Daewoo Matiz (2003 year). Service manual - part 96

1F – 294 ENGINE CONTROLS

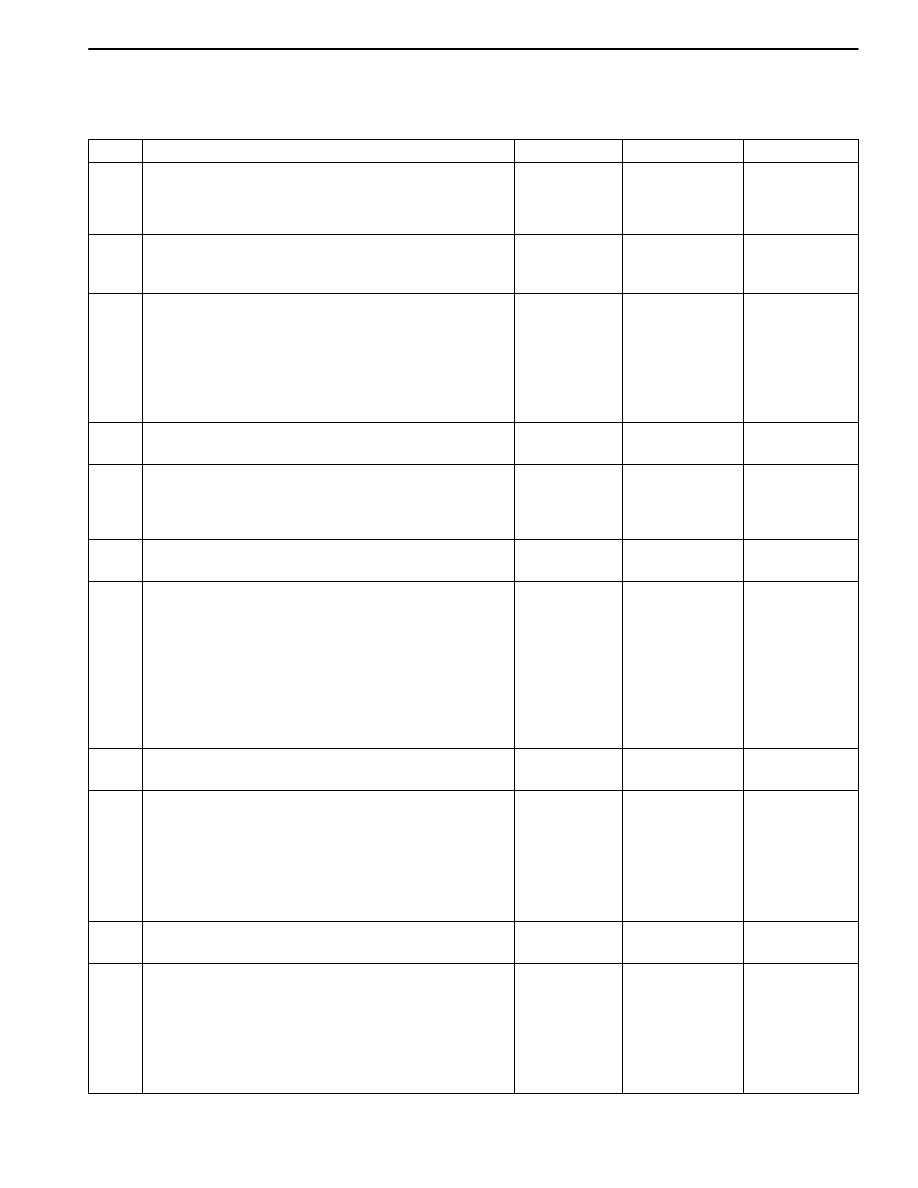

CUTS OUT, MISSES

Definition: Steady pulsation or jerking that follows en-

gine speed, usually more pronounced as engine load in-

creases. The exhaust has a steady spitting sound at idle

or low speed.

Step

Action

Value(s)

Yes

No

1

Were the Important Preliminary Checks performed?

–

Go to Step 2

Go to

“Important

Preliminary

Checks”

2

Check the ignition system voltage output for all of

the cylinders using a spark tester.

Is spark present on all of the cylinders?

–

Go to Step 3

Go to “Ignition

System Check”

3

1. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy

deposits.

2. Check the resistance of the ignition wires.

Replace any ignition wires that have a resistance

greater than the value specified.

Is the problem found?

30000

Ω

Go to Step 4

Go to Step 5

4

Repair or replace any components as needed.

Is the repair complete?

–

System OK

–

5

With the engine running, spray the ignition wires with

a fine water mist to check for arcing and shorting to

ground.

Is the problem found?

–

Go to Step 6

Go to Step 7

6

Replace the ignition wires.

Is the repair complete?

–

System OK

–

7

1. Perform a cylinder compression test.

2. If the compression is low, repair the engine as

needed.

3. Inspect for proper valve timing, bent pushrods,

worn rocker arms, broken or weak valve springs,

and worn camshaft lobes.

4. Inspect the intake manifold and the exhaust

manifold passages for casting flash.

Is the problem found?

–

Go to Step 8

Go to Step 9

8

Repair or replace any components as needed.

Is the repair complete?

–

System OK

–

9

1. Check the fuel system for a plugged in-line fuel

filter.

2. Check the fuel system for low fuel pressure. If the

fuel pressure is below the value specified, service

the fuel system as needed.

3. Inspect for contaminated fuel.

Is the problem found?

380 kPa

(55 psi)

Go to Step 10

Go to Step 11

10

Repair or replace any components as needed.

Is the repair complete?

–

System OK

–

11

1. Disconnect all of the fuel injector harness

connectors at the fuel injectors.

2. Connect an injector test light to the harness

terminals of each fuel injector connector.

3. Note the test light while cranking the engine for

each fuel injector.

Does the test light blink for all of the fuel injectors?

–

Go to Step 13

Go to Step 12