Isuzu Trooper (2000 year). Service manual - part 320

6E–409

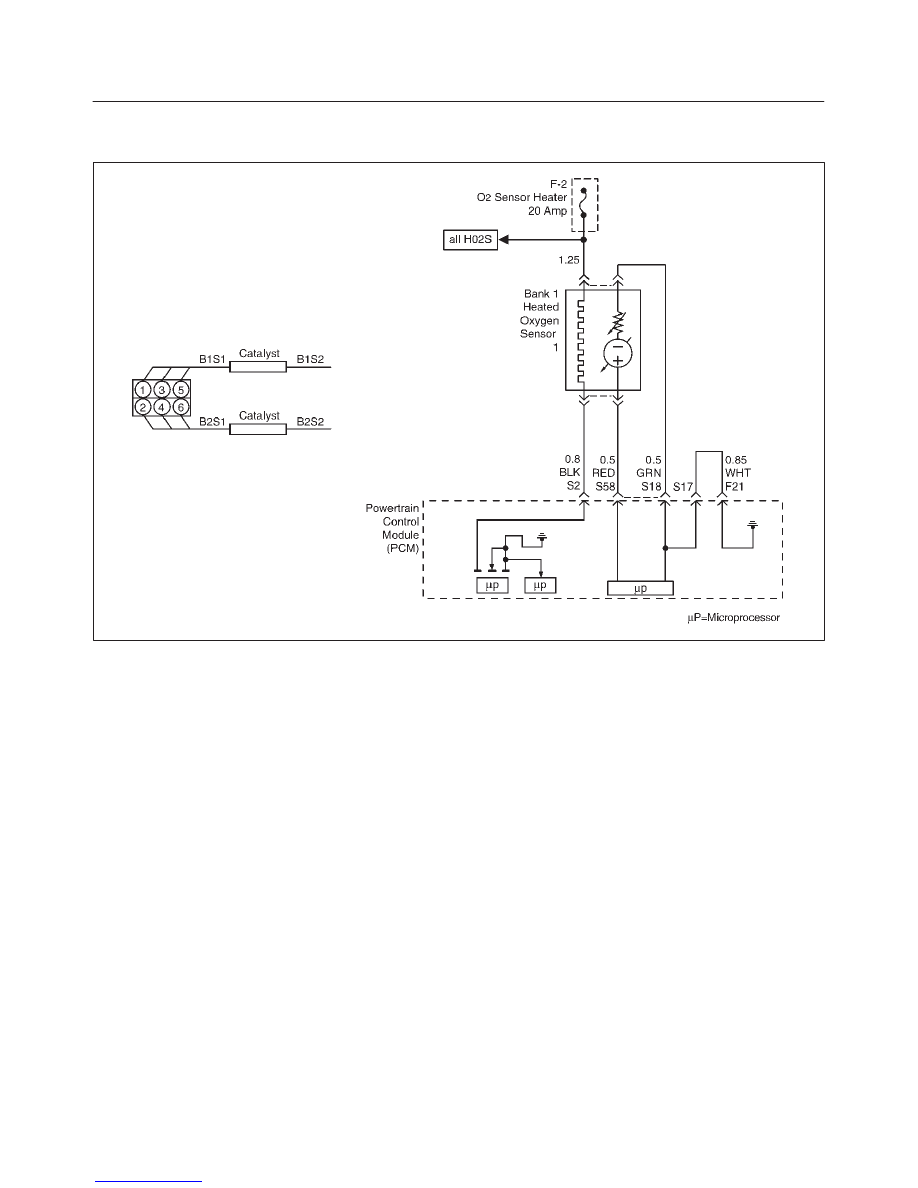

TROOPER 6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC)

P1167 Fuel System Rich During Decel Fuel Cut Off (Bank 1)

D06RY00171

Circuit Description

The powertrain control module (PCM) continuously

monitors the heated oxygen sensor (HO2S) activity for 90

seconds after “closed loop” has been enabled. During the

monitoring period the powertrain control module (PCM)

counts the number of times a rich to lean and respones is

indicated and adds the amountof time it look to complete

all rich to lean transisitions and lean to rich transitions.

This code detects if Bank1 02 sensor indicated rich

exhaust while in Decel Fuel Cut Off (DFCO) for fuel

control sensors.

Conditions for setting the DTC

D

No related DTCs.

D

The engine coolant temperature is more than 60

°

C

(140

°

F).

D

Engine is operating in “closed loop” power enrichment

mode for 3 secondes.

D

While in “power enrichment” mode the oxygen sensor

voltage remains more than 600mV in DFCO.

Action Taken When the DTC Sets

D

The PCM will not illuminate the malfunction

malfunction indicator lamp (MIL).

D

The PCM will store condition which were present when

the DTC was set as Freeze Frame and in the Failure

Records data.

Conditions for Clearing the MIL/DTC

D

A history DTC P1167 will clear after 40 cosecutive trip

cycle during which the warm up cycles have occurred

without a fault.

D

DTC P1167 can be cleared using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

D

Check for faulty fuel injectors and fuel pump.