Isuzu N-Series. Service manual - part 336

6A-86 ENGINE MECHANICAL

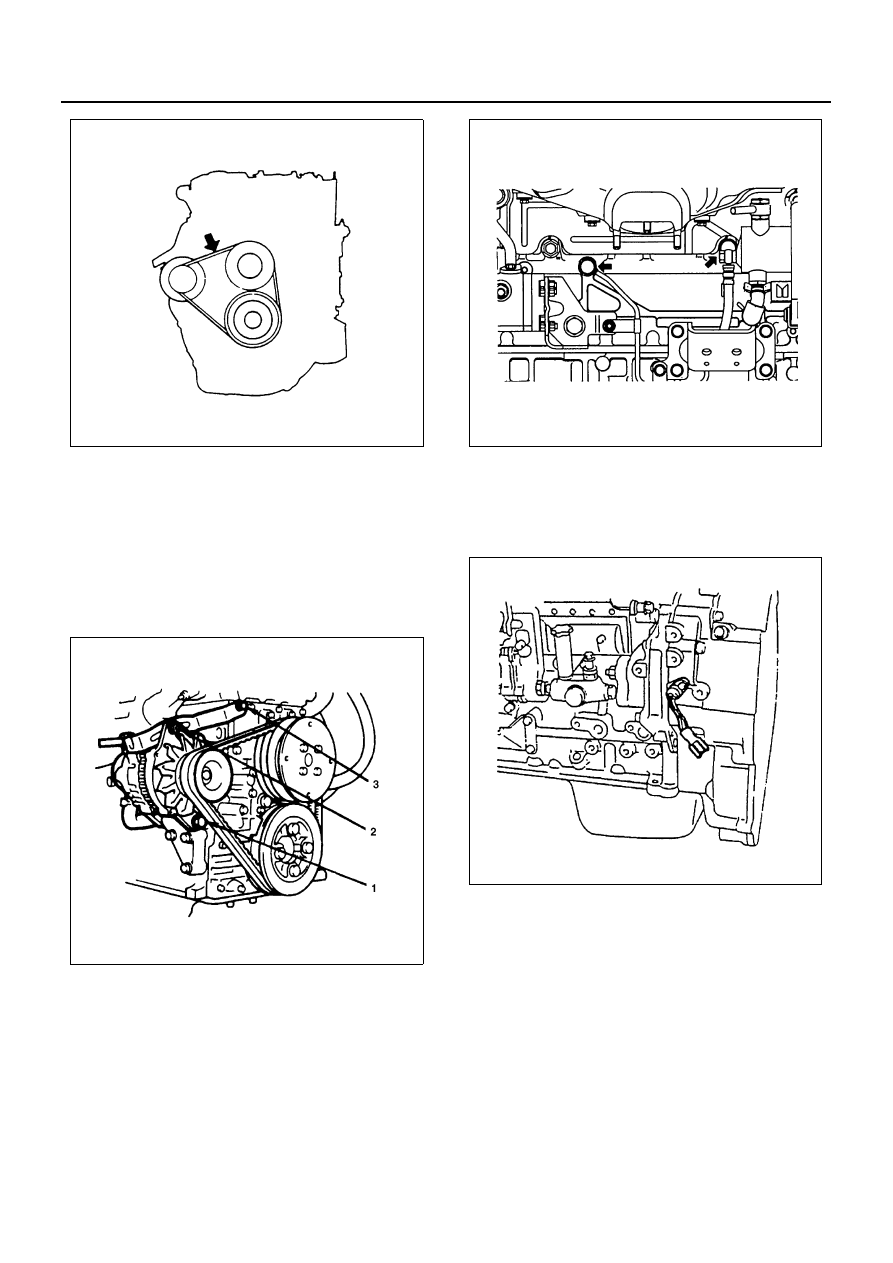

47. Fan Belt Adjustment

Fan belt tension is adjusted by moving the alterna-

tor.

Tighten:

Bolt to

• (1): 40 N

⋅m (4.1 kg⋅m / 30 lb⋅ft)

• (2): 24 N

⋅m (2.4 kg⋅m / 17 lb⋅ft)

• (3): 46 N

⋅m (4.7 kg⋅m / 34 lb⋅ft)

48. Vacuum Pump Rubber Hose

49. Vacuum Pump Oil Pipe

Tighten:

Cylinder body side pipe to 41 N

⋅m (4.2 kg⋅m / 30 lb⋅ft)

Tighten:

Generator side pipe to 23 N

⋅m (2.3 kg⋅m / 17 lb⋅ft)

50. Fuel Pipe Bracket

51. Tachometer Sensor

Tighten:

Tachometer bolt to 8 N

⋅m (0.8 kg⋅m / 6 lb⋅ft)

52. Oil Filter Assembly

Tighten:

Oil filter bolt to 48 N

⋅m (4.9 kg⋅m / 35 lb⋅ft)

53. Oil Pipe

Tighten:

Oil pipe joint bolt to 17 N

⋅m (1.7 kg⋅m / 12 lb⋅ft)

N6A0037E

N6A0038E

N6A0347E

N6A0348E