Ford Mondeo (petrol engines). Manual - part 102

caliper bore, to provide room for the new

brake pads. A C-clamp can be used to

accomplish this. As the piston is depressed to

the bottom of the caliper bore, the fluid in the

master cylinder will rise slightly. Make sure

that there is sufficient space in the brake fluid

reservoir to accept the displaced fluid, and if

necessary, syphon some off first.

6 Fit the new pads using a reversal of the

removal procedure, but tighten the guide

bolts to the torque wrench setting given in the

Specifications at the beginning of this

Chapter.

7 On completion, firmly depress the brake

pedal a few times, to bring the pads to their

normal working position. Check the level of

the brake fluid in the reservoir, and top-up if

necessary.

8 Give the vehicle a short road test, to make

sure that the brakes are functioning correctly,

and to bed-in the new linings to the contours

of the disc. New linings will not provide

maximum braking efficiency until they have

bedded-in; avoid heavy braking as far as

possible for the first hundred miles or so.

Note: Refer to the warning at the beginning of

the previous Section before proceeding.

Removal

1 Apply the handbrake. Loosen the front

wheel nuts, jack up the front of the vehicle

and support it on axle stands. Remove the

appropriate front wheel.

2 Fit a brake hose clamp to the flexible hose

leading to the front brake caliper. This will

minimise brake fluid loss during subsequent

operations (see illustration).

3 Loosen (but do not completely unscrew) the

union on the caliper end of the flexible brake

hose (see illustration).

4 Remove the front brake pads as described

in Section 2.

3 Front brake caliper -

removal, overhaul and refitting

9•4 Braking system

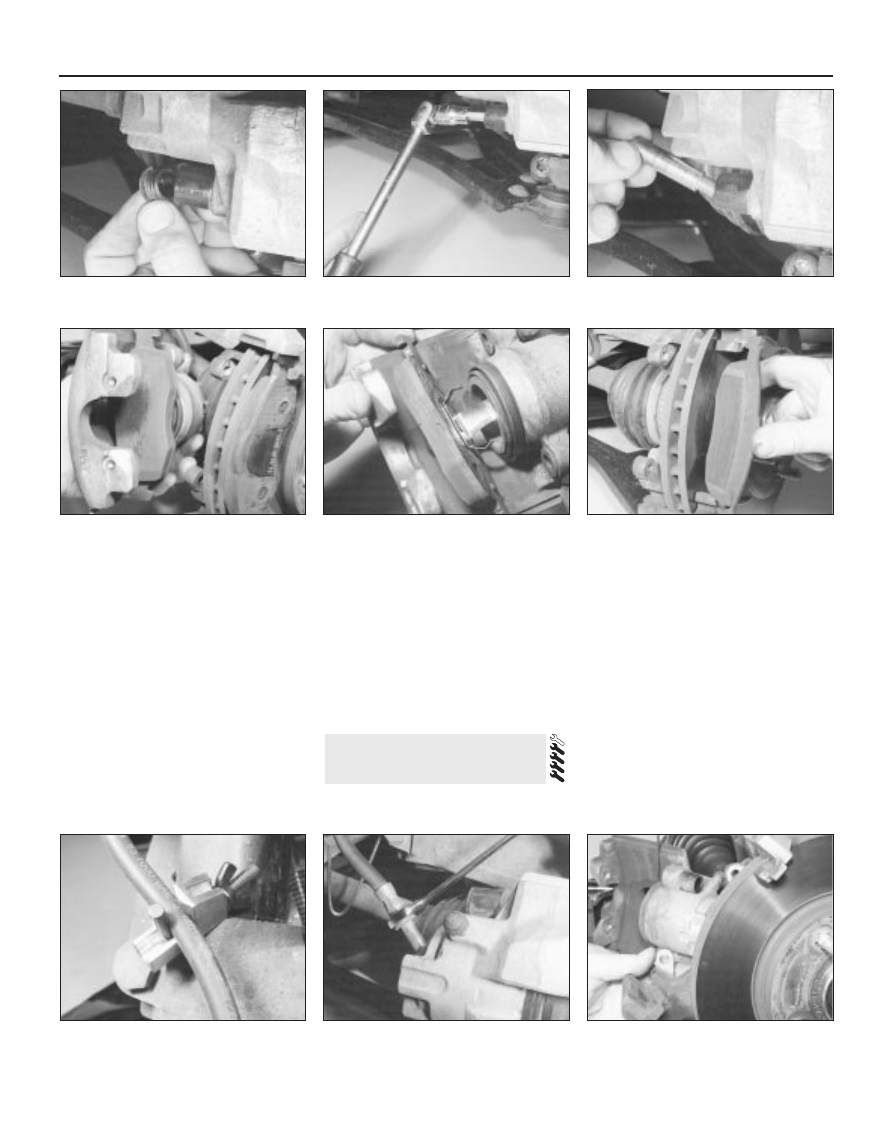

2.3B Prise the plastic covers from the

ends of the two guide pins

2.3C Using a 7 mm Allen key, unscrew . . .

2.3D . . . and remove the guide bolts

securing the caliper to the carrier bracket

2.3E Withdraw the caliper from the disc,

and support it on an axle stand to avoid

straining the hydraulic hose. The outer pad

will normally remain in position against the

disc, but the inner pad will stay attached to

the piston in the caliper

2.3F Pull the inner pad from the piston in

the caliper

3.2 Brake hose clamp fitted to the front

flexible brake hose

3.3 Loosening the flexible brake hose at

the caliper

3.6 Removing the caliper carrier bracket

2.3G Remove the outer pad from the

caliper frame. Brush all dust and dirt from

the caliper, pads and disc, but do not

inhale it, as it may be harmful to health.

Scrape any corrosion from the disc.