Lancia DELTA. Instruction - part 13

200

IN AN EMERGENCY

INFLATION PROCEDURE

Put on the protective gloves provided

with the quick tyre repair kit.

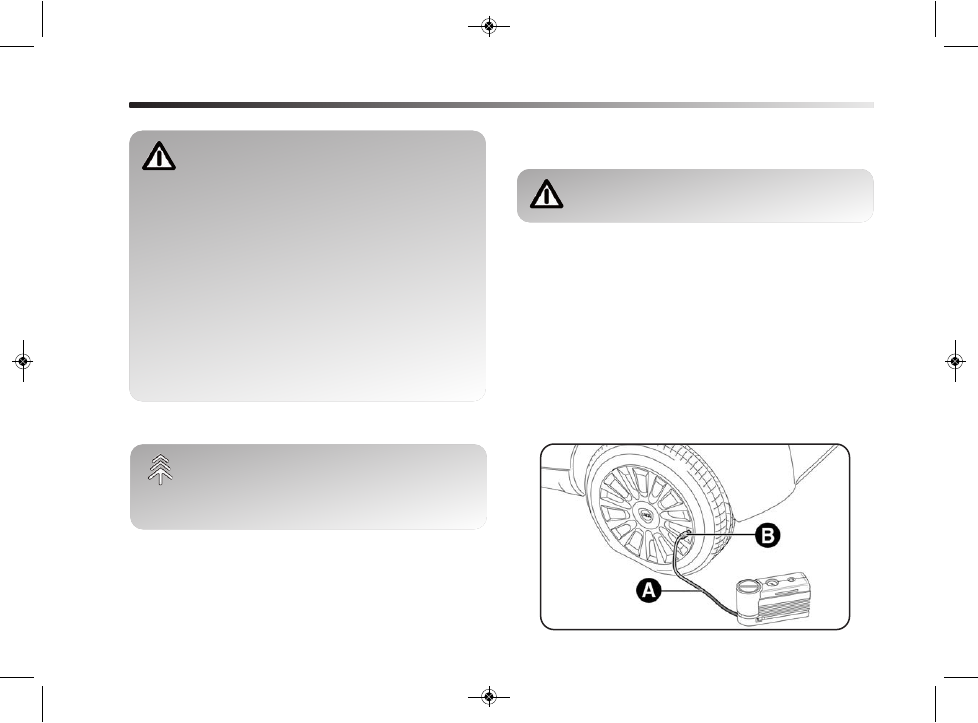

❍ Engage the handbrake. Unscrew the tyre valve cap,

take out the filler hose A - fig. 4 and tighten the ring

nut B on the tyre valve;

fig. 4

L0E0077m

The bottle contains ethylene glycol. It con-

tains latex that might cause allergic reac-

tions. It is harmful if swallowed. It is irri-

tant for the eyes. It may cause sensitisation if in-

haled or on contact. Avoid contact with eyes, skin

and clothes. In the event of contact, wash immedi-

ately with plenty of water. Do not induce vomiting

if swallowed. Rinse your mouth and drink plenty of

water. Call a doctor immediately. Keep out of the

reach of children. The product must not be used by

asthmatics. Do not breathe in the vapours during

insertion and suction. Call a doctor immediately if

allergic reactions are noted. Store the bottle in the

specific compartment, away from sources of heat.

The sealant has an expiry date.

Replace the bottle containing out-of-date

sealant. Dispose of the bottle and the sealant

properly. Dispose of the components in com-

pliance with national and local regulations.

195-232 Delta GB 1ed 03/03/14 09.14 Pagina 200