Daewoo Korando. Service manual - part 173

1F2-56 M161 ENGINE CONTROLS

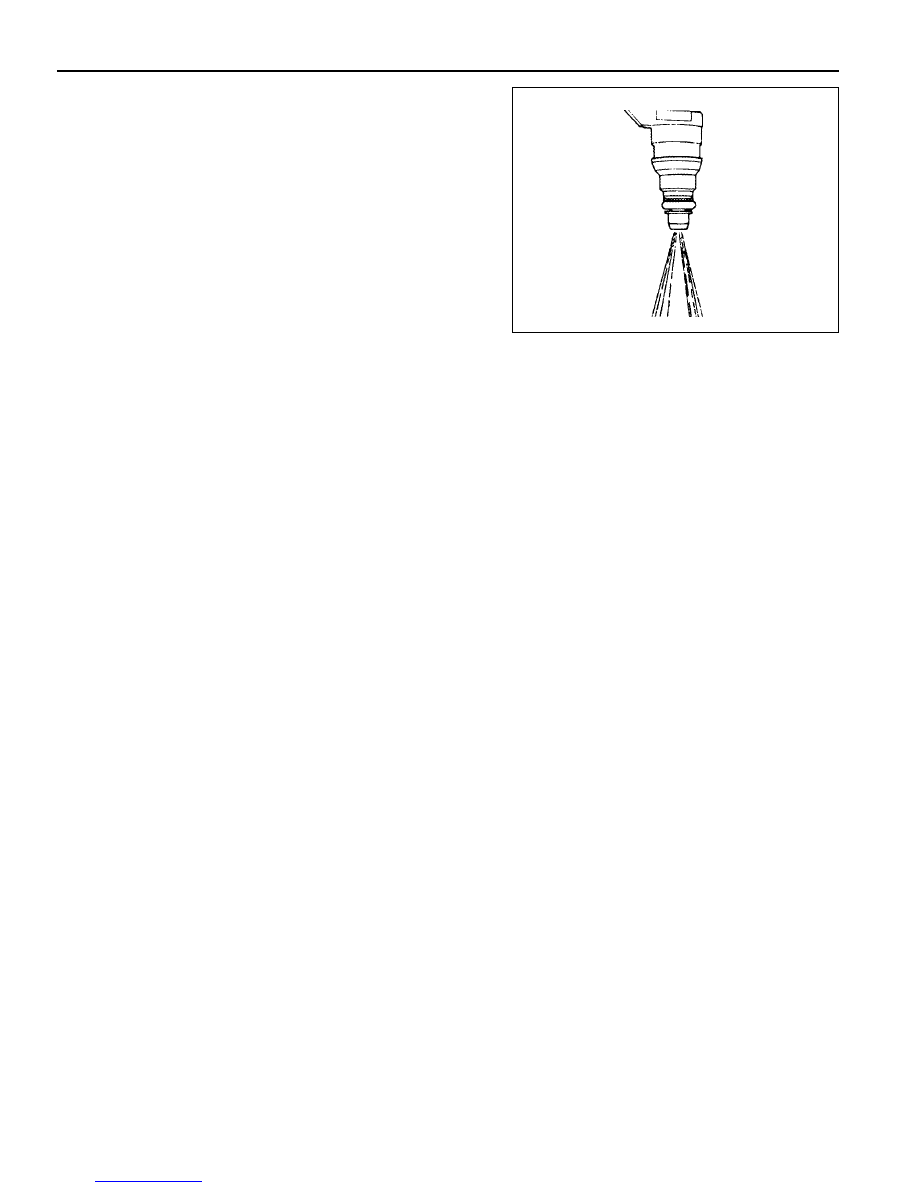

The Injector Spray Pattern Check

1. Connect the test box (129 589 00 21 00) to the ECU.

2. Disconnect the connector from connector.

3. Disconnect the fuel distributor and injector with a unit from

engine without removing the fuel supply and return line.

Notice

Prepare the beaker for taking the poping fuel.

4. Connect either end of shop made cable to the injector.

5. Connect the other end of shop made cable to the No.11

and No.5 terminal of the test box.

6. Turn the ignition switch to "ON" position.

7. Check the injector for normal spray pattern as shown in the

figure. Check injector for leaks or later drops.

Notice

Refer to fuel injector test of engine diagnosis in this section

for detailed information.