Daewoo Matiz (2003 year). Service manual - part 156

FIVE-SPEED MANUAL TRANSAXLE 5B – 7

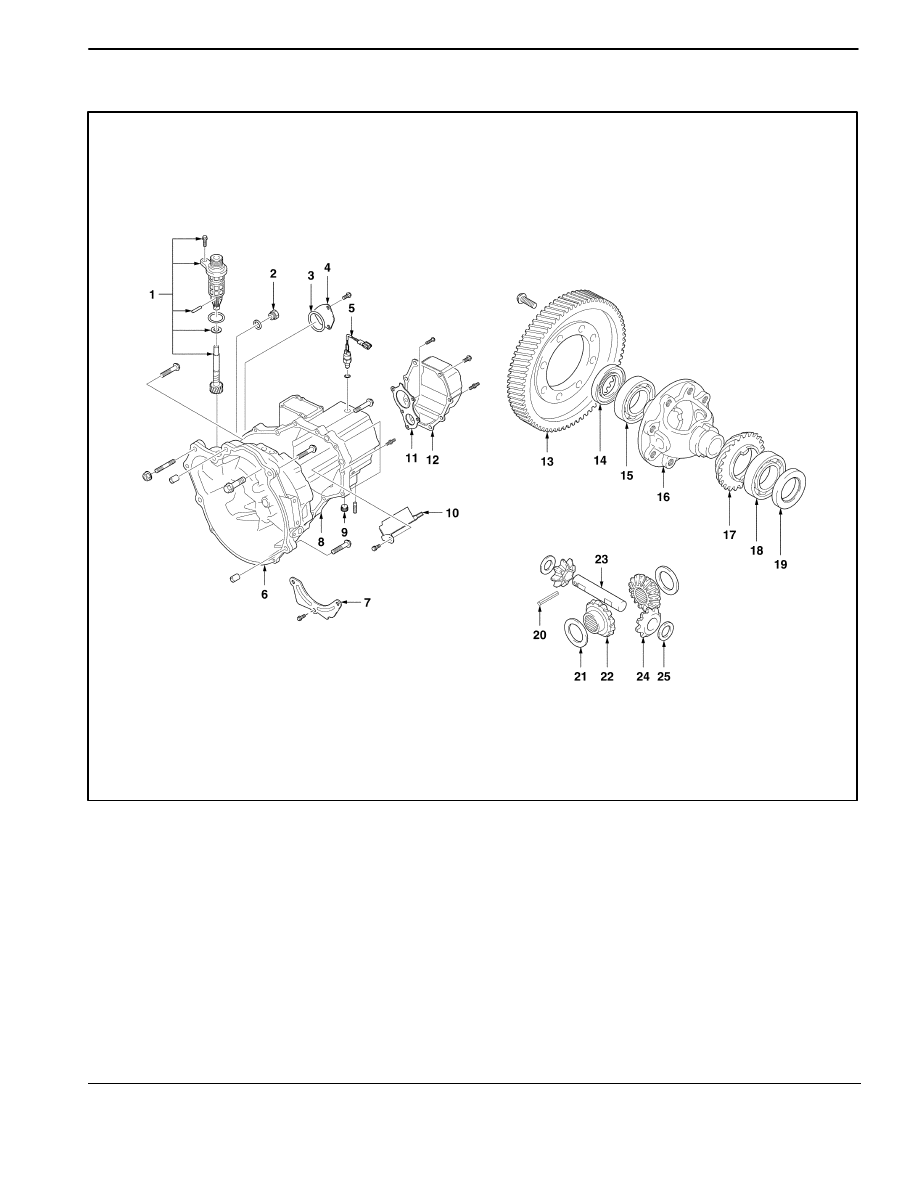

DIFFERENTIAL AND CASE

D13B4041

1 Speedometer Driven Gear

2 Oil Level Plug

3 Case Cap O–ring(Left)

4 Case Cap(Left)

5 Back Up Light Switch

6 Transaxle Case(Right)

7 Oil Plate

8 Transaxle Case(Left)

9 Oil Drain Plug

10 Oil Gutter

11 Side Cover Plate

12 Side Cover

13 Differential Ring Gear

14 Differential Oil Seal(Left)

15 Differential Bearing(Left)

16 Differential Case

17 Speedometer Drive Gear

18 Differential Bearing(Right)

19 Differential Oil Seal(Right)

20 Differential Pinion Gear Shaft Pin

21 Differential Side Gear Adjust Shim

22 Differential Side Gear

23 Differential Pinion Gear Shaft

24 Differential Pinion Gear

25 Differential Pinion Gear Washer