Daewoo Korando. Service manual - part 235

ANTILOCK BRAKE SYSTEM 4F-9

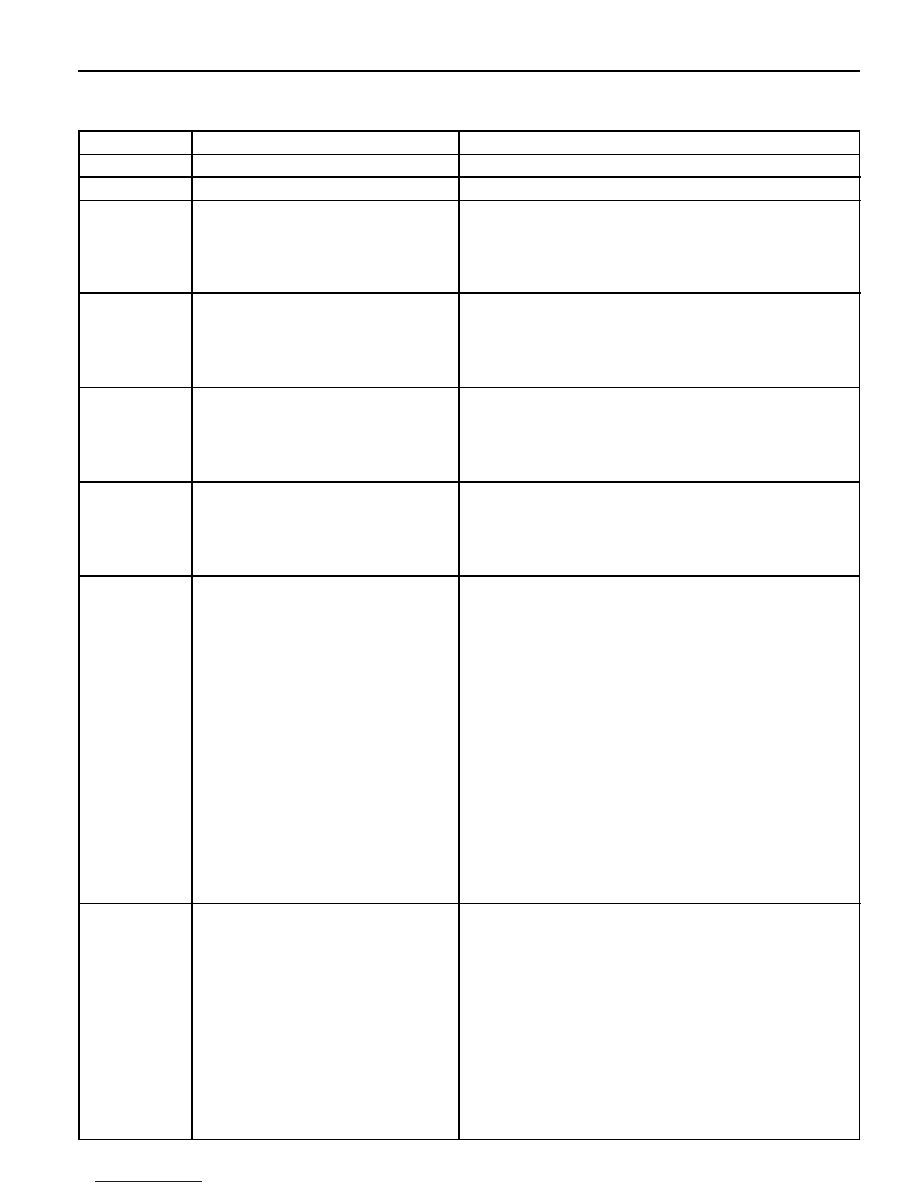

DEFECT CODES

Description

-

Replace the ECU

l

Check resistance of the wheel speed sensor : 1.280K

W

- 1.920K

W

l

Check wire for ground and open.

l

Replace the sensor.

l

Check resistance of the wheel speed sensor : 1.280K

W

- 1.920K

W

l

Check wire for ground and open.

l

Replace the sensor.

l

Check resistance of the wheel speed sensor : 1.280K

W

- 1.920K

W

l

Check wire for ground and open.

l

Replace the sensor.

l

Check resistance of the wheel speed sensor : 1.280K

W

- 1.920K

W

l

Check wire for ground and open.

l

Replace the sensor.

l

Check wire for ground and open.

l

Check connection of the wheel speed sensor connec-

tor and ECU side connector.

l

Measure air gap between wheel teeth and wheel speed

sensor and check installation of wheel tooth.

(Standard air gap : 0.35 - 1.60 mm)

l

Check output voltage of the sensor by rotating the

wheel 1/2 - 1 revolution per second and shaking sen-

sor wire.

-

When measured by multi - meter (AC) :

output voltage > 70 mV

-

When measured in oscilloscope :

output voltage

³

120 mV/P-P

l

Replace the sensor.

l

Check wire for ground and open.

l

Check connection of the wheel speed sensor. con-

nector and ECU side connector.

l

Measure the air gap between wheel teeth and wheel

speed sensor and check installation of wheel tooth.

(Standard air gap : 0.35 - 1.60 mm)

l

Check output voltage of the sensor by rotating the

wheel 1/2 - 1 revolution per second and shaking sen-

sor wire.

-

When measured by multi - meter (AC) :

Defect Code

01

02

03

04

05

06

07

08

Application

Normal

Defective ECU

Front/left Wheel Speed

Sensor (Wire)

Front/right Wheel Speed

Sensor (Wire)

Rear/left Wheel Speed

Sensor (Wire)

Rear/right Wheel Speed

Sensor (Wire)

Front/left Wheel Speed

Sensor (Signal)

Front/right Wheel Speed

Sensor (Signal)