Daewoo Korando. Service manual - part 218

FRONT DRIVE AXLE 3A-19

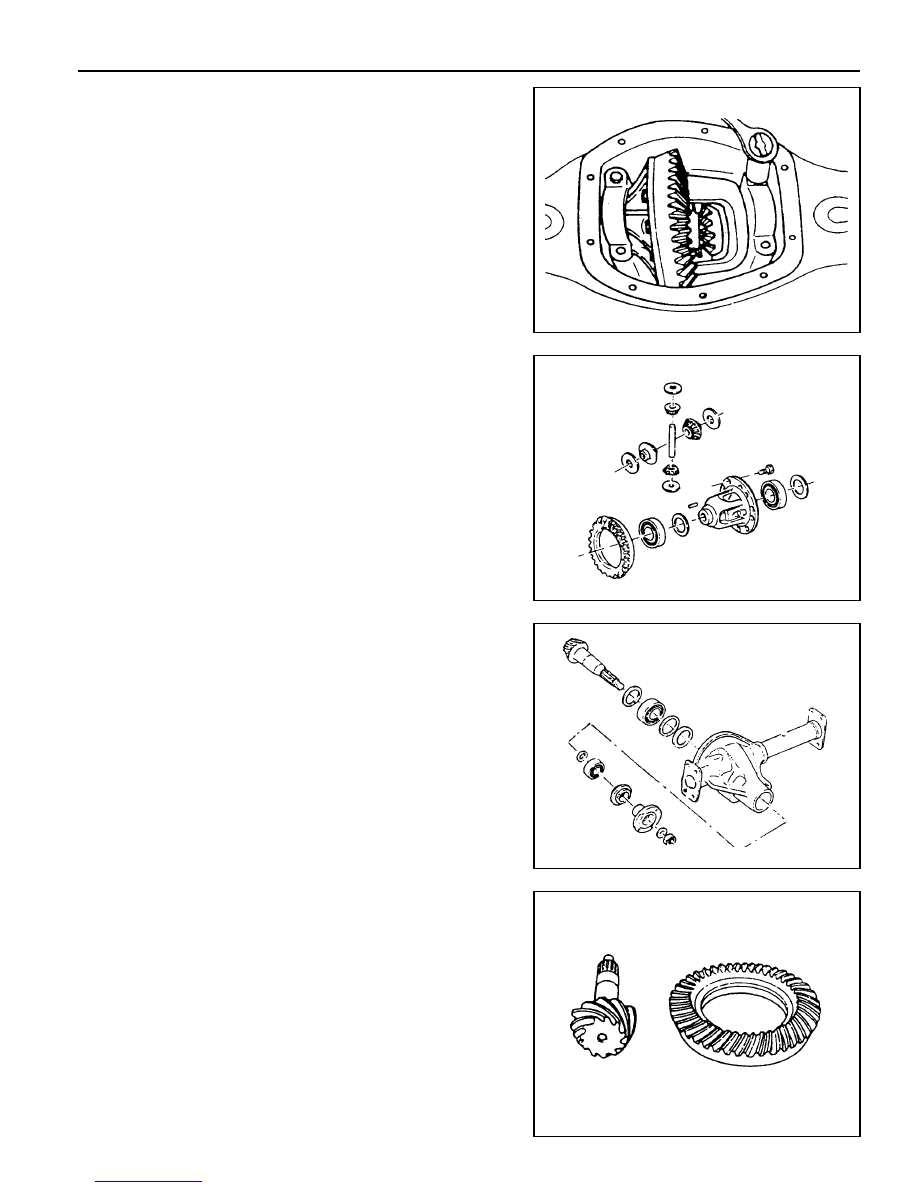

5. Unscrew the bearing cap bolts and remove the bearing caps.

Pull out the differential carrier assembly.

Notice

Place alignment marks on the bearing cap not to change

the caps before removal. When pulling out the differential

carrier assembly, be careful not to damage the axle housing.

6. Disassemble the parts of the differential carrier assembly.

7. Remove the drive pinion lock nut. Disassemble the parts of

the drive pinion.

Assembly Procedure

1. Clean the all parts and check the followings :

l

Check the ring gear and drive pinion for wear and

damage. If damaged, replace it as a set.

l

Check the bearing for sticks, wear, noise and turning

resistance.

l

Check the side gear, pinion, pinion shaft and thrust

washer for wear and damage.

l

Check the differential carrier for crack and wear (bearing

contact surface). Check the gear case for crack.