Daewoo Nubira. Service manual - part 116

1F – 46

I

ENGINE CONTROLS

DAEWOO V–121 BL4

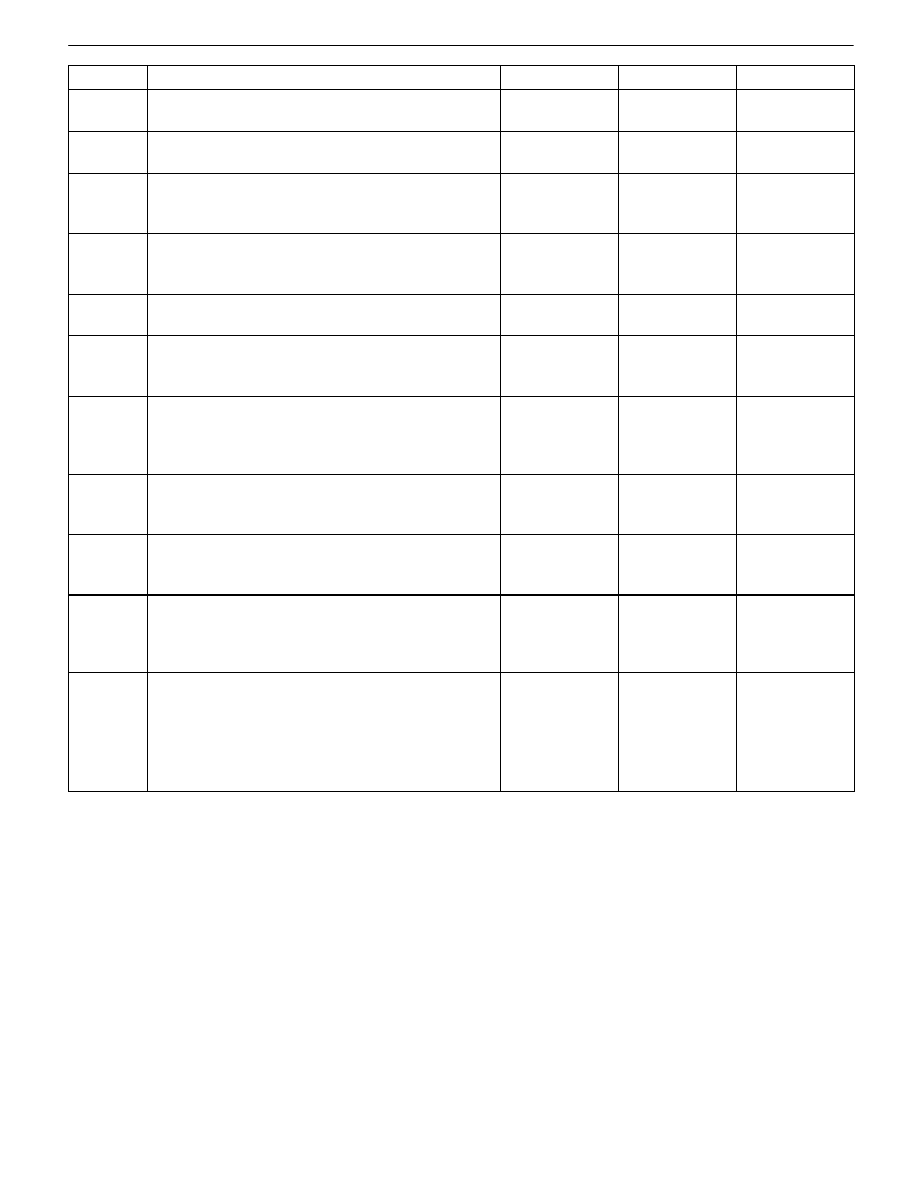

Step

No

Yes

Value(s)

Action

12

Replace the PCM/ECM.

Is the repair complete?

Go to Step 22

13

Repair the short to voltage in the MIL control circuit.

Is the repair complete?

Go to Step 22

14

Check for an open or a poor connection in the MIL

control circuit and repair as necessary.

Is the repair necessary?

Go to Step 22

Go to Step 17

15

With a test light still connected to the ground, probe

the ignition feed terminal F16.

Does the test light illuminate?

Go to Step 18

Go to Step 19

16

Repair the open battery feed circuit.

Is the repair complete?

Go to Step 22

17

Check for an open ignition feed circuit or fuse to the

MIL and repair as necessary.

Is the repair necessary?

Go to Step 22

Go to Step 20

18

Check for a poor connection in the battery feed ter-

minal A4 or the ignition feed terminal F16 and repair

as necessary.

Is the repair necessary?

Go to Step 22

Go to Step 21

19

Repair the open in the ignition feed circuit from termi-

nal F16.

Is the repair complete?

Go to Step 22

20

Replace the instrument panel cluster. Refer to Sec-

tion 9E, Instrumentation/Driver Information.

Is the repair complete?

Go to Step 22

21

Check for a faulty PCM/ECM ground connection at

the engine block or PCM/ECM connector and repair

as necessary.

Is the repair necessary?

Go to Step 22

Go to Step 12

22

1. Allow the engine to idle until normal operating

temperature is reached.

2. Check if any Diagnostic Trouble Codes (DTCs)

are set.

Are any DTCs displayed that have not been diag-

nosed?

Go to the appli-

cable DTC

table

System OK