Ford Mondeo (petrol engines). Manual - part 12

throttle linkage as described in Chapter 4.

Where fitted, disconnect also the cruise

control actuator cable (see Chapter 12).

3 Remove the timing belt upper cover (see

Section 9).

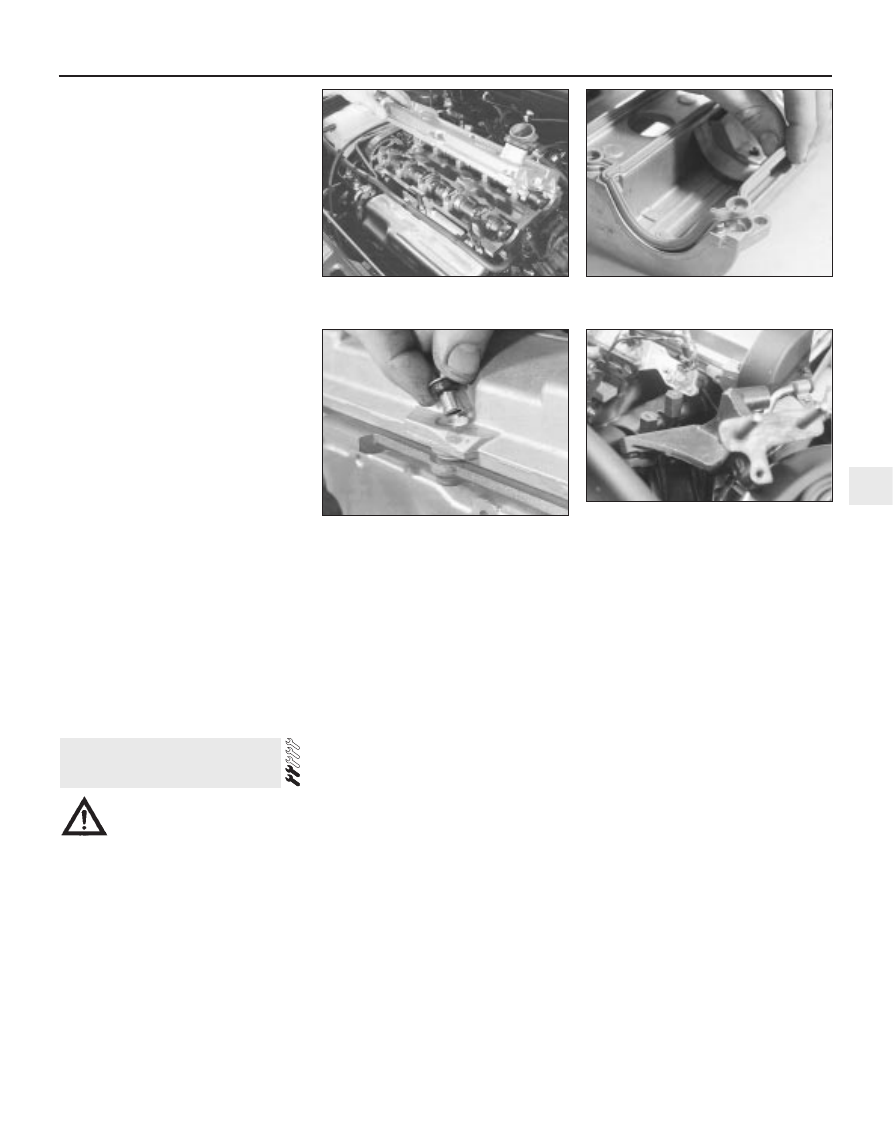

4 Disconnect the crankcase breather hose

from the cylinder head cover union (see

illustration).

5 Unplug the HT leads from the spark plugs

and withdraw them, unclipping the leads from

the cover.

6 Working progressively, unscrew the

cylinder head cover retaining bolts, noting the

spacer sleeve and rubber seal at each, then

withdraw the cover (see illustration).

7 Discard the cover gasket; this must be

renewed whenever it is disturbed. Check that

the sealing faces are undamaged, and that

the rubber seal at each retaining bolt is

serviceable; renew any worn or damaged

seals.

8 On refitting, clean the cover and cylinder

head gasket faces carefully, then fit a new

gasket to the cover, ensuring that it locates

correctly in the cover grooves (see

illustration).

9 Refit the cover to the cylinder head, then

insert the rubber seal and spacer sleeve at

each bolt location (see illustration). Start all

bolts finger-tight, ensuring that the gasket

remains seated in its groove.

10 Working in a diagonal sequence from the

centre outwards, and in two stages (see

Specifications), tighten the cover bolts to the

specified torque wrench setting.

11 Refit the HT leads, clipping them into

place so that they are correctly routed; each

is numbered, and can also be identified by

the numbering on its respective coil terminal.

12 Reconnect the crankcase breather hose,

and refit the timing belt upper cover.

Reconnect and adjust the accelerator cable,

then refit the air cleaner assembly cover with

the air mass meter, the resonator and the

plenum chamber (see Chapter 4).

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system. Don’t smoke,

or allow naked flames or bare light bulbs in

or near the work area. Don’t work in a

garage where a natural gas appliance

(such as a clothes dryer or water heater) is

installed. If you spill petrol on your skin,

rinse it off immediately. Have a fire

extinguisher rated for petrol fires handy,

and know how to use it.

Removal

1 Park the vehicle on firm, level ground,

apply the handbrake firmly, and slacken the

nuts securing the right-hand front roadwheel.

2 Relieve the fuel system pressure (see

Chapter 4).

3 Disconnect the battery negative (earth) lead

- see Chapter 5, Section 1.

4 Unplugging the two electrical connectors

and disconnecting the vacuum hose (where

fitted), remove the air cleaner assembly cover

with the air mass meter, the resonator and the

plenum chamber (see Chapter 4).

5 Disconnect the accelerator cable from the

throttle linkage as described in Chapter 4 -

where fitted, disconnect also the cruise

control actuator cable (see Chapter 12).

6 Disconnect the crankcase breather hose

from the cylinder head cover union.

7 Unbolt the upper part of the exhaust

manifold heat shield; unclip the coolant hose

to allow it to be withdrawn. Slacken the

sleeve nut securing the EGR pipe to the

manifold, remove the two screws securing

the pipe to the ignition coil bracket, then

unscrew the sleeve nut securing the pipe to

the EGR valve - see Chapter 6 for full details if

required.

8 Remove the two screws securing the wiring

“rail” to the top of the manifold - this is simply

so that it can be moved as required to reach

the manifold bolts. Unplug their electrical

connectors to disconnect the camshaft

position sensor and the coolant temperature

sensor, then unclip the wiring from the ignition

coil bracket, and secure it to the manifold.

9 Remove the three screws securing the

wiring “rail” to the rear of the manifold.

Releasing its wire clip, unplug the large

electrical connector (next to the fuel pressure

regulator) to disconnect the wiring of the

manifold components from the engine wiring

loom.

10 Marking or labelling them as they are

unplugged, disconnect the vacuum hoses as

follows:

(a) One from the rear of the throttle housing

(only the one hose - there is no need to

disconnect the second hose running to

the fuel pressure regulator).

(b) One from the union on the manifold’s left-

hand end.

(c) The braking system vacuum servo unit

hose (see Chapter 9 for details).

(d) One from the Exhaust Gas Recirculation

(EGR) valve.

11 Equalise the pressure in the fuel tank by

removing the filler cap, then undo the fuel

feed and return lines connecting the engine to

the chassis (see Chapter 4). Plug or cap all

open fittings.

12 Unbolt the power steering high-pressure

pipe and the earth lead from the cylinder

head rear support plate/engine lifting eye,

then unscrew the bolt securing the support

plate/lifting eye to the alternator mounting

bracket.

13 Unscrew the six nuts securing the

engine/transmission right-hand mounting

bracket, then withdraw the bracket.

14 Remove the alternator (see Chapter 5).

15 Unbolt the alternator mounting bracket

from the rear of the cylinder block and

withdraw it, together with the cylinder head

rear support plate/engine lifting eye (see

illustration).

6 Inlet manifold -

removal and refitting

In-car engine repair procedures 2A•7

2A

5.8 Ensure gasket is located correctly in

cover groove

5.6 Removing cylinder head cover

5.9 Ensure rubber seal is fitted to each

cover bolt spacer, as shown

6.15 Alternator mounting bracket must be

unbolted from rear of cylinder block to

permit access to inlet manifold nut