Ford Fiesta (1989-1995). Manual - part 9

8 Fit a new oil filter into position on

the oil pump body, as described in Chap-

ter 1.

9 Lower the vehicle to the ground, and top-

up the engine oil as described in “Weekly

Checks”.

13 Oil pump - dismantling,

inspection and reassembly

3

Dismantling

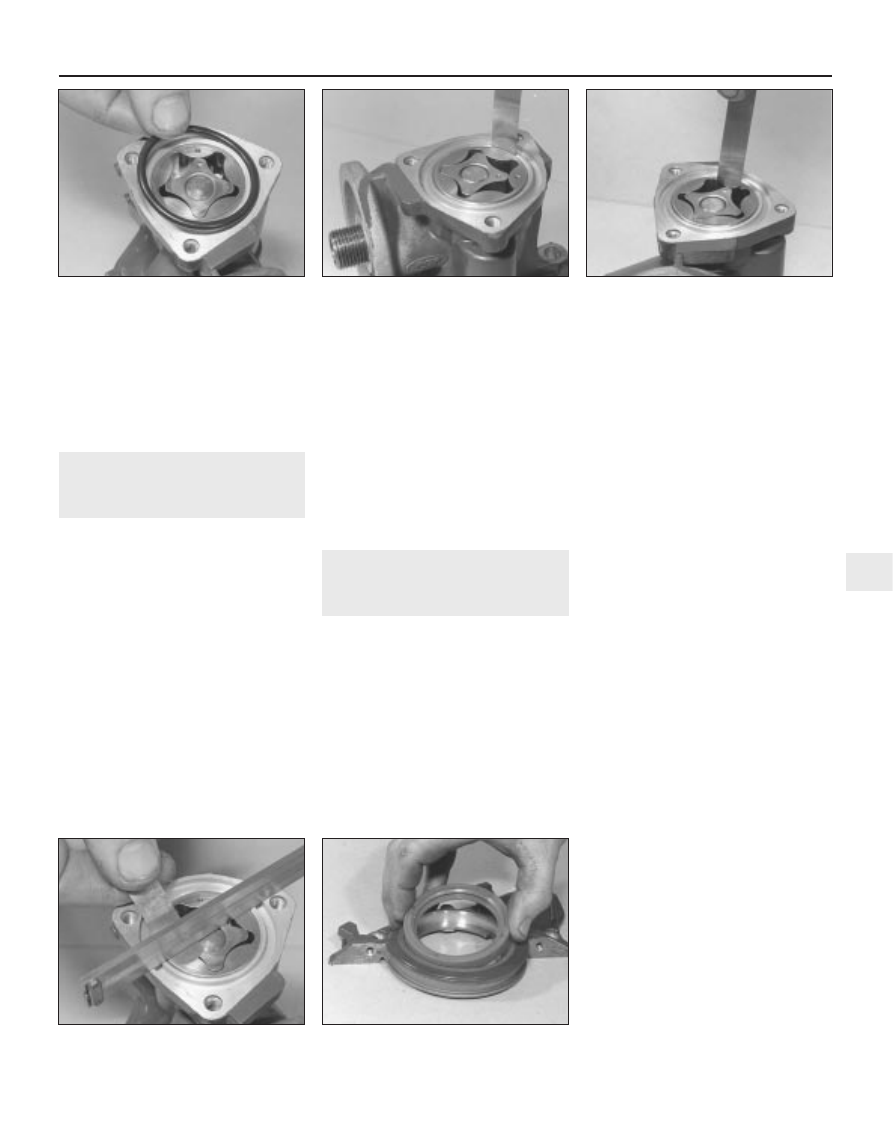

1 To inspect the oil pump components for

excessive wear, undo the retaining bolts and

remove the cover plate from the pump body.

Remove the O-ring seal from the cover face

(see illustration).

2 Wipe the exterior of the pump housing

clean housing.

Inspection

3 Noting their orientation, extract and clean

the rotors and the inner body of the pump

housing. Inspect them for signs of severe

scoring or excessive wear, which if evident

will necessitate renewal of the complete

pump.

4 Using feeler gauges, check the clearances

between the pump body and the outer rotor,

the inner-to-outer rotor clearance, and the

amount of rotor endfloat (see illustrations).

5 Check the drivegear for signs of excessive

wear or damage.

6 If the clearances measured are outside the

specified maximum clearances and/or the

drivegear is in poor condition, the complete

pump unit must be renewed.

Reassembly

7 Refit the rotors into the pump (in their

original orientation), lubricate the rotors and

the new O-ring seal with clean engine oil, and

refit the cover. Tighten the retaining bolts to

the specified torque wrench setting.

14 Crankshaft oil seals -

renewal

3

Front oil seal

1 Remove the crankshaft pulley as described

in Section 8.

2 Using a suitable claw tool, extract the oil

seal from the timing chain cover, but take care

not to damage the seal housing. As it is

removed, note the fitted orientation of the seal

in the cover.

3 Clean the oil seal housing in the timing

chain cover. Lubricate the sealing lips of the

new seal and the crankshaft stub with clean

engine oil.

4 Locate the new seal into position so that it

is squarely located on the crankshaft stub and

in the housing, and is correctly orientated.

Drift it into position using a large socket,

another suitable tool, or the old seal, until the

new seal is flush with the edge of the timing

chain cover.

5 Lightly lubricate the rubbing surface of the

crankshaft pulley, then refit the pulley as

described in Section 8.

Rear oil seal

6 Remove the flywheel as described in

Section 16.

7 Using a suitable claw tool, lever the seal

from the rear seal housing (taking care not to

damage the housing). As it is removed, note

the fitted orientation of the seal.

8 Clean the seal housing, the crankshaft

rear flange face and the flywheel mating

surface.

9 One of two possible methods may be used

to insert the new oil seal, depending on the

tools available.

10 If Ford service tool No 21-011 is available,

lubricate the crankshaft flange and the oil seal

inner lip with clean engine oil. Position the

seal onto the service tool (ensuring correct

orientation), then press the seal into its

housing.

11 If the service tool is not available, remove

the engine sump (Section 11), then unscrew

the Torx-head bolts retaining the rear seal

housing in position, and remove the

seal housing from the rear face of the cylinder

block. New gaskets will be required for both

the seal housing and the sump when refitting.

Clean the seal housing seat and the mating

surfaces of the sump and the crankcase. To fit

the seal squarely into its housing without

damaging either component, place a flat

block of wood across the seal, then carefully

tap the seal into position in the housing (see

illustration). Do not allow the seal to tilt as it

is being fitted. Lubricate the crankshaft flange

and the oil seal inner lip with clean engine oil,

then with a new gasket located on the seal

housing/crankcase face, fit the housing into

position. Take care not damage the seal lips

as it is passed over the crankshaft rear flange

HCS engine in-car repair procedures 2A•9

13.4b Checking the inner rotor-to-outer

rotor clearance

13.4a Checking the outer body-to-rotor

clearance

13.1 Extract the O-ring from the groove in

the oil pump

14.11a Positioning the crankshaft rear oil

seal in its housing

13.4c Checking the rotor endfloat

2A

1595Ford Fiesta Remake