Ford Mondeo (petrol engines). Manual - part 111

Chapter 11 Bodywork and fittings

Body side-trim mouldings and adhesive emblems - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bonnet - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . .

8

Bonnet lock - removal, refitting and adjustment . . . . . . . . . . . . . . . . 10

Bonnet release cable and lever - removal and refitting . . . . . . . . . . .

9

Boot lid - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Boot lid lock components - removal and refitting . . . . . . . . . . . . . . . 19

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Central locking system components - testing, removal and refitting . 23

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 30

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Door handle and lock components - removal and refitting . . . . . . . . 14

Door inner trim panel - removal and refitting . . . . . . . . . . . . . . . . . . 11

Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . . 12

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . 13

Exterior mirror and glass - removal and refitting . . . . . . . . . . . . . . . . 16

Facia - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Glovebox - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Interior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 17

Interior trim panels - removal and refitting . . . . . . . . . . . . . . . . . . . . 29

Maintenance - bodywork and underframe . . . . . . . . . . . . . . . . . . . .

2

Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . .

3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Overhead console - removal and refitting . . . . . . . . . . . . . . . . . . . . . 31

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .

7

Seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sunroof - general information and adjustment . . . . . . . . . . . . . . . . . 26

Tailgate - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tailgate lock components - removal and refitting . . . . . . . . . . . . . . . 22

Tailgate support strut - removal and refitting . . . . . . . . . . . . . . . . . . 21

Wheel arch liner - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 34

Windscreen and fixed windows - removal and refitting . . . . . . . . . . 24

Torque wrench settings

Nm

lbf ft

Bonnet and tailgate hinges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24

18

Boot lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

7

Front seat mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

28

Seat belt mounting nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

28

Bumper mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

7

11•1

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult, suitable

for competent DIY

mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications

Contents

11

The bodyshell and underframe on all

models is of all-steel welded construction,

incorporating progressive crumple zones at

the front and rear, and a rigid centre safety

cell. The bulkhead behind the engine

compartment incorporates crash grooves

which determine its energy-absorption

characteristics, and special beams to prevent

the intrusion of the front wheels into the

passenger compartment during a serious

accident. All passenger doors incorporate

side impact bars.

All sheet metal surfaces which are prone to

corrosion are galvanized. The painting

process includes a base colour which closely

matches the final topcoat, so that any stone

damage is not noticeable.

Hatchback, Saloon and Estate versions are

available. The front section of the vehicle up to

the “B” pillar is identical on all models.

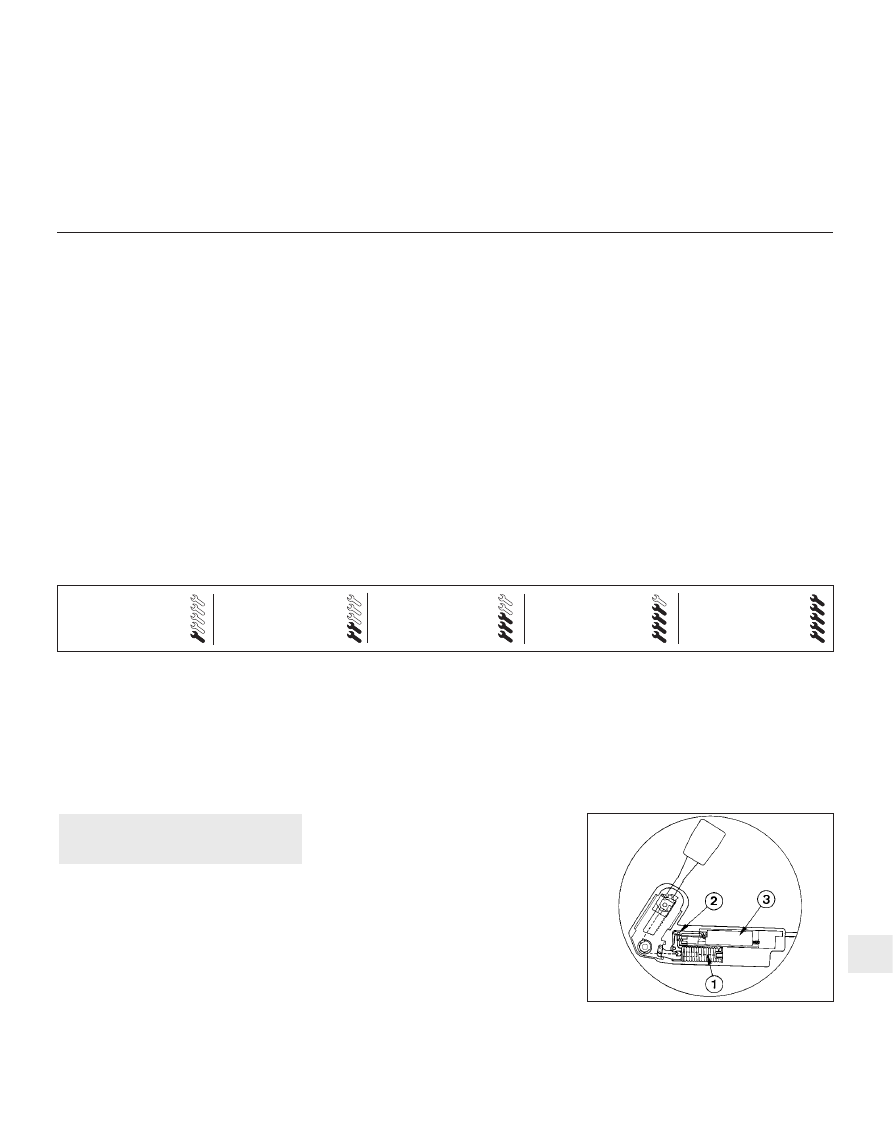

Automatic seat belts are fitted to all models,

and the front seat belt stalks are mounted on

automatic tensioners (also known as

“grabbers”)

(see illustration). In the event of a

serious front impact, a spring mass sensor

releases a coil spring which pulls the stalk

buckle downwards and tensions the seat belt.

It is not possible to reset the tensioner once

fired, and it must therefore be renewed.

In the UK, central locking is standard on all

1 General information

1.4 Automatic seat belt tensioner

1 Coil spring

3 Spring mass sensor

2 Lever system