Ford Mondeo (petrol engines). Manual - part 55

the specified mileage (or time) since the last

service has been reached.

4 To reset the service interval system and

turn off the light, a switch inside the glovebox

must be depressed for a minimum of 4

seconds with the ignition switched on. This

should be carried out by a Ford dealer if the

vehicle is still in the warranty period.

Component renewal

5 The following paragraphs describe brief

removal procedures for the auxiliary warning

system components. Disconnect the battery

negative (earth) lead before commencing

work (refer to Chapter 5, Section 1). Refitting

procedures are a reversal of removal.

Display warning bulb

6 Remove the control assembly.

7 Prise off the cover, and pull out the relevant

bulb and bulbholder.

Low air temperature warning sender

unit

8 Remove the front bumper.

9 Unclip the sender unit and disconnect the

multi-plug (see illustration).

Engine oil level sensor

10 Apply the handbrake, jack up the front of

the vehicle and support it on axle stands.

11 Place a container beneath the oil level

sensor, to catch any spilt oil.

12 Unscrew the screws and remove the

cover from the sensor.

13 Disconnect the multi-plug.

14 Unscrew and remove the sensor, and

remove the seal (see illustration).

Door ajar sensor

15 Remove the door lock as described in

Chapter 11, Section 14.

16 Unclip the sensor and disconnect the

multi-plug.

Low coolant warning switch

17 Refer to Chapter 3, Section 6.

Low washer fluid switch

18 Disconnect the multi-plug from the

washer fluid reservoir.

19 Drain or syphon out the fluid from the

reservoir.

20 Using a screwdriver, lever out the switch

from the reservoir (see illustration).

Service indicator reset switch

21 Remove the glove compartment lid as

described in Chapter 11, Section 32.

22 Carefully lever out the switch using a

small screwdriver.

23 Remove the rear cover and disconnect

the wiring (see illustration).

Control assembly

24 Remove the instrument panel surround,

referring to Section 10.

25 Unscrew the mounting screws,

disconnect the multi-plugs and remove the

assembly.

Bulb failure module

26 Remove the lower facia panel from under

the steering wheel.

27 Unclip the bulb failure module and

disconnect the multi-plug.

Note: From November 1993, for added

security, a complex Bosch immobiliser system

was fitted to some models. For further details,

refer to your Ford dealer.

1 All UK models are fitted with an anti-theft

alarm system, incorporating movement

sensors and an ignition immobiliser. The

system is activated when the vehicle is

locked.

2 The system includes a start inhibitor circuit,

which makes it impossible to start the engine

with the system armed.

3 The movement sensors consist of two

ultrasonic units, located in the “B” pillars,

incorporating transmitters and receivers (see

illustrations). The receivers check that the

echo frequency matches the original

frequency. If there is any significant

difference, the system triggers the alarm.

20 Anti-theft alarm system - general

information

12•18 Body electrical system

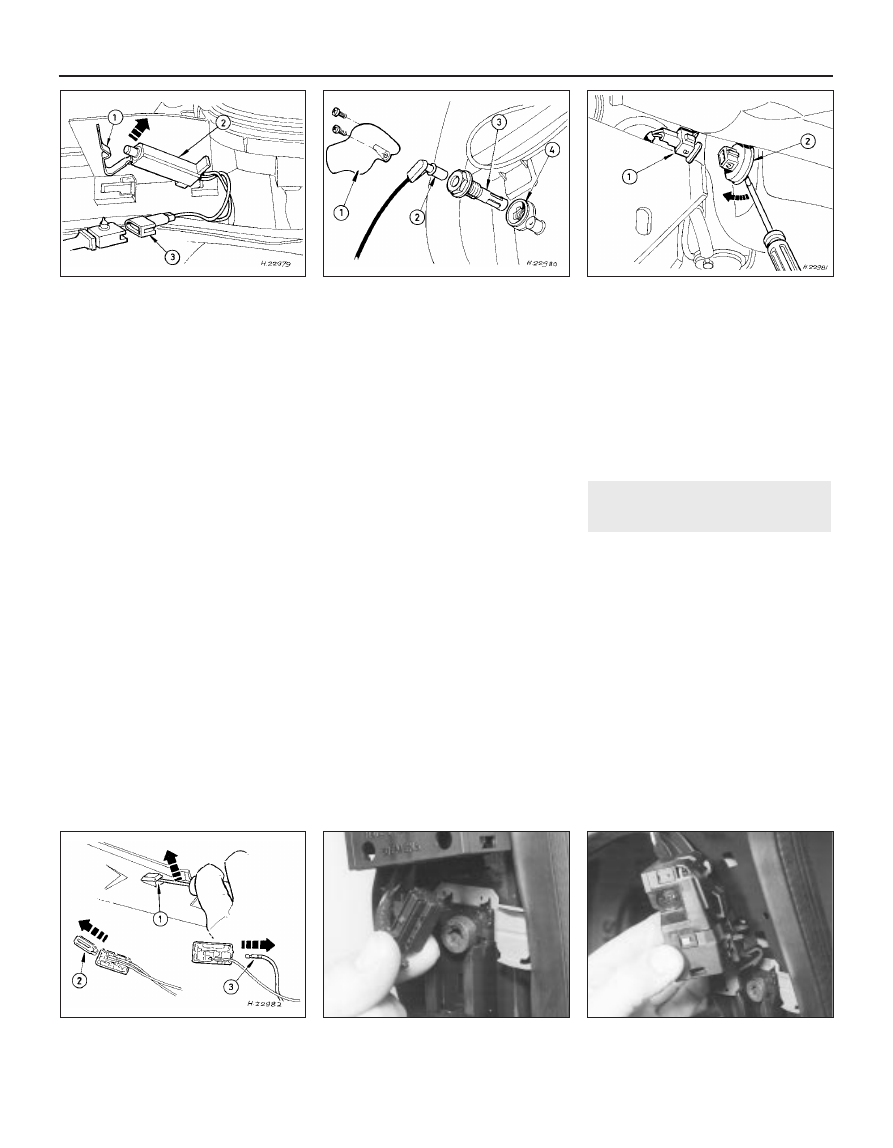

19.9 Low air temperature sender unit

removal

1 Clip 2 Sender unit 3 Multi-plug

19.14 Engine oil level sensor removal

1 Cover 2 Multi-plug 3 Sensor 4 Seal

19.20 Removing the low washer fluid

switch

19.23 Service indicator switch removal

1 Lever out the switch 2 Cover 3 Wiring

20.3A Disconnecting a movement sensor

multi-plug

20.3B Removing a movement sensor