Ford Mondeo (petrol engines). Manual - part 22

make sure that no dirt or oil was between the

bearing shells and the caps or block when the

clearance was measured. If the Plastigage is

noticeably wider at one end than the other,

the journal may be tapered (see Section 13).

12 Carefully scrape all traces of the

Plastigage material off the main bearing

journals and the bearing surfaces. Be very

careful not to scratch the bearing - use your

fingernail or the edge of a credit card.

Final refitting

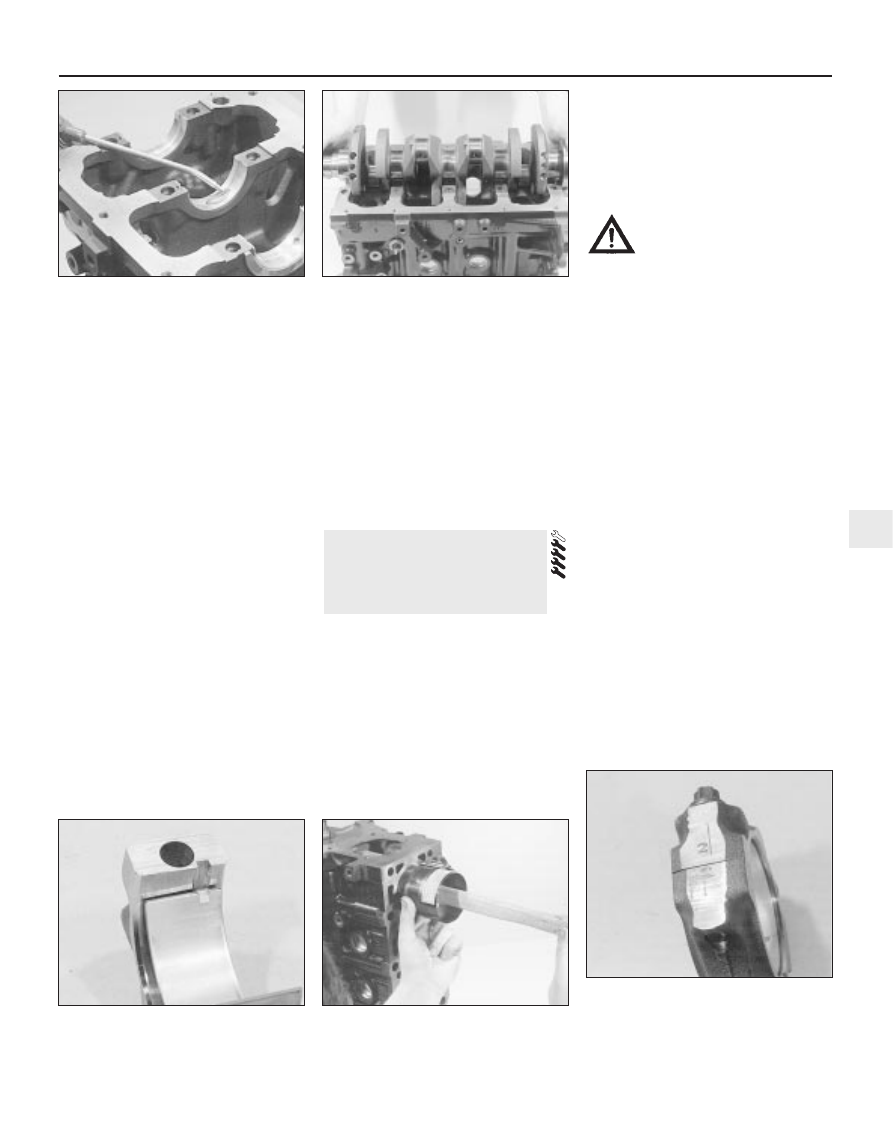

13 Carefully lift the crankshaft out of the

engine. Clean the bearing surfaces of the

shells in the block, then apply a thin, uniform

layer of clean molybdenum disulphide-based

grease, engine assembly lubricant, or clean

engine oil to each surface (see illustration).

Coat the thrustwasher surfaces as well.

14 Lubricate the crankshaft oil seal journals

with molybdenum disulphide-based grease,

engine assembly lubricant, or clean engine oil.

15 Make sure the crankshaft journals are

clean, then lay the crankshaft back in place in

the block (see illustration). Clean the bearing

surfaces of the shells in the caps, then

lubricate them. Install the caps in their

respective positions, with the arrows pointing

to the timing belt end of the engine.

16 Working on one cap at a time, from the

centre main bearing outwards (and ensuring

that each cap is tightened down squarely and

evenly onto the block), tighten the main

bearing cap bolts to the specified torque

wrench setting.

17 Rotate the crankshaft a number of times

by hand, to check for any obvious binding.

18 Check the crankshaft endfloat (see

Section 10). It should be correct if the

crankshaft thrust faces aren’t worn or

damaged, and if the No 3 (centre) main

bearing’s upper shell has been renewed.

19 Refit the crankshaft left-hand oil seal

carrier, and install a new seal (see Part A of

this Chapter, Section 20).

1 Before refitting the piston/connecting rod

assemblies, the cylinder bores must be

perfectly clean, the top edge of each cylinder

must be chamfered, and the crankshaft must

be in place.

2 Remove the big-end bearing cap from No 1

cylinder connecting rod (refer to the marks

noted or made on removal). Remove the

original bearing shells, and wipe the bearing

recesses of the connecting rod and cap with a

clean, lint-free cloth. They must be kept

spotlessly-clean!

Big-end bearing running

clearance check

3 Clean the back of the new upper bearing

shell, fit it to the connecting rod, then fit the

other shell of the bearing set to the big-end

bearing cap. Make sure the tab on each shell

fits into the notch in the rod or cap recess

(see illustration).

Caution: Don’t hammer the shells

into place, and don’t nick or

gouge the bearing face. Don’t

lubricate the bearing at this time.

4 It’s critically important that all mating

surfaces of the bearing components are

perfectly clean and oil-free when they’re

assembled.

5 Position the piston ring gaps as described

in Section 16, lubricate the piston and rings

with clean engine oil, and attach a piston ring

compressor to the piston. Leave the skirt

protruding about a quarter-inch, to guide the

piston into the cylinder bore. The rings must

be compressed until they’re flush with the

piston.

6 Rotate the crankshaft until No 1 crankpin

(big-end) journal is at BDC (Bottom Dead

Centre), and apply a coat of engine oil to the

cylinder walls.

7 Arrange the No 1 piston/connecting rod

assembly so that the arrow on the piston

crown points to the timing belt end of the

engine. The cylinder number (counting from

the timing belt end of the engine) is etched

into the flat-machined surface of the

connecting rod and its cap, and must be

visible from the front (exhaust side) of the

engine (see illustrations 9.5A and 9.5B).

Gently insert the assembly into the No 1

cylinder bore, and rest the bottom edge of the

ring compressor on the engine block.

8 Tap the top edge of the ring compressor to

make sure it’s contacting the block around its

entire circumference.

9 Gently tap on the top of the piston with the

end of a wooden hammer handle (see

illustration), while guiding the connecting

18 Piston/connecting rod

assemblies -

refitting and big-end bearing

running clearance check

Engine removal and general engine overhaul procedures 2B•21

2B

18.3 Tab on each big-end bearing shell

must engage with notch in connecting rod

or cap

18.9 The piston can be driven gently into

the cylinder bore with the end of a wooden

or plastic hammer handle

18.11 The connecting rod and big-end

bearing cap of each assembly must share

the same etched cylinder number, visible

from the same (front/exhaust) side of the

engine

17.13 Ensure bearing shells are absolutely

clean, lubricate liberally . . .

17.15 . . . and refit the crankshaft