Harley Davidson FLHRC 2006. Maintenance & Repair Manual - page 18

HOME

5.

Install the intake manifold vacuum hose onto the vacuum

fitting at the back of the fuel valve.

Hose Cutter

Part No. HD-41185

6.

Connect fuel vapor vent tube to fitting on filler neck of

fuel tank.

7.

Remove filler cap. Exercising caution to avoid pinching

harness, overflow hose and vent tube, position console

on canopy as shown in Figure 4-18. Reinstall filler cap.

Hose Clamp Pliers

8.

Install bolt (with flat washer) to secure rear of fuel tank to

Part No. HD-97087-65B

frame backbone. On FLHX models, capture console

bracket during installation. Tighten bolt to 15-20 ft-lbs

(20-27 Nm).

9.

Tighten fuel tank front mounting bolts to 15-20 ft-lbs (20-

27 Nm).

10.

Open fuel door on console. Install two Allen head screws

to secure front of console to clip nuts on canopy bracket.

Figure 4-17. Hose Cutter/Hose Clamp Pliers

Alternately tighten screws to 25-30 in-lbs (2.8-3.4 Nm). If

present, also install Allen head screw to fasten rear

flange of console to clip nut on fuel tank weldment

g. Install canopy as follows:

(absent on FLHX models). Tighten screw to 25-30 in-lbs

(2.8-3.4 Nm).

FLHX, FLHT, FLTR: See Section

8.30 FUEL

LEVEL SENDER (CARBURETED), FLHX, FLHT

11.

Connect fuel tank harness connector [13], 4-place Mul-

CANOPY, INSTALLATION, steps 1-3.

tilock, in front of battery. See Figure 4-16.

FLHR: See Section 8.30 FUEL LEVEL SENDER

12.

Insert bolt through battery negative cable (black) into

(CARBURETED), FLHR/S CANOPY, INSTALLA-

threaded hole of battery negative (-) terminal. Tighten

TION, steps 1-3.

bolt to 60-96 in-lbs (6.8-10.9 Nm).

3.

Inspect crossover hose for cuts, cracks, nicks or other

13.

Install seat. See Section 2.25 SEAT, INSTALLATION.

damage. Be sure aging has not caused the hose to

14.

Turn the handle of the fuel valve to OFF and fill the fuel

become hard and brittle. If replacing from bulk storage,

tank. Carefully inspect for leaks. Turn the valve handle to

use SAE R9 or equivalent fuel hose only. Remove old

ON and start engine. Repeat inspection.

hose and cut new hose to same length using HOSE

CUTTER (HD-41185). See Figure 4-17.

15.

Stop engine and return the valve to the OFF position.

INSTALLATION

FLHR/S

(AFTER COMPLETE REMOVAL)

1.

Work fuel tank into position aligning front flange holes

with those in left and right side of frame.

2.

Start fuel tank front mounting bolts (with flat washers).

FLHX, FLHT

3.

Route free end of crossover hose under frame backbone

1.

Work fuel tank into position aligning front flange holes

and in front of ignition coil to other side of fuel tank.

with those in left and right side of frame.

Install convoluted tubing, if removed, and new clamp

2.

Start fuel tank front mounting bolts (with flat washers).

onto hose. Install hose onto fitting at bottom of fuel tank

and crimp clamp using HOSE CLAMP PLIERS (HD-

3.

Route free end of crossover hose under frame backbone

97087-65B). See Figure 4-17.

and in front of ignition coil to other side of fuel tank.

Install convoluted tubing, if removed, and new clamp

4.

Slide new clamp onto free end of carburetor fuel inlet

onto hose. Install hose onto fitting at bottom of fuel tank

hose. Install hose onto fuel outlet fitting at side of fuel

and crimp clamp using HOSE CLAMP PLIERS (HD-

valve. Crimp clamp.

97087-65B). See Figure 4-17.

5.

Install the intake manifold vacuum hose onto the vacuum

4.

Slide new clamp onto free end of carburetor fuel inlet

fitting at the back of the fuel valve.

hose. Install hose onto fuel outlet fitting at side of fuel

valve. Crimp clamp.

6.

Connect fuel vapor vent tube to fitting at top of canopy.

2006 Touring: Fuel

4-23

HOME

f2378x8x

f2418x8

1

2

3

1

FLHX

FLHRS

2

f2381x8x

f2419x8

1

2

3

1

FLHT

FLHR

2

1.

Fuel Vapor Vent Tube (To Vapor Valve)

2.

Fuel Overflow Hose

1.

Fuel Vapor Vent Tube (To Vapor Valve)

3.

Fuel Tank Harness (To Fuel Level Sender)

2.

Main Harness Conduit (To Fuel Level Sender)

Figure 4-18. Console Cable/Hose Routing

Figure 4-19. Console Cable/Hose Routing

(FLHX, FLHT)

(FLHR/S)

10. Install bolt (with flat washer) to secure rear of fuel tank to

7.

Slide head of console mounting bolt into slot at top of

frame backbone. On FLHRS models, capture instrument

canopy.

console bracket during installation. Tighten bolt to 15-20

8.

Moving instrument console toward installed position,

ft-lbs (20-27 Nm).

install fuel level sender connector [141], 4-place Packard,

11. Tighten fuel tank front mounting bolts to 15-20 ft-lbs (20-

at top of canopy. Bend flexible clamp to capture main

27 Nm).

harness conduit.

12. Install acorn nut at top of instrument console and tighten

9.

Exercising caution to avoid pinching harness and vent

to 50-90 in-lbs (5.7-10.2 Nm). If present, also install Phil-

tube, align hole in instrument console with console

lips screw and large flat washer (absent on FLHRS mod-

mounting bolt and place into position on fuel tank. See

els). Tighten screw to 36-60 in-lbs (4.1-6.8 Nm).

Figure 4-19.

4-24

2006 Touring: Fuel

HOME

13. Connect fuel gauge to main harness. Route pin housing

and convoluted tubing forward and then inboard

between front of crossover hose fitting and bottom of fuel

tank. Mate pin and socket halves of fuel gauge connec-

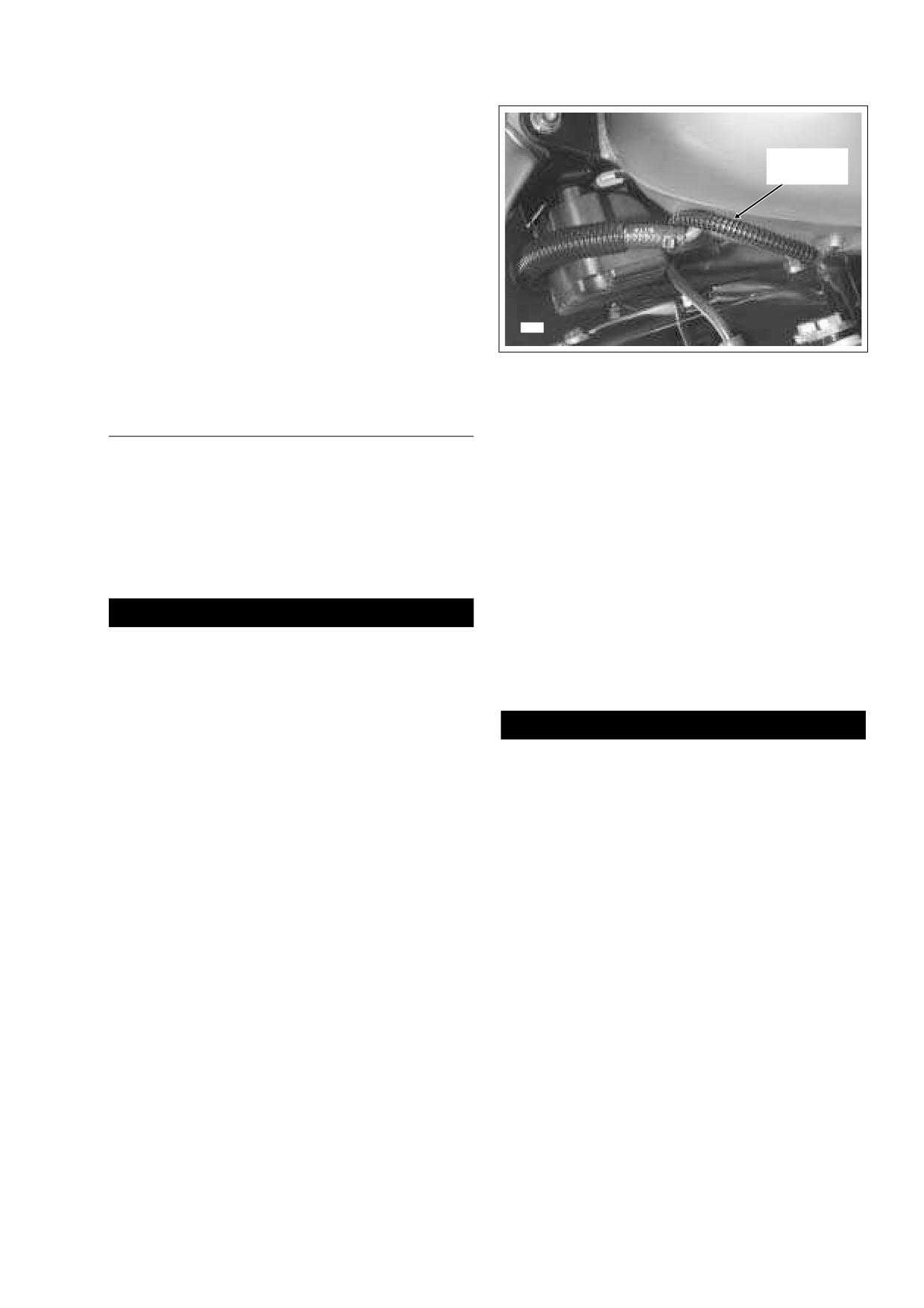

Convoluted

tor [117], 4-place Multilock. Feed connector into tunnel

Tubing

of fuel tank. See Figure 4-20.

14. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96 in-lbs (6.8-10.9 Nm).

15. Install seat. See Section 2.25 SEAT, INSTALLATION.

16. Turn the handle of the fuel valve to OFF and fill the fuel

tank. Carefully inspect for leaks. Turn the valve handle to

ON and start engine. Repeat inspection.

8870

17. Stop engine and return the valve to the OFF position.

Figure 4-20. Fuel Gauge (FLHR/S)

PARTIAL REMOVAL

8.

Raise the fuel tank approximately 2 inches. Move the

fuel tank crossover hose to the rear of the ignition coil,

so that the tank can be raised an additional 2-3 inches.

NOTE

Move fuel tank straight back and rest on frame back-

For fuel injected models, see Section 9.4 FUEL TANK (FUEL

bone.

INJECTED) for removal and installation instructions.

9.

Obtain three 1 x 2 inch wooden blocks. Raise the front of

the fuel tank off the frame backbone by placing one

FLHX, FLHT

block in the recess centered at the bottom of the tank. At

the rear of the tank, place two blocks in the recess, one

1.

Remove seat. See Section 2.25 SEAT, REMOVAL.

block on top of the other.

1WARNING

To prevent accidental vehicle start-up, which could

FLHR/S

cause death or serious injury, disconnect negative (-)

battery cable before proceeding. (00048a)

1.

Remove seat. See Section 2.25 SEAT, REMOVAL.

2.

Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

1WARNING

3.

Disconnect fuel tank harness connector [13], 4-place

Multilock, in front of battery. See Figure 4-16.

To prevent accidental vehicle start-up, which could

cause death or serious injury, disconnect negative (-)

4.

Remove two fuel tank front mounting bolts (with flat

battery cable before proceeding. (00048a)

washers) from left and right side of frame. Remove bolt

(with flat washer) to free rear of fuel tank from frame

2.

Unthread bolt and remove battery negative cable (black)

backbone. On FLHX models, removal of rear bolt also

from battery negative (-) terminal.

releases console bracket.

5.

Open fuel door on console. Remove two Allen head

3.

Remove two fuel tank front mounting bolts (with flat

screws inboard of rubber bumpers. These screws secure

washers) from left and right side of frame. Remove bolt

console to clip nuts on the canopy bracket. If present,

(with flat washer) to free rear of fuel tank from frame

also remove Allen head screw to detach flange at rear of

backbone. On FLHRS models, removal of rear bolt also

console from clip nut on fuel tank weldment (absent on

releases instrument console bracket.

FLHX models).

4.

Remove acorn nut from instrument console. If present,

6.

Lay a clean shop cloth on forward part of rear fender.

also remove Phillips screw and large flat washer (absent

Remove filler cap from neck of fuel tank. Remove con-

on FLHRS models).

sole and lay upside down on shop cloth. Reinstall filler

cap.

5.

Raise instrument console and bend back flexible clamp

on canopy to release main harness conduit. Remove

7.

Gently pry fuel vapor vent tube from fitting on filler neck

fuel level sender connector [141], 4-place Packard, at

of fuel tank. Exercise caution to avoid pulling fitting from

top of canopy.

filler neck.

2006 Touring: Fuel

4-25

HOME

present, also install Allen head screw to fasten rear

CAUTION

flange of console to clip nut on fuel tank weldment

(absent on FLHX models). Tighten screw to 25-30 in-lbs

When removing instrument console, exercise caution to

(2.8-3.4 Nm).

avoid damaging speedometer unit. Wrap console in a

clean, dry shop towel to prevent damage.

8.

Connect fuel tank harness connector [13], 4-place Mul-

tilock, in front of battery. See Figure 4-16.

6.

Secure instrument console to top of rear fender using

bungee cords.

9.

Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

7.

Remove console mounting bolt from slot at top of can-

bolt to 60-96 in-lbs (6.8-10.9 Nm).

opy.

10. Install seat. See Section 2.25 SEAT, INSTALLATION.

8.

Gently pry fuel vapor vent tube from fitting.

9.

At bottom left side of fuel tank, gently pull on convoluted

tubing to draw fuel gauge connector [117], 4-place Mul-

FLHR/S

tilock, out of tunnel. Depress button on socket terminal

side and pull apart pin and socket halves.

1.

Remove wooden blocks and move fuel tank toward its

10. Raise the fuel tank approximately 2 inches. Move the fuel

installed position. Half way down, move fuel tank cross-

tank crossover hose to the rear of the ignition coil, so that

over hose in front of ignition coil. Work fuel tank into posi-

the tank can be raised an additional 2-3 inches. Move

tion aligning front flange holes with those in left and right

fuel tank straight back and rest on frame backbone.

side of frame.

11. Obtain three 1 x 2 inch wooden blocks. Raise the front of

2.

Start fuel tank front mounting bolts (with flat washers).

the fuel tank off the frame backbone by placing one block

3.

Connect fuel vapor vent tube to fitting at top of canopy.

in the recess centered at the bottom of the tank. At the

rear of the tank, place two blocks in the recess, one block

4.

Slide head of console mounting bolt into slot at top of

on top of the other.

canopy.

5.

Moving instrument console toward installed position,

install fuel level sender connector [141], 4-place Packard,

at top of canopy. Bend flexible clamp to capture main

INSTALLATION

harness conduit.

(AFTER PARTIAL REMOVAL)

6.

Exercising caution to avoid pinching harness and vent

tube, align hole in instrument console with console

mounting bolt and place into position on fuel tank. See

FLHX, FLHT

Figure 4-19.

1.

Remove wooden blocks and move fuel tank toward its

7.

Install bolt (with flat washer) to secure rear of fuel tank to

installed position. Half way down, move fuel tank cross-

frame backbone. On FLHRS models, capture instrument

over hose in front of ignition coil. Work fuel tank into posi-

console bracket during installation. Tighten bolt to 15-20

tion aligning front flange holes with those in left and right

ft-lbs (20-27 Nm).

side of frame.

8.

Tighten fuel tank front mounting bolts to 15-20 ft-lbs (20-

2.

Start fuel tank front mounting bolts (with flat washers).

27 Nm).

3.

Connect fuel vapor vent tube to fitting on filler neck of

9.

Install acorn nut at top of instrument console and tighten

fuel tank.

to 50-90 in-lbs (5.7-10.2 Nm). If present, also install Phil-

lips screw and large flat washer (absent on FLHRS mod-

4.

Remove filler cap. Exercising caution to avoid pinching

els). Tighten screw to 36-60 in-lbs (4.1-6.8 Nm).

harness, overflow hose and vent tube, position console

on canopy as shown in Figure 4-18. Reinstall filler cap.

10.

Connect fuel gauge to main harness. Route pin housing

and convoluted tubing forward and then inboard between

5.

Install bolt (with flat washer) to secure rear of fuel tank to

front of crossover hose fitting and bottom of fuel tank.

frame backbone. On FLHX models, capture console

Mate pin and socket halves of fuel gauge connector

bracket during installation. Tighten bolt to 15-20 ft-lbs

[117], 4-place Multilock. Feed connector into tunnel of

(20-27 Nm).

fuel tank. See Figure 4-20.

6.

Tighten fuel tank front mounting bolts to 15-20 ft-lbs (20-

11.

Insert bolt through battery negative cable (black) into

27 Nm).

threaded hole of battery negative (-) terminal. Tighten

7.

Open fuel door on console. Install two Allen head screws

bolt to 60-96 in-lbs (6.8-10.9 Nm).

to secure front of console to clip nuts on canopy bracket.

Alternately tighten screws to 25-30 in-lbs (2.8-3.4 Nm). If

12.

Install seat. See Section 2.25 SEAT, INSTALLATION.

4-26

2006 Touring: Fuel

HOME

EVAPORATIVE EMISSIONS CONTROL SYSTEM

4.8

● When the engine is running, negative pressure

CALIFORNIA MODELS ONLY

(vacuum) draws the fuel vapors stored in the char-

coal canister through the purge tube to the carbure-

tor (or induction module) where they are burned as

GENERAL

part of the normal combustion process.

Harley-Davidson motorcycles sold in the state of California

● On carbureted models, fuel vapors emanating from

are equipped with an evaporative (EVAP) emissions control

the carburetor throat are drawn to the charcoal can-

system. In conformance with California Air Resource Board

ister through the clean air inlet tube connected to

(CARB) regulations, the EVAP system prevents both fuel and

the inboard side of the air cleaner backplate. Crank-

crankcase vapors from escaping into the atmosphere. See

case vapors passing from the breather tubes into

Figure 4-21.

the air filter element follow the fuel vapors to the

charcoal canister. These vapors, after passing

The EVAP system functions as follows:

through the charcoal canister, also travel through

the purge tube to the carburetor where they are

● The fuel vapor vent tube connected to a fitting on

burned.

the filler neck (top of canopy on FLHR/C/S models)

allows fuel vapors in the fuel tank to be vented

● When the engine is not running, the gravity-oper-

through the vapor valve to the charcoal canister. If

ated baffle plate at the air cleaner air inlet port

the motorcycle is tipped, the vapor valve also pre-

closes to prevent fuel and crankcase vapors from

vents the loss of gasoline through the vent tube.

escaping into the atmosphere.

f1706x4x

2

11

9

1

6

10

3

4

8

5

1.

Fuel Tank

6.

Clean Air Inlet Tube

2.

Filler Neck Fitting

7.

Charcoal Canister

(Top of Canopy on FLHR/C/S)

8.

Purge Tube

3.

Fuel Vapor Vent Tube

9.

Carburetor

7

4.

Vapor Valve

10. Fuel Valve

5.

Air Cleaner Backplate

11. Vacuum Tube

Figure 4-21. California Evaporative Emissions Control System (Carbureted Models)

2006 Touring: Fuel

4-27

HOME

f2414x4x

1WARNING

Verify that the evaporative emissions tubes/hoses do not

1

contact hot exhaust or engine parts. Tubes/hoses con-

2

tain flammable vapors that can be ignited if damaged,

possibly causing fire or explosion which could result in

death or serious injury.

4

TROUBLESHOOTING

The EVAP system has been designed to operate with a mini-

mum of maintenance. Check that all tubes/hoses are cor-

5

3

rectly routed and properly connected. Also, verify that the

tubes/hoses are not pinched or kinked.

6

VAPOR VALVE

7

NOTE

4.

Mounting Bracket

On 49 State models, the charcoal canister is absent and the

1.

Vent Tube

5.

Hole

bottom tube of the vapor valve is vented to the atmosphere.

2.

135˚ Elbow

6.

Slot

3.

Vapor Valve

7.

Cable Strap

REMOVAL

Figure 4-22. Vapor Valve Mounting Bracket

1.

Remove seat. See Section 2.25 SEAT, REMOVAL.

(Left Side View)

2. Remove left side saddlebag. See Section 2.26 SADDLE-

BAG, REMOVAL.

2.

From left side of mounting bracket, insert end of small

3.

Gently pull side cover from frame downtubes (no tools

cable strap (P/N 10065) through hole and then around

required).

body of vapor valve. Mate ends of cable strap and pull

4.

Locate vapor valve attached to mounting bracket on left

tight engaging strap in slot. Cut any excess cable strap

side of frame crossmember (in front of battery box). See

material. See Figure 4-22.

Figure 4-22.

3.

Install free end of 135˚ elbow onto fitting at top of vapor

5.

Cut cable strap to release vapor valve from mounting

valve.

bracket.

4.

Verify that vapor valve is completely vertical. Momen-

6.

Remove 135˚ elbow from fitting at top of vapor valve.

tarily push on top of vapor valve to verify that it returns to

7.

On California models, raise vapor valve slightly and pull

the completely vertical position.

vent tube from fitting at bottom of vapor valve.

NOTE

1WARNING

On 49 State models, just pull out vapor valve with bottom vent

Verify that the vent tubes do not contact hot exhaust or

tube attached. Remove vent tube from bottom fitting of vapor

engine parts. Tubes contain flammable vapors that can

valve.

be ignited if damaged, possibly causing fire or explosion,

which could result in death or serious injury.

INSTALLATION

5.

Recheck bottom vent tube routing to be sure that hose

1.

Hold vapor valve in its approximate position on right side

fittings are not pinched or kinked, and that there is no

of mounting bracket (oriented with longer fitting at the

contact with the drive belt. For California models, see

top). On California models, install vent tube onto bottom

Figure 4-24.

fitting of vapor valve.

On 49 State models, verify that vent tube at bottom of

NOTE

vapor valve is routed through opening above fuse block

bracket (upper weldment between downtubes) to out-

On 49 State models, attach vent tube to bottom fitting on

board side. Orient vent tube so that it runs downward

vapor valve. Insert vapor valve through opening above fuse

block bracket (upper weldment between downtubes), and

along the back of the forward frame downtube, where the

free end is then tucked into opening at front of lower

hold in its approximate position on right side of mounting

weldment (containing side cover grommet).

bracket.

4-28

2006 Touring: Fuel

HOME

6.

Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place

(no tools

Left Side View

required).

7.

Install left side saddlebag. See Section 2.26 SADDLE-

BAG, INSTALLATION.

2

8.

Install seat. See Section 2.25 SEAT, INSTALLATION.

4

CARB.

TANK

CHARCOAL CANISTER

1

REMOVAL

Top View

f1063b9x

1.

Remove rear fender. See Section 2.34 REAR FENDER,

REMOVAL.

1WARNING

Disconnect negative (-) battery cable first. If positive (+)

cable should contact ground with negative (-) cable con-

nected, the resulting sparks can cause a battery explo-

sion, which could result in death or serious injury.

(00049a)

2.

Unthread bolt and remove battery negative cable (black)

3

from battery negative (-) terminal.

3.

Unthread bolt and remove battery positive cable (red)

1.

Fuel Vapor Vent Tube

3.

Clean Air Inlet Tube

from battery positive (+) terminal.

2.

Purge Tube

4.

Retaining Pin

4.

Loosen T40 TORX bolt and move lip of hold-down clamp

off edge of battery. Remove battery from battery box.

Figure 4-23. Charcoal Canister

5.

Reaching into battery box, pry plastic retaining pin out of

hole on left side. See inset of Figure 4-23.

6.

Reaching in between battery box and right side frame

2.

Attach tubes to fittings on left side of canister. Install the

member, pull clean air inlet tube (to air cleaner backplate

purge tube to the carburetor (or induction module) onto

on carbureted models) from fitting on right side of char-

the top fitting stamped “CARB.” Install the fuel vapor vent

coal canister. On fuel injected models, pull 90˚ elbow

tube from the fuel tank (via the vapor valve) to the bot-

connector from fitting.

tom fitting stamped “TANK.”

7.

Moving to rear left side of motorcycle, center a flashlight

on drive belt and direct the beam forward. Note the two

3.

Moving to rear right side of motorcycle, attach clean air

tube connections on the left side of the canister. See

inlet tube (to air cleaner backplate on carbureted mod-

Figure 4-23. Reaching in between battery box and frame

els) to fitting on right side of canister. On fuel injected

member, pull tubes from canister.

models, install 90˚ elbow connector with the free end

8.

With the handle of a rubber mallet, rap canister toward

pointing down.

left side of motorcycle until tongue at top of canister is

NOTE

free of grooves in bottom of battery box. From right side

of motorcycle, pull canister out of opening between bat-

The clean air inlet tube is absent on fuel injected models.

tery box and frame member.

4.

Place battery in battery box, terminal side forward.

INSTALLATION

1WARNING

1.

With tongued side up, slide canister into cavity using

opening between battery box and right side frame mem-

Connect positive (+) battery cable first. If positive (+)

ber. Start tongue into grooves on left side of battery box.

cable should contact ground with negative (-) cable con-

Push the canister toward the right side of the motorcycle

nected, the resulting sparks can cause a battery explo-

until fully engaged. Snap plastic retaining pin into hole at

sion, which could result in death or serious injury.

bottom of battery box (left side) to lock position of canis-

(00068a)

ter. See inset of Figure 4-23.

2006 Touring: Fuel

4-29

HOME

3

2

1

1.

Fuel Vapor Vent Tube (From Filler Neck of Fuel Tank Via Vapor Valve)

2.

Purge Tube (To Carburetor or Induction Module)

3.

Clean Air Inlet Tube (From Air Cleaner Backplate on Carbureted Models Only)

f1884x4x

Figure 4-24. Charcoal Canister Tube/Hose Routing (Left Side View)

5.

Insert bolt through battery positive cable

(red) into

Purge Tube:

threaded hole of battery positive (+) terminal. Tighten

bolt to 60-96 in-lbs (6.8-10.9 Nm).

From top fitting on left side of charcoal canister (stamped

“CARB”), purge tube is routed forward where it runs under

6.

Insert bolt through battery negative cable (black) into

frame crossmember, and then angles upward between cross-

threaded hole of battery negative (-) terminal. Tighten

member and inner primary housing. Captured in clip

bolt to 60-96 in-lbs (6.8-10.9 Nm).

anchored in hole at front of crossmember (rear and inboard of

cruise hole), purge tube goes over crossover pipe, runs along

7.

Rotate hold-down clamp so that the lip (with rubber pad)

left side of rear cylinder rocker cover and into tunnel of fuel

rests on the edge of the battery. Tighten the T40 TORX

tank. It then crosses to right side of motorcycle just to the rear

bolt to 15-20 ft-lbs (20-27 Nm).

of the top engine mounting bracket, where it connects to a fit-

ting on the carburetor (or induction module). See Figure 4-24.

8.

Install rear fender. See Section 2.34 REAR FENDER,

INSTALLATION.

Fuel Vapor Vent Tube:

From bottom fitting on left side of charcoal canister (stamped

“TANK”), vent tube is routed forward and then upward in front

Charcoal Canister Hose Routing

of battery box to bottom fitting on vapor valve mounted to rear

of upper frame crossmember.

1WARNING

Another section connected to top fitting of vapor valve follows

the inboard side of the main harness bundle, where it is cap-

Verify that the vent tubes do not contact hot exhaust or

tured in anchored cable strap on left side of frame backbone

engine parts. Tubes contain flammable vapors that can

before passing under console pod/instrument console to fit-

be ignited if damaged, possibly causing fire or explosion,

ting on filler neck of fuel tank (top of canopy on FLHR/C/S

which could result in death or serious injury.

models).

4-30

2006 Touring: Fuel

HOME

Clean Air Inlet Tube:

From 90˚ elbow connector on right side of charcoal canister,

clean air inlet tube runs forward under frame crossmember

and then upward (inboard of starter connections) following

angle of crossmember, where it is routed over crossover pipe

and rear cylinder rocker cover into tunnel of fuel tank on right

side of frame backbone. Tube turns right just to the rear of

the top engine mounting bracket, where it connects to fitting

on inboard side of air cleaner backplate.

NOTE

The clean air inlet tube is absent on fuel injected models, so

the fitting on the right side of the canister terminates in a 90˚

elbow connector (the free end pointing down).

2006 Touring: Fuel

4-31

HOME

NOTES

4-32

2006 Touring: Fuel

Table Of Contents

ELECTRIC STARTER

5

SUBJECT

PAGE NO.

5.1 Specifications

5-1

5.2 Starter System

5-2

5.3 Starter Relay

5-4

5.4 Starter

5-6

5.5 Starter Solenoid

5-13

5.6 Starter Jackshaft

5-14

NOTE

See the 2006 ELECTRICAL DIAGNOSTIC MANUAL

(Part No. 99497-06) for all SYSTEM DIAGNOSIS and

ELECTRICAL TROUBLESHOOTING information.

HOME

SPECIFICATIONS

5.1

STARTER

TORQUE VALUES

Item

Specification

Item

ft/in-lbs

Nm

Thru-bolts

39-65 in-lbs

4.4-7.3 Nm

Free (no load) speed

3000 rpm (min.) @ 11.5 V

End cover mounting

Free (no load) current

90 amp (max.) @ 11.5V

50-60 in-lbs

5.6-6.8 Nm

bracket

Stall torque

8.0 ft-lbs (10.8 Nm) @ 2.4 V

End cover center screw

90-110 in-lbs

10.2-12.4 Nm

Battery cable terminal

60-96 in-lbs

6.8-10.9 Nm

bolts

SERVICE WEAR LIMITS

Starter front and rear

14-18 ft-lbs

19-24 Nm

mounting screws

Oil filler spout allen head

84-132 in-lbs

9.5-14.9 Nm

Item

IN.

MM

socket screws

Starter jackshaft bolt

60-80 in-lbs

6.8-9.0 Nm

Brush length minimum

0.433

11

Solenoid terminal nut

70-90 in-lbs

7.9-10.2 Nm

Commutator diameter

1.141

29

minimum

2006 Touring: Starter

5-1

HOME

STARTER SYSTEM

5.2

The magnetic forces of the pull-in and hold-in windings in the

GENERAL

solenoid, pull the plunger and cause it to shift to the left, so

that the pinion gear is engaged with the clutch ring gear. At

The starter is made up of an armature, field winding assem-

the same time, the main solenoid contacts are closed and

bly, solenoid, drive assembly, idler gear, and drive housing.

battery current flows directly through the field windings to the

The starter motor torque is increased through gear reduction.

armature and to ground. Simultaneously, the pull-in winding

The gear reduction consists of the drive pinion on the arma-

is opened.

ture, an idler gear, and a clutch gear in the drive housing. The

The current continues flowing through the hold-in winding,

idler gear is supported by rollers and the clutch gear is part of

keeping the main solenoid contacts closed. At this point the

the overrunning clutch/drive assembly.

starter begins to crank the engine.

The overrunning clutch is the part which engages and drives

the clutch ring gear. It also prevents the starter from overrun-

After the engine has started, the pinion gear turns freely on

ning. The field windings are connected in series with the

the pinion shaft through the action of the overrunning clutch

armature through brushes and commutator segments.

which prevents the armature overrunning by the rotation of

the clutch ring gear.

The starter relay is a non-repairable part and must be

replaced if it malfunctions.

When the starter switch is released, the current of the hold-in

winding is fed through the main solenoid contacts and the

direction of the current in the pull-in winding is reversed. The

Operation (Figure 5-1)

solenoid plunger is returned to its original position by the

return spring, disengaging the pinion gear from the clutch

When the starter switch is pushed, the starter relay is acti-

ring gear.

vated and battery current flows into the pull-in winding and

the hold-in winding, to ground.

5-2

2006 Touring: Starter

HOME

STARTER AT MOMENT STARTER SWITCH IS CLOSED

Armature

Field winding

Brush

Idler gear

Ball

bearing

Pinion

gear

Plunger

Main

contacts

Hold-In

Overrunning

Pull-In

winding

Clutch

clutch

winding

Battery

ring gear

Start

circuit. See

wiring

diagram.

STARTER DURING CRANKING

Armature

Field winding

Brush

Idler gear

Pinion

Ball

gear

bearing

Plunger

Main

contacts

Overrunning

Hold-in

Pull-In

clutch

winding

winding

Battery

Clutch

ring gear

Start circuit.

See wiring

diagram

Figure 5-1. Starter Operation

2006 Touring: Starter

5-3

HOME

STARTER RELAY

5.3

REMOVAL

FLHR/C/S

FLHR/C/S

[124]

1.

Remove left side saddlebag. See Section 2.26 SAD-

DLEBAG, REMOVAL.

2.

Gently pull side cover from frame downtubes (no tools

required).

3.

Depress latches on maxi-fuse holder and then slide

cover rearward to disengage tongue from groove in fuse

block cover.

[123]

4.

Pull fuse block from tabs on mounting panel. Tabs on

panel fit into slots on each side of fuse block cover.

f2210x8x

NOTE

The fuse block cover also serves as the spare fuse holder.

One spare 10 amp and 15 amp fuse are provided.

FLHX, FLHT/C/U, FLTR

5.

Remove the fuse block cover. Raise lipped side slightly

[126]

[123]

to disengage slots from tabs on fuse block.

6.

Pull relay from slots in fuse block. See upper frame of

Figure 5-2.

FLHX, FLHT/C/U, FLTR

1.

Remove seat. See Section 2.25 SEAT, REMOVAL.

2.

Locate the starter relay installed in cavity of frame cross-

member at rear of battery box. See lower frame of Fig-

ure 5-2.

3.

Place a finger on the rubber molding to hold it in posi-

tion, and using a needle nose pliers, carefully pull on tab

to release starter relay.

NOTE

Since the position of the relays may be reversed, check the

f2192x8x

wire tag or color for positive identification. Starter relay can

always be positively identified by heavy gauge GREEN wire.

4.

Remove harness connector from bottom of relay.

[123]

Starter Relay

[124]

Brake Light Relay

[126]

Ignition Keyswitch Relay

INSTALLATION

Figure 5-2. Locate Starter Relay

FLHR/C/S

4.

Slide

maxi-fuse cover forward to engage

tongue

in

1.

Install new relay in fuse block.

groove of fuse block cover and then insert maxi-fuse

2.

Slide cover over fuse block until slots fully engage tabs

holder into cover until latches engage.

on block.

5.

Align barbed studs in side cover with grommets in frame

3.

Slide fuse block into position on mounting panel. Tabs on

downtubes and push firmly into place

(no tools

panel fit into slots on each side of fuse block cover.

required).

5-4

2006 Touring: Starter

HOME

6.

Install left side saddlebag. See Section 2.26 SADDLE-

FLHX, FLHT/C/U, FLTR

BAG, INSTALLATION.

1.

Install harness connector at bottom of new relay.

2.

Place a finger on the molding to hold it in position and

push on relay until seated in cavity of frame cross-

member.

3.

Install seat. See Section 2.25 SEAT, INSTALLATION.

2006 Touring: Starter

5-5

HOME

STARTER

5.4

REMOVAL

f2268x8x

Frame Hole

Frame

Cruise Cable

Cross Member

Routing Only

1.

Remove seat. See Section 2.25 SEAT, REMOVAL.

1WARNING

To prevent accidental vehicle start-up, which could

cause death or serious injury, disconnect negative (-)

battery cable before proceeding. (00048a)

2.

Unthread bolt and remove battery negative cable (black)

Positive

from battery negative (-) terminal.

Battery Cable

3.

Remove the primary chaincase cover. See Section 6.5

PRIMARY CHAINCASE, REMOVAL, steps 3-8.

4.

Bend tab on lockplate away from head of jackshaft bolt.

5.

Holding pinion gear to prevent rotation, remove the jack-

shaft bolt with lockplate and thrust washer.

Negative

6.

From right side of motorcycle, remove starter front

Battery Cable

mounting screw with lockwasher. Remove rear mounting

screw with lockwasher (and battery negative cable ring

terminal). Remove Keps nut from stud of bracket tab and

remove exhaust support bracket.

Main Power

7.

Pull back rubber boot and remove flange nut from starter

To Maxi-Fuse

post. Remove main power and battery positive cable

ring terminals from starter post. See Figure 5-3.

Figure 5-3. Battery Cable Routing (Right Side View)

8.

Depress external latch and pull solenoid connector from

top of starter housing.

2.

From right side of motorcycle, tilt starter and work into its

9.

Locate oil filler plug/dipstick on right side of motorcycle

installed position. Starter output shaft coupling must

at top of transmission case. To remove the oil filler plug,

remain on shaft and mate to starter jackshaft. See Sec-

pull steadily while moving plug back and forth.

tion 5.6 STARTER JACKSHAFT, if necessary.

10. Remove the starter from the right side of the motorcycle,

3.

Install oil filler plug/dipstick at top of transmission case

carefully sliding it through the space between the

on right side of motorcycle.

exhaust pipe and side cover.

4.

Install slot of exhaust support bracket onto stud of

bracket tab aligning other holes with those in starter

NOTE

flange. Start Keps nut on stud.

If necessary, remove allen screw and decorative chrome

5.

Engaging hole in exhaust support bracket, install starter

cover to facilitate starter removal.

front mounting screw with lockwasher. Install rear

mounting screw with lockwasher (and battery negative

11. Remove the coupling from the starter motor output shaft,

cable ring terminal) in the same manner.

if necessary.

6.

Alternately tighten starter front and rear mounting

12. Before disassembly, perform tests on the assembled

screws to 14-18 ft-lbs (19-24 Nm). Tighten Keps nut on

starter. See DISASSEMBLY, TESTING AND REPAIR in

stud of bracket tab.

this section.

7.

Install battery positive and main power cable ring termi-

nals onto starter post. Install flange nut and tighten to

70-90 in-lbs (7.9-10.2 Nm). Pull down rubber boot over

INSTALLATION

terminal connections on starter post. See Figure 5-3.

8.

Snap solenoid connector to terminal at top of starter

1.

Inspect the retaining ring within the output shaft coupling

housing.

for damage or distortion. Replace as necessary. With the

NOTE

counterbore on the outboard side, install the coupling on

If removed, install allen screw to fasten decorative chrome

the starter motor output shaft, if removed.

cover to starter.

5-6

2006 Touring: Starter

HOME

1.

Field wire

15. Drive assembly/overrunning clutch

2.

Thru-bolt (2)

16. Idler gear

3.

Field coil

17. Idler gear bearing & cage

4.

End cap

18. O-ring

5.

End cap screw (2)

19. Spring

6.

Brush spring (4)

20. Shaft

7.

Brushes

21. Return spring

8.

Brush holder

22. Ball

4

5

9.

Armature

23. O-ring (2)

6

10. Armature bearings

11. Drive housing mounting screw (2)

7

23

12. Lockwasher (2)

2

13. Drive housing

3

14. Solenoid housing

23

7

10

9

8

10

14

1

21

22

16

17

20

19

15

18

12

13

11

f1107axx

Figure 5-4. Starter

9.

Slide lockplate and new thrust washer onto jackshaft

12. Install the primary chaincase cover. See Section 6.5

bolt, if removed. Insert bolt into jackshaft bore.

PRIMARY CHAINCASE, INSTALLATION, steps 20-31.

10.

Insert key on lockplate through slot in thrust washer and

into keyway on jackshaft. Thread the jackshaft bolt into

13. Insert bolt through battery negative cable (black) into

the starter shaft making sure that the lockplate key

threaded hole of battery negative (-) terminal. Tighten

remains in the keyway.

bolt to 60-96 in-lbs (6.8-10.9 Nm).

11.

Holding pinion gear to prevent rotation, tighten jackshaft

bolt to 60-80 in-lbs (6.8-9.0 Nm). Bend tab on lockplate

14. Install seat. See Section 2.25 SEAT, INSTALLATION.

against flat of bolt head to secure.

2006 Touring: Starter

5-7

HOME

3.

See Figures 5-7 and 5-8. Remove the end cap screws

DISASSEMBLY, TESTING AND

and cap.

REPAIR

1.

See Figures 5-4 and 5-5. Disconnect field wire (1).

3500

3497

Figure 5-7. Remove End Cap Screws and O-Rings

Figure 5-5. Remove Thru-Bolts

3501

2.

See Figures

5-4 and

5-6. Remove thru-bolts

(2).

Remove field coil (3) and end cap (4).

3498

Figure 5-8. Remove End Cap

4.

See Figures 5-4 and 5-9. Disengage brush springs (6)

and pull field coil brushes (7) out of brush holders (8).

3502

Figure 5-6. Remove Field Coil and Cap

Figure 5-9. Remove Brush Holder

5-8

2006 Touring: Starter