Ford Mondeo (petrol engines). Manual - part 95

3 Using an ohmmeter, measure the

resistance of the coil’s primary windings,

connecting the meter between the coil’s

terminal pins as follows. Measure first from

one outer pin to the centre pin, then from the

other outer pin to the centre. Compare your

readings with the coil primary resistance listed

in the Specifications Section at the beginning

of this Chapter.

4 Disconnect the spark plug (HT) leads - note

their connections or label them carefully, as

described in Chapter 1. Use the meter to

check that there is continuity (ie, a resistance

corresponding to that of the coil secondary

winding) between each pair of (HT) lead

terminals; Nos 1 and 4 terminals are

connected by their secondary winding, as are

Nos 2 and 3. Now switch to the highest

resistance scale, and check that there is no

continuity between either pair of terminals and

the other - ie, there should be infinite

resistance between terminals 1 and 2, or 4

and 3 - and between any terminal and earth.

5 If either of the above tests yield resistance

values outside the specified amount, or

results other than those described, renew the

coil. Any further testing should be left to a

dealer service department or other qualified

repair facility.

Removal and refitting

6 Disconnect the battery negative (earth) lead

- see Section 1.

7 Remove the air mass meter and resonator -

refer to Chapter 4.

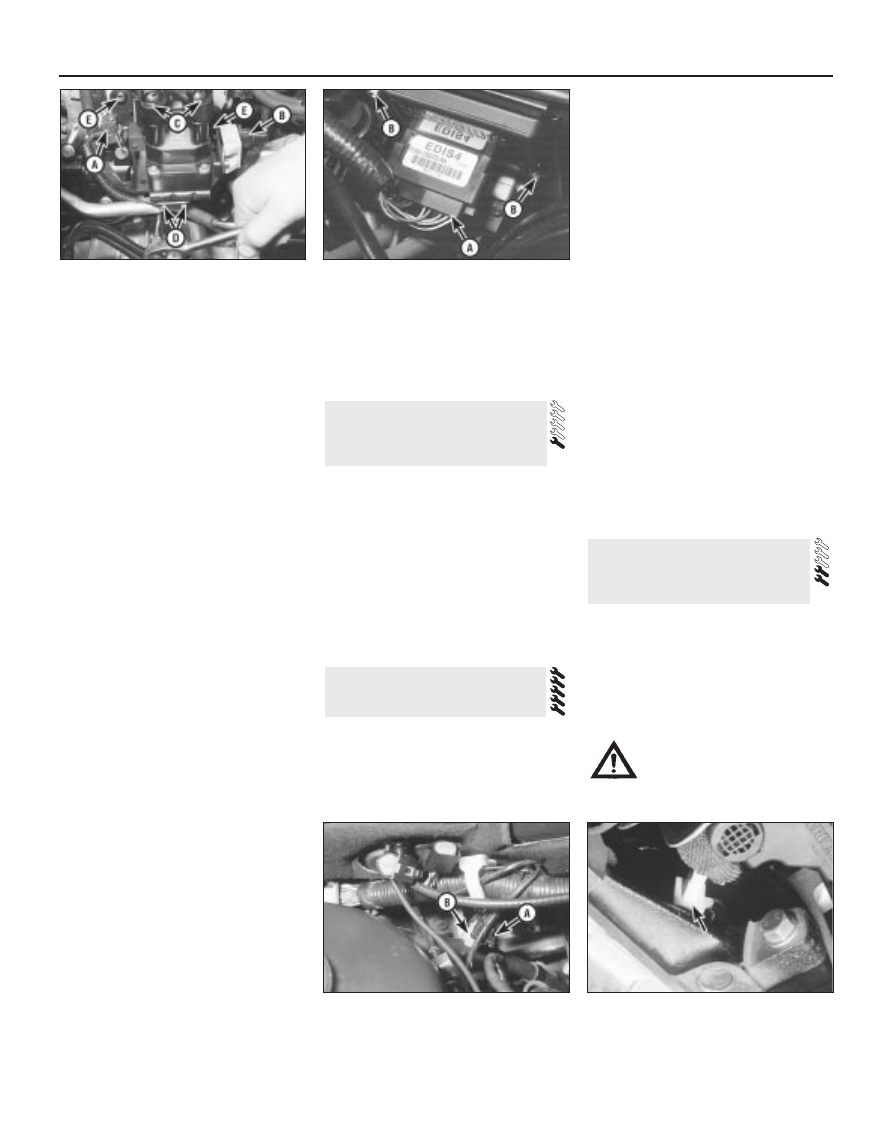

8 Unplug the electrical connector from each

side of the coil, then disconnect the spark

plug (HT) leads - note their connections or

label them carefully, as described in Chapter

1.

9 Undo the two screws securing the EGR

pipe to the coil bracket, then remove the coil

mounting (Torx-type) screws. Withdraw the

coil assembly from the cylinder head (see

illustration).

10 The suppressor can be unbolted from the

mounting bracket, if required; note that the

coil and bracket are only available as a single

unit.

11 Refitting is the reverse of the removal

procedure. Ensure that the spark plug (HT)

leads are correctly reconnected, and tighten

the coil screws securely.

Note: See Chapter 6 for component location

illustrations.

1 Disconnect the battery negative (earth) lead

- see Section 1.

2 If better access is required, remove the

resonator (see Chapter 4).

3 Unplug the electrical connector from the

module (see illustration).

4 Remove the retaining screws, and detach

the module from the bulkhead mounting

bracket.

5 Refitting is the reverse of the removal

procedure.

As noted in Section 4, the ignition timing is

controlled entirely by the ECU (acting with the

ignition module, on models with automatic

transmission), and cannot be adjusted. The

value quoted in the Specifications Section of

this Chapter is for reference only, and may

vary significantly if “checked” by simply

connecting a timing light to the system and

running the engine at idle speed.

Not only can the ignition timing not be

adjusted, it cannot be checked either, except

with the use of special diagnostic equipment

(see Chapter 6) - this makes it a task for a

Ford dealer service department.

Owners who are taking their vehicles

abroad should note that the ignition system is

set for the engine to use petrol of 95 RON

octane rating by fitting a “plug-in bridge” to

the service connector on the engine

compartment bulkhead (see illustration).

Removing the “plug-in bridge” retards the

ignition timing - by an unspecified value - to

allow the engine to run on 91 RON fuel. This

grade of fuel is the “Regular” or “Normal”

widely used abroad, but not at present

available in the UK. If you are taking the

vehicle abroad, seek the advice of a Ford

dealer (or of one of the motoring

organisations). This will ensure that you are

familiar with the grades of fuel you are likely to

find (and the sometimes confusing names for

those grades), and that the vehicle is set

correctly at all times for the fuel used. Note:

The octane ratings mentioned above are both,

of course, for unleaded petrol. Do not use

leaded petrol at any time in a vehicle equipped

with a catalytic converter.

Checking

1 See Section 4 of Chapter 6.

Removal and refitting

2 Disconnect the battery negative (earth) lead

- see Section 1.

3 Raise the front of the vehicle, and support it

securely on axle stands.

Warning: Do not place any part of

your body under a vehicle when

it’s supported only by a jack!

4 Unplug the sensor’s electrical connector

(see illustration).

9 Crankshaft speed/position

sensor -

checking, removal and refitting

8 Ignition timing - checking

7 Ignition module (automatic

transmission models only) -

removal and refitting

5•4 Engine electrical systems

6.9 Unplug coil electrical connector (A),

suppressor connector (B), and spark

plug/HT leads (C), remove screws (D), then

undo Torx-type screws (E) to release

ignition coil assembly

7.3 Separate ignition module is fitted to

automatic transmission models only - note

electrical connector (A) and retaining

screws (B)

8.3 Service connector (A) mounted on

engine compartment bulkhead is fitted with

“plug-in bridge” (B) to set engine to use

(unleaded) petrol of 95 RON octane rating

9.4 Location of crankshaft speed/position

sensor - connector arrowed - in front of

cylinder block/crankcase