Isuzu N-Series. Service manual - part 14

POWER TAKE OFF 00-51

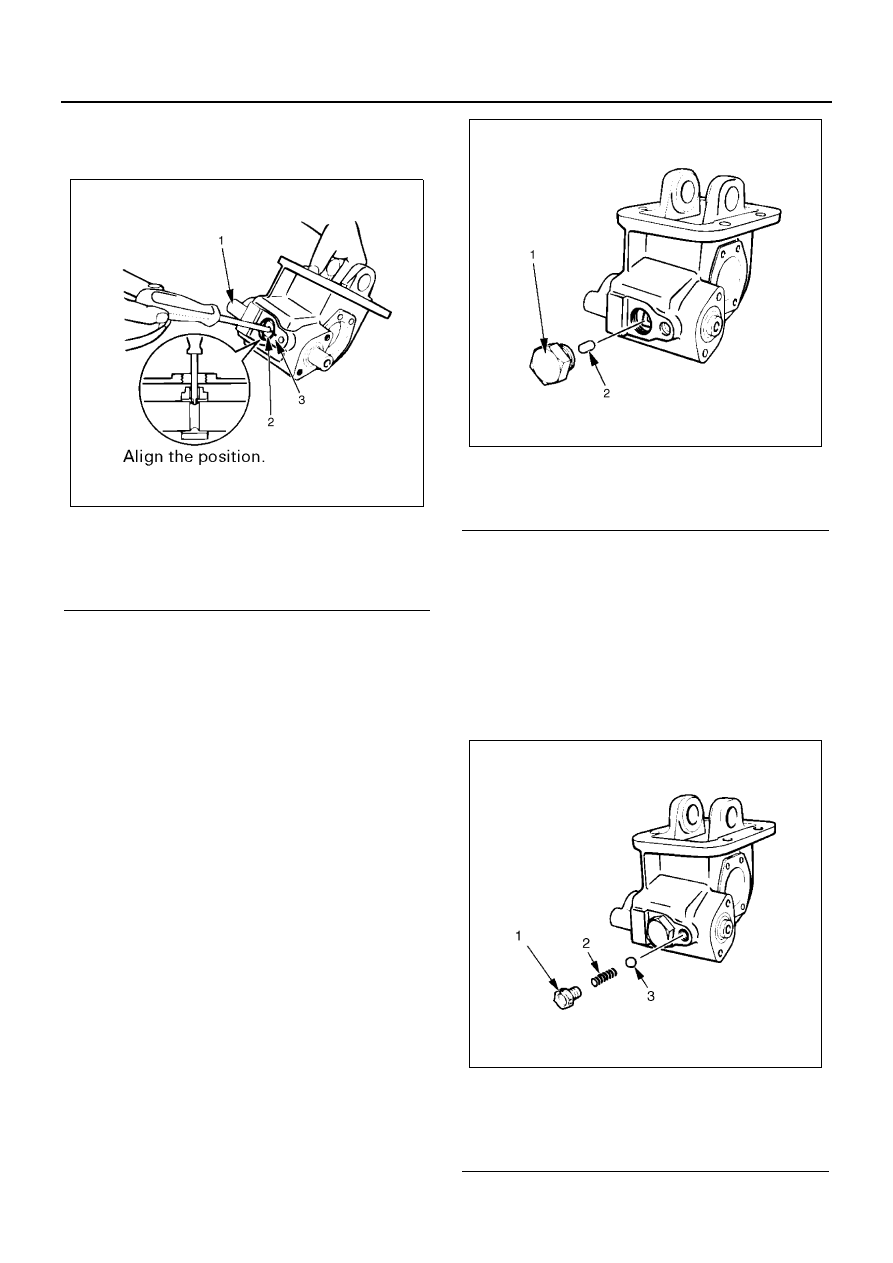

• Align the position between the lock pin hole of

the shift arm and the lock pin groove of the shift

rod.

7. Interlock Pin

8. Interlock Plug

• Assemble the interlock pin in the shift arm and

coat the interlock plug threaded portion with liq-

uid gasket (LOCTITE 242 or equivalent), then

tighten the interlock plug at a specified torque.

Tighten:

Interlock plug to 60 N

⋅m (6.1 kg⋅m / 44 lb⋅ft)

Notice:

After having tightened the interlock plug, do not move

the shift rod. Moving the shift rod may remove the inter-

lock pin.

9. Ball

10. Spring

11. Spring Set Bolt

• Assemble the ball and spring in the gear case

and coat the spring set bolt threaded portion

with liquid gasket (LOCTITE 242 or equivalent),

then tighten the spring set bolt.

Tighten:

Set bolt to 19 N

⋅m (1.9 kg⋅m / 14 lb⋅ft)

12. Output Gear

Legend

1. Shift rod

2. Shift arm

3. Alignment mark

NPA0123E

Legend

1. Interlock plug

2. Interlock pin

Legend

1. Spring set bolt

2. Spring

3. Ball

NPA0124E

NPA0125E