Ford F150 Pickup. Manual - part 694

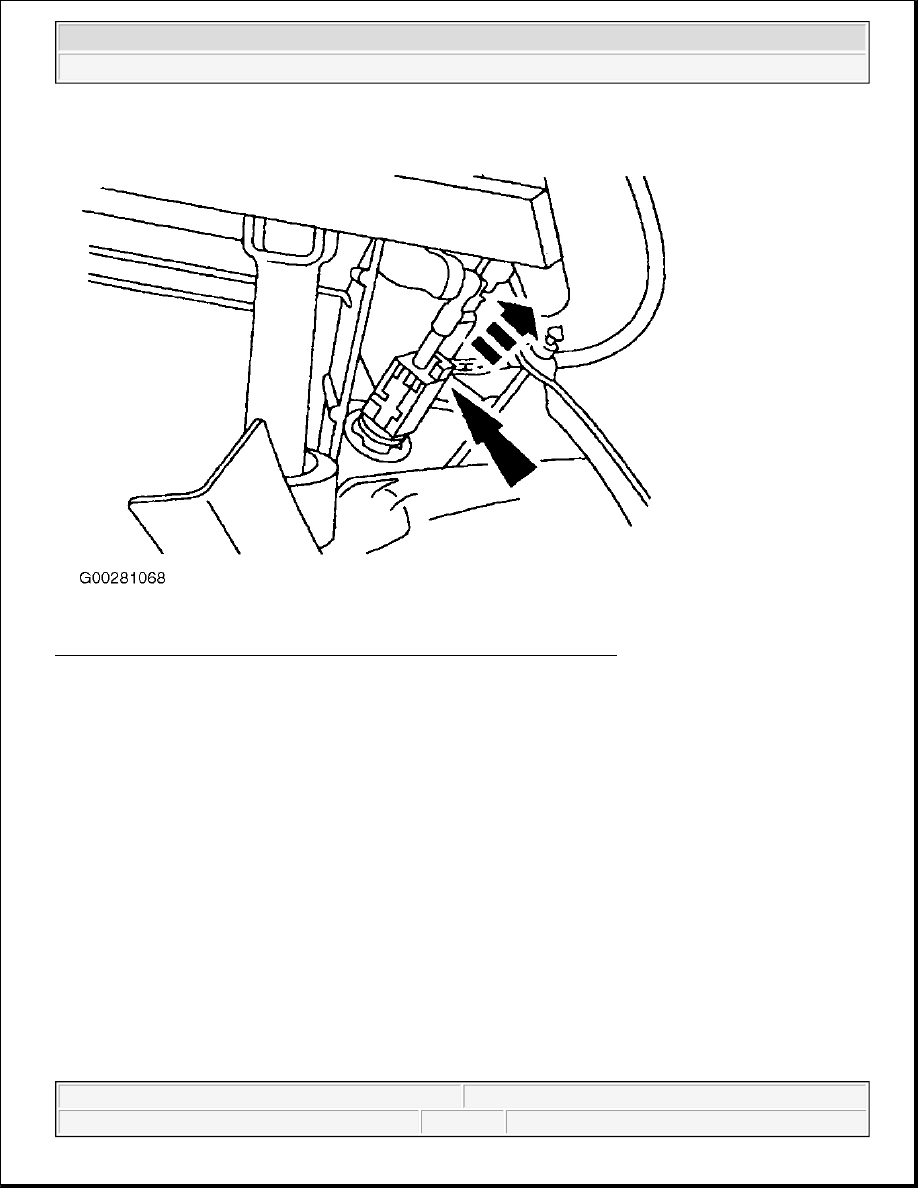

Fig. 13: Disconnecting Clutch Pedal Position Switch Electrical Connector

Courtesy of FORD MOTOR CO.

2003 Ford Pickup F150

2003 STARTING & CHARGING SYSTEMS Starters - F150 Pickup

|

|

|

Fig. 13: Disconnecting Clutch Pedal Position Switch Electrical Connector

2003 Ford Pickup F150 2003 STARTING & CHARGING SYSTEMS Starters - F150 Pickup

|