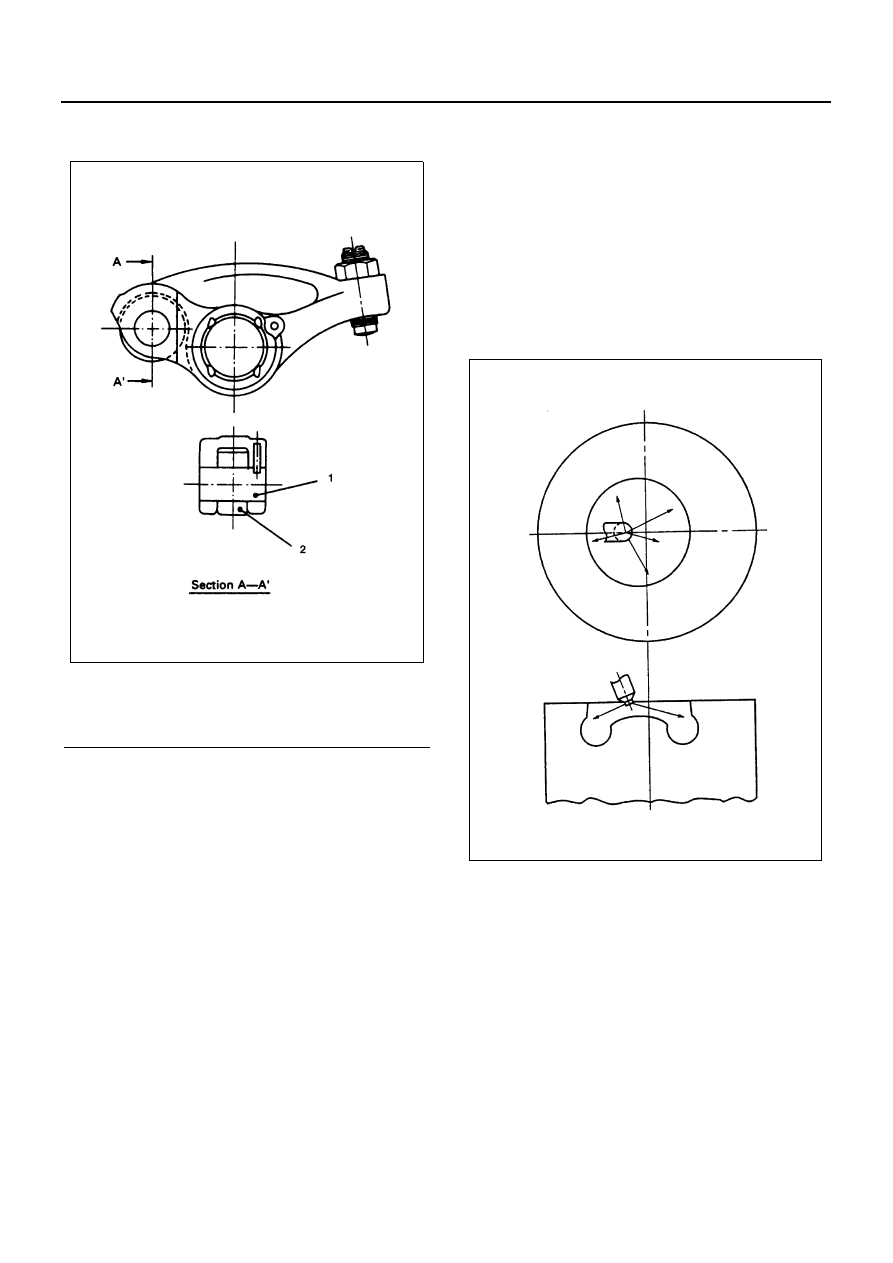

tributes to increased power output and fuel

efficiency (See figure).

• The rocker shaft is chrome plated to secure suffi-

cient durability.

Fuel System

LINE Pump

• The injection pump is of Bosch A type with the

plunger outside diameter of 9.5 mm (0.37 in) and

cam lift of 9 mm (0.35 in).

The plunger has a special notch for advancing the

timing at starting.

• The governor is of a mechanical RLD type to en-

sure sustained power at high speed.

• The timer is of the SCDM (eccentric) type.

VE Pump

• A Bosch Distributor Type injection Pump is used.

A single reciprocating / revolving plunger delivers

the fuel uniformly to the injection nozzles, regard-

less of the number of cylinders.

• The governor, the injection timer, and the feed

pump are all contained in the injection pump hous-

ing. The injection pump is compact, light weight,

and provides reliable high-speed operation.

An android compensator is available as an option

for vehicles to be operated at high altitudes. It ad-

justs the fuel and air mixing ratio.

Injection Nozzle

• The injection nozzle is of the P type to bring it as

technically close as possible to the center of the

combustion chamber. The nozzle inclination is also

reduced to minimum to increase combustion effi-

ciency.

The nozzle has five jets and the valve opening

pressure is set at 185 kg/cm

2

(2,630 psi, 18,142

kPa) (See figure).

• The injection pipe is laid in such a way that the

overall length is minimized to enhance perfor-

mance.

Intake and Exhaust Systems

• The resin-made intake manifold is of the cover type

having an inner cover made of rubber and steel.

This design effectively reduces radiant sound and

transmitted sound.

• The intake manifold has a straightening vane in-

side to stabilize swirl and improve performance. It

also contains a built-in Positive Crankcase Ventila-

tion (PCV) valve to minimize the overall size (See

figure).

• The exhaust manifold is mode of cast iron and he-

atresisting alloys. Ports are shaped carefully to

minimize exhaust resistance.

Legend

1. Pin

2. Roller

N6A0374E

N6A0375E