Daewoo Korando. Service manual - part 97

1B3-98 OM600 ENGINE MECHANICAL

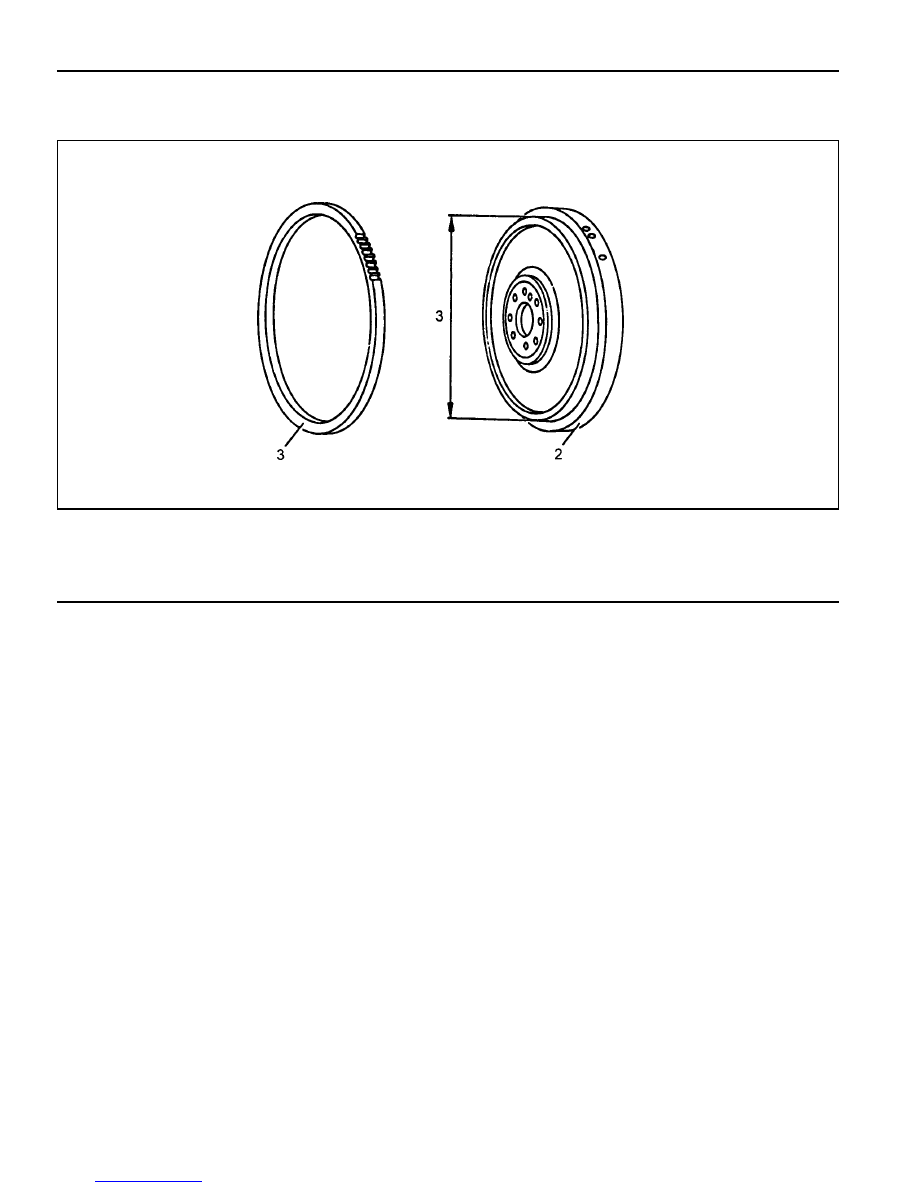

FLYWHEEL RING GEAR

Preceding Work : Removal of flywheel

1 Ring Gear

2 Flywheel

3 Centering Collar Diameter

Tools Required

001 589 53 21 00 Dial Gauge

363 589 02 21 00 Dial Gauge Holder