Ford Mondeo (petrol engines). Manual - part 33

and remove the clevis pin securing the servo

unit pushrod to the pedal cross-link arm.

7 On left-hand drive models, unscrew the nut

securing the pedal trunnion to the servo unit

pushrod inside the passenger compartment.

The nut is located near the top of the pedal,

and is accessible through an access hole. For

improved access, remove the lower facia

panel first.

8 Withdraw the servo unit from the bulkhead,

and remove it from the engine compartment.

On left-hand drive models, take care not to

damage the bulkhead rubber grommet as the

pushrod passes through it.

9 Note that the servo unit cannot be

dismantled for repair or overhaul and, if faulty,

must be renewed.

Refitting

10 Refitting is a reversal of the removal

procedure. Refer to Section 11 for details of

refitting the master cylinder.

Removal

1 Depress the brake pedal four or five times,

to dissipate any remaining vacuum from the

servo unit.

2 Disconnect the vacuum hose adaptor at the

servo unit, by pulling it free from the rubber

grommet (see illustration). If it is reluctant to

move, prise it free, using a screwdriver with its

blade inserted under the flange.

3 Detach the vacuum hose from the inlet

manifold connection, pressing in the collar to

disengage the tabs, then withdrawing the

collar slowly.

4 If the hose or the fixings are damaged or in

poor condition, they must be renewed.

Testing

5 Examine the non-return valve for damage

and signs of deterioration, and renew it if

necessary. The valve may be tested by

blowing through its connecting hoses in both

directions. It should only be possible to blow

from the servo end towards the inlet manifold.

Refitting

6 Refitting is a reversal of the removal

procedure. If fitting a new non-return valve,

ensure that it is fitted the correct way round.

Removal

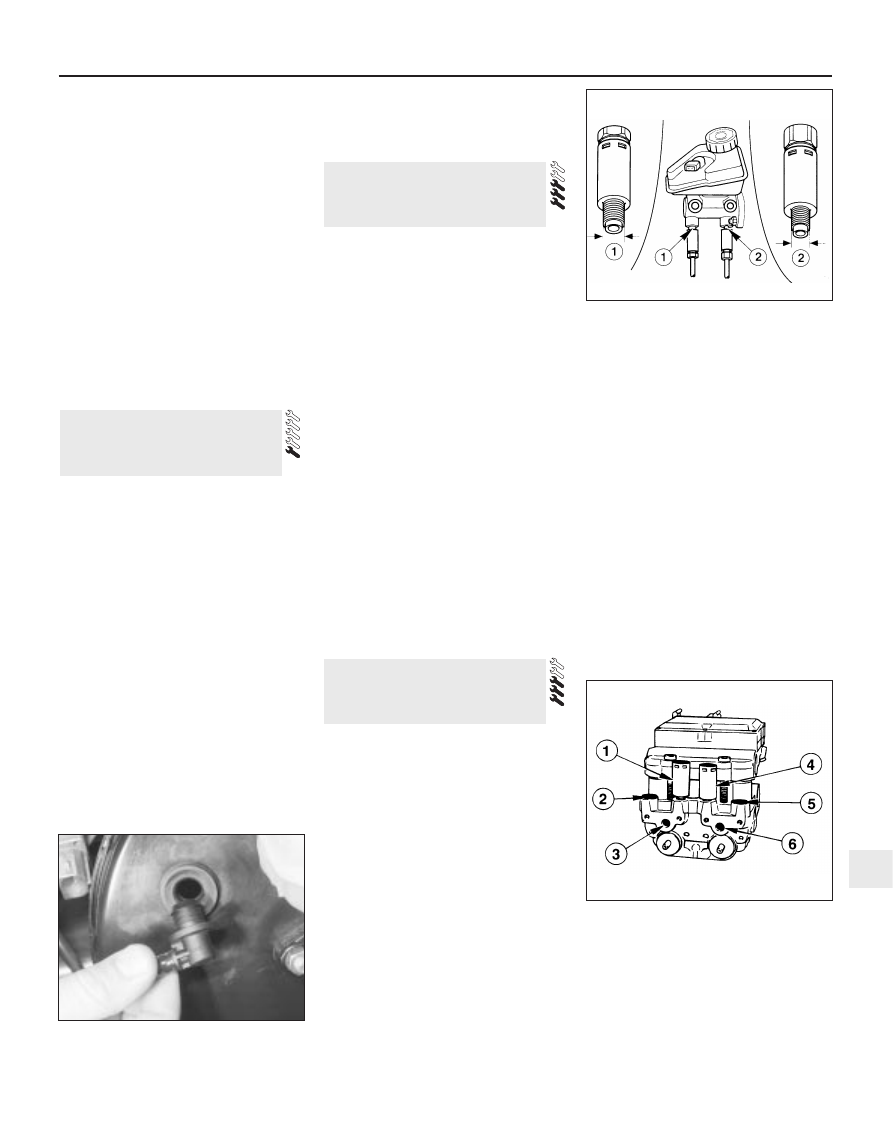

1 On non-ABS models, the two pressure-

control relief valves (sometimes referred to as

pressure-conscious reducing valves) are

located on the master cylinder outlets to the

rear brake line circuits.

2 Unscrew and remove the fluid reservoir filler

cap, and draw off the fluid - see Section 11.

3 Position some rags beneath the master

cylinder, to catch any spilled fluid.

4 Clean around the valve to be removed.

Hold the PCR valve stationary with one

spanner, and unscrew the hydraulic pipe

union nut with another spanner. Pull out the

pipe, and bend it slightly away from the valve.

5 Unscrew the PCR valve from the master

cylinder.

6 Note that the primary and secondary PCR

valves have different thread diameters, to

prevent incorrect fitment. The primary valve

has a 12 mm diameter thread, and the

secondary valve has a 10 mm diameter thread

(see illustration).

Refitting

7 Refitting is a reversal of the removal

procedure. On completion, bleed the

hydraulic system as described in Section 15.

Removal

1 On ABS models, the pressure-control relief

valves are located on the ABS hydraulic unit

(see illustration).

2 Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

3 Remove the air cleaner assembly as

described in Chapter 4.

4 Remove the engine air inlet duct and air

plenum chamber.

5 Disconnect the low fluid level warning

multi-plug from the brake fluid reservoir.

6 Unscrew and remove the brake fluid

reservoir filler cap, and completely seal the

top of the reservoir using cling film or

adhesive tape. This will reduce loss of fluid

when the PCR valve is removed.

7 Unscrew the master cylinder mounting

nuts, and carefully withdraw the cylinder from

the servo unit, leaving the brake pipes still

connected to it. Move the master cylinder

over to the left-hand side of the engine

compartment, to rest against the left-hand

suspension turret. (Throughout this manual,

left- and right-hand are as seen from the

driver’s seat.)

8 Unscrew the servo unit mounting nuts, and

move the unit to one side.

9 Position some rags beneath the ABS unit,

to catch spilled fluid.

10 Clean around the valve to be removed.

Hold the PCR valve stationary with one

spanner, and unscrew the hydraulic pipe

union nut with another spanner. Pull out the

pipe, and bend it slightly away from the valve.

11 Unscrew the PCR valve from the ABS

unit.

Refitting

12 Refitting is a reversal of the removal

procedure. On completion, bleed the

hydraulic system as described in Section 15.

19 Pressure-control relief valve

(ABS models) -

removal and refitting

18 Pressure-control relief valve

(non-ABS models) -

removal and refitting

17 Vacuum servo unit vacuum

hose and non-return valve -

removal, testing and refitting

Braking system 9•13

9

17.2 Removing the plastic adaptor from

the servo unit

18.6 Pressure-control relief valve

locations

1 Primary PCR valve (12 mm)

2 Secondary PCR valve (10 mm)

19.1 Pressure-control relief valve locations

on the ABS hydraulic unit

1 PCR valve, rear right brake circuit

2 Outlet, front left brake circuit

3 Inlet, from brake master cylinder secondary

circuit

4 PCR valve, rear left brake circuit

5 Outlet, front right brake circuit

6 Inlet, from brake master cylinder primary

circuit