Ford Mondeo (petrol engines). Manual - part 108

Refitting

15 Locate the strut assembly (together with

the coil spring compressor tool) under the

wheel arch, and locate the bracket on the

bump stop on the rear suspension

crossmember. Insert the two bolts securing

the upper mounting to the underbody tower,

and tighten them to the specified torque.

16 Carefully release the coil spring

compressor tool, making sure that the spring

locates correctly in the upper and lower seats,

and that the strut bracket locates on the

crossmember bump stop. The bump stop is

tapered inwards, and the strut bracket should

be fully engaged with it before releasing the

coil spring.

17 Raise the knuckle and engage it with the

strut, then insert the clamp bolt and tighten to

the specified torque.

18 Reconnect the front and rear lower arms

to the knuckle, and finger-tighten the bolts at

this stage.

19 Reconnect the tie-bar to the bottom of the

knuckle, and finger-tighten the bolt at this

stage.

20 Refit the anti-roll bar link to the lower arm,

and tighten the nut to the specified torque.

21 On disc brake models, refit the caliper

bracket to the knuckle, and tighten the

mounting bolts to the specified torque (see

Chapter 9). Make sure that the flexible brake

hose is not twisted.

22 On drum brake models, connect the

flexible hose to the strut, insert the clip, then

insert the rigid brake line and tighten the union

nut. Remove the brake hose clamp, then

bleed the hydraulic brake circuit as described

in Chapter 9.

23 Where applicable, reconnect the wiring

multi-plug for the adaptive damping, and clip

the wiring to the strut.

24 Where applicable, refit the ABS sensor as

described in Chapter 9, and clip the wiring to

the strut.

25 Refit the wheel, and lower the vehicle to

the ground.

26 With the weight of the vehicle on the rear

suspension, fully tighten the lower arm and

tie-bar mounting bolts.

1 The procedure is similar to that for the front

suspension strut, and reference should be made

to Section 5. Note that the spring compressor

tools will already be in position on the coil spring

following the removal operation. Refer also to

the accompanying illustrations for details of the

separate components (see illustrations).

Removal

1 Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove both rear wheels.

2 Unscrew the nuts securing the anti-roll bar

links to the front lower arms on both sides.

Hold the upper part of the links with a spanner

while loosening the nuts. Recover the rubber

bushes (see illustrations).

13 Rear anti-roll bar and links

(Saloon/Hatchback models) -

removal and refitting

12 Rear suspension strut

(Saloon/Hatchback models) -

overhaul

10•12 Suspension and steering systems

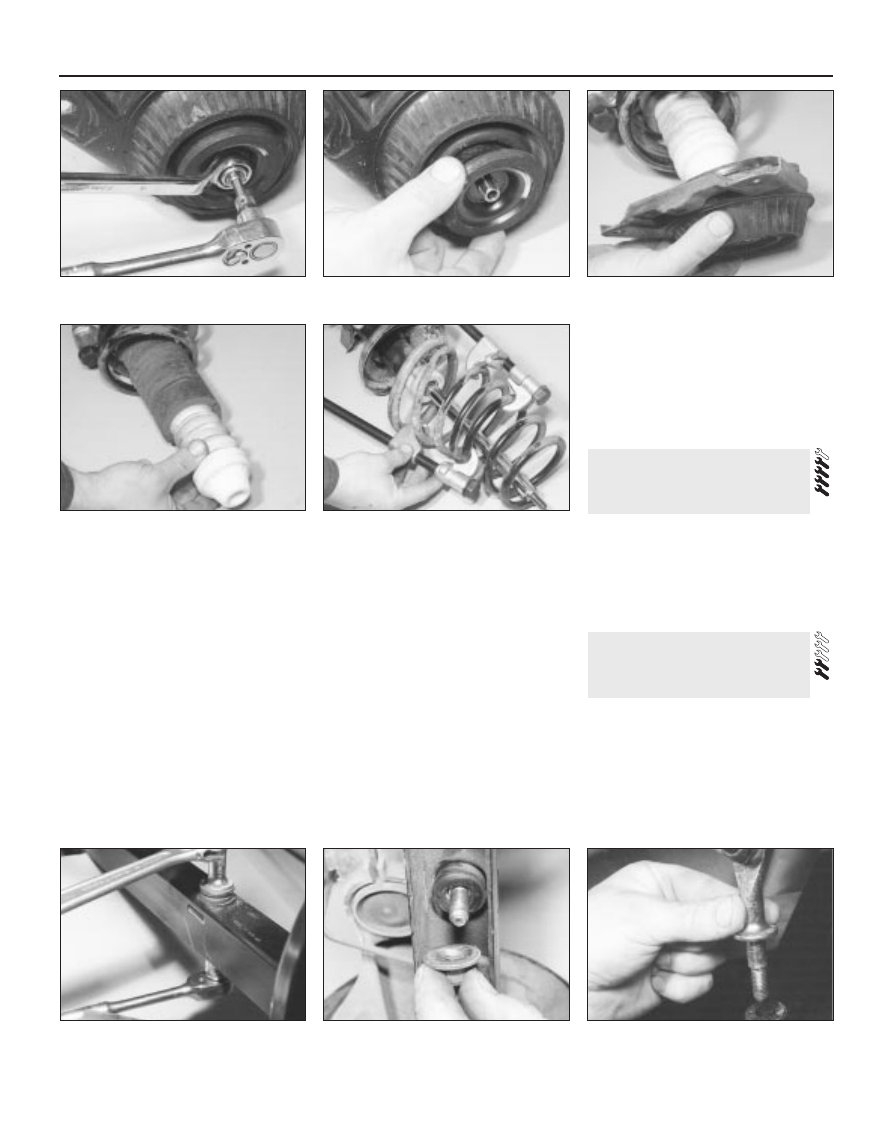

12.1A Rear strut dismantling - unscrew

the upper mounting nut . . .

12.1B . . . remove the cup . . .

12.1C . . . upper mounting bracket and

seat . . .

13.2A Loosen the nut . . .

13.2B . . . remove the nut and rubber

bush . . .

12.1D . . . gaiter and bump stop . . .

12.1E . . . and coil spring

13.2C . . . and remove the anti-roll bar link

from the lower arm