Isuzu N-Series. Service manual - part 215

HYDRAULIC BRAKES 5A-19

Notice:

Seal parts cannot be reused. When reassembling, be

sure to replace with a new seal kit.

1. Flexible hose

2. Pin bolt (Lock pin side)

3. Caliper assembly

• Slide the caliper assembly free from the inside.

4. Outer pad

5. Inner pad

6. Pad clips

7. Support assembly

• Remove the hub and disc before removing the

support assembly.

8. Wind guide

• Remove the hub and disc before removing the

wind guide.

9. Adapter

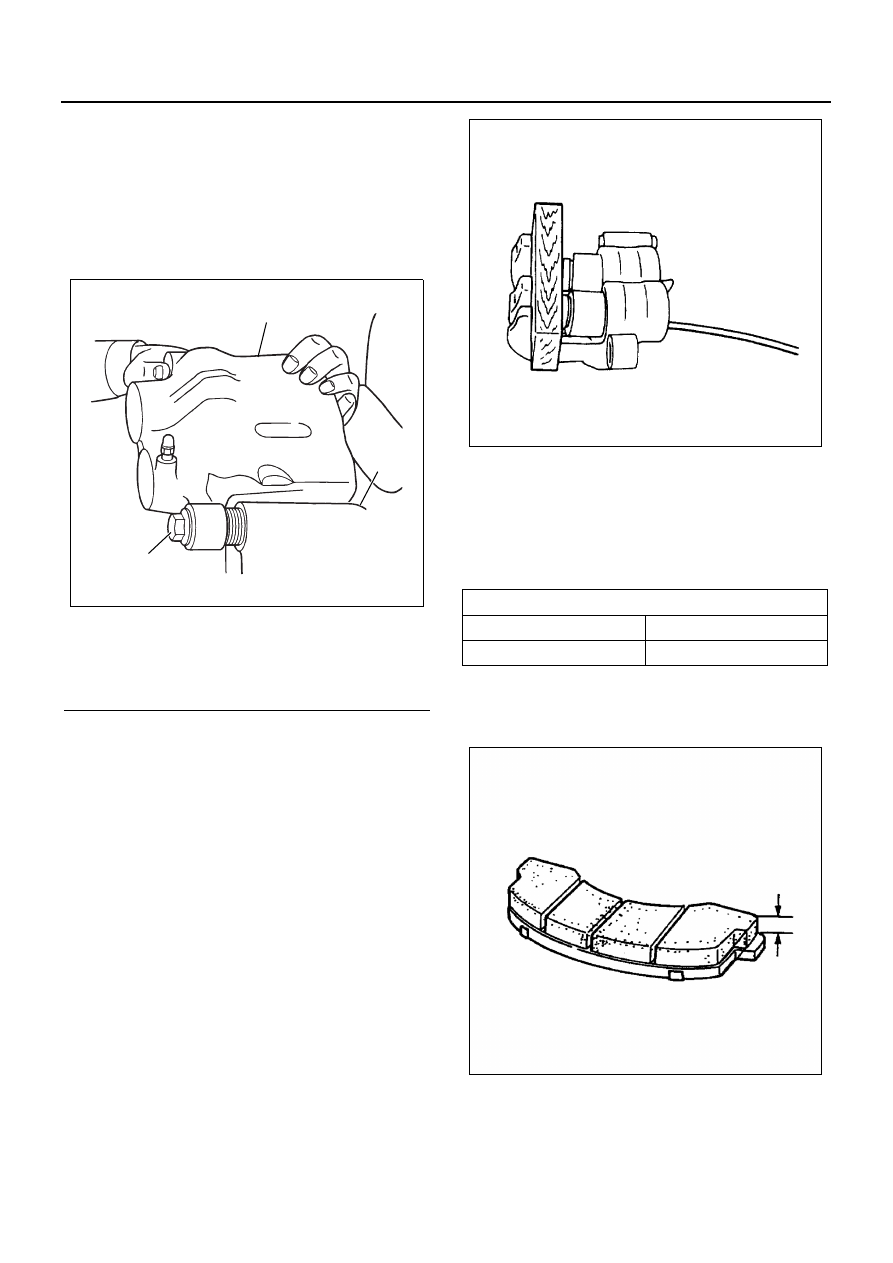

Disassembly

1. Place a piece of wood across the body assembly to

prevent piston damage.

2. Apply approximately 196 kPa (2.0 kg/cm

2

/ 28.4

psi) of compressed air to the body assembly oil

port to remove the pistons.

Inspection

1. All parts for wear distortion or other conditions and

replace as needed.

2. Inner and outer pads.

• Use a vernier caliper to measure the inner pad

and outer pad thickness.

• If the measured value is less than the specified

limit, the pads must be replaced with the repair

pad kit.

3. Piston and Cylinder Clearance.

• Use a micrometer to measure the piston diam-

eter.

• Use an inside dial indicator to measure the cyl-

inder bore.

Legend

1. Caliper Assembly

2. Support Assembly

3. Pin Bolt

3

1

2

N5A0432E

Pad Thickness

mm (in)

Standard

Limit

13 (0.51)

1 (0.04)

N5A0067E

N5A0093E