Daewoo Matiz (2003 year). Service manual - part 69

1F – 186 ENGINE CONTROLS

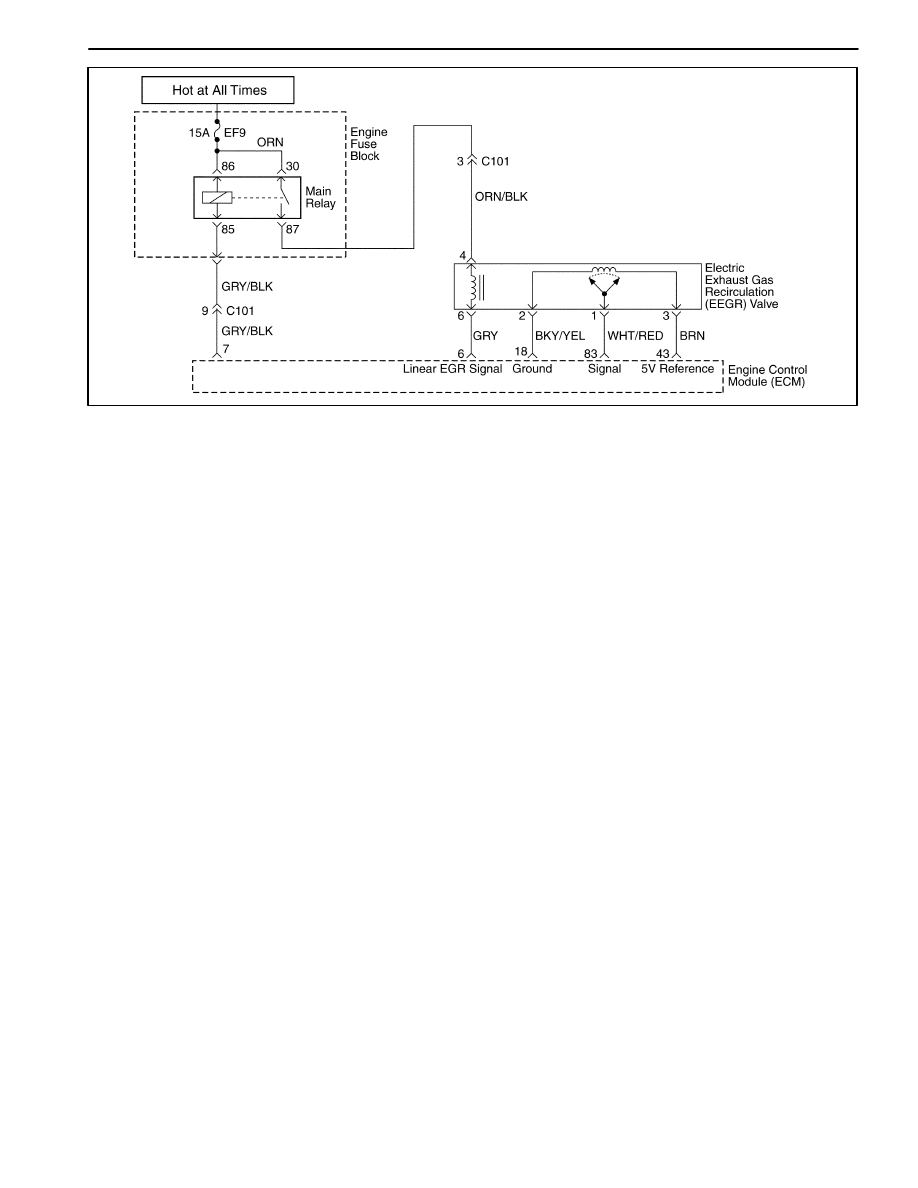

MAA1F230

DIAGNOSTIC TROUBLE CODE (DTC) – P1402 ELECTRIC EXHAUST GAS

RECIRCULATION BLOCKED

Circuit Description

An Electric Exhaust Gas Re-circulation (EEGR) system

is used to lower oxides of nitrogen (NOX) emission lev-

els caused by high combustion temperatures. It a ac-

complishes this by feeding small amounts of exhaust

gases back into the combustion chamber. When the air/

fuel mixture is diluted with the exhaust gases, combus-

tion temperatures are reduced.

A EEGR valve is used on this system. The linear EEGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum.

The valve controls exhaust flow going into the intake

manifold from the exhaust manifold fhrough an orifice

with a engine control module(ECM) controlled pintle.

The ECM controls the pintle position using inputs from

the Throttle Position (TP) and the Manifold Absolute

Pressure (MAP) sensor. The ECM then commands the

EEGR valve to operate when necessary by controlling

an ignition signal through the ECM. This can be moni-

tored on a scan tool as the Desired EEGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EEGR valve, a voltage signal representing

the EEGR valve pintle position is sent to the ECM. This

feedback signal can also be monitored on a scan tool

and is the actual position of the EEGR pintle. The actual

EEGR position should always be near the commanded

or Desired EEGR position.

ThisDiagnostic Trouble Code(DTC) will detect an open

or short circuit.

Conditions for Setting the DTC

D

Engine Coolant Temperature(ECT) is greater than

80

°

C(176

°

F).

D

Intake Air Temperature(IAT) is greater than 15

°

C

(59

°

F).

D

Manifold Absolute Pressure is greater than 75kPA.

D

The EEGR differential rate is less than 3%.

D

Mass Air Flow is between 92 ~157mg/tdc.

D

Engine Speed Is Between 2,500~2,900rpm.

D

DTCs P0107, P0108, P0112, P0113, P0117, P0118,

P0122, P0123, P0131, P0300, P0335, P0336,

P0341, P0342, P1671, P1672, P1673 are NOT SET.

D

EEGR is disabled.

Action Taken When the DTC Sets

D

The Malfunction Indicator Lamp (MIL) will illuminate.

D

The ECM will record operating conditions at the time

the diagnostic fails. This information will be stored in

the Freeze Frame and Failure Records buffers.

D

A history DTC is stored.

Conditions for Clearing the MIL/DTC

D

The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

D

A history DTC will clear after 40 consecutive warm-up

cycles without a fault.

D

DTC(s) can be cleared by using the scan tool.

Diagnostic Aids

Due to moisture associated with exhaust systems, the

EEGR valve may freeze and stick in cold weather at

times. After the vehicle is brought into a warm shop for

repairs, the valve warms and the problem disappears.

By watching the Actual EEGR and desired EEGR posi-

tions on a cold vehicle with a scan tool, the fault can be