Content .. 1053 1054 1055 1056 ..

Isuzu N-Series. Service manual - part 1055

CAB AND CHASSIS ELECTRICAL 8-325

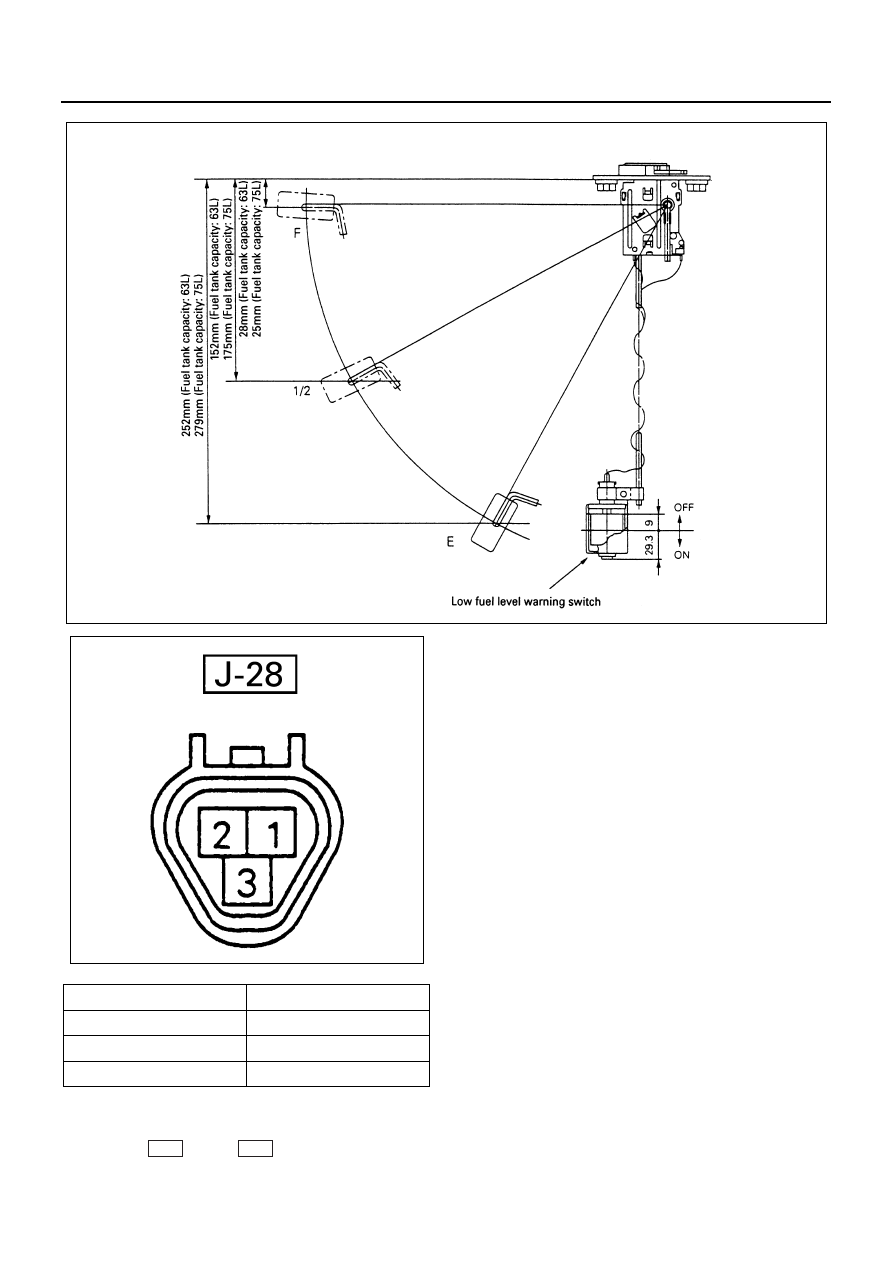

(Float type of warn low fuel level)

1. Check the resistance between the connector termi-

nals 1

and 3

while shifting the float

from “E” to “F” point.

2. Check if the low fuel warning light turns on when

the float is at “E” position. If found defective replace

the fuel tank unit.

N8A0352E

Float position

Resistance value (

Ω)

F

3

±2.1

1/2

32.5

±4.8

E

110

±7.7

N8A0331E

J-28

J-28