Lotus Elise / Lotus Exige. Instruction - part 54

Lotus Service Notes Section HG

Page 12

8.

Fit the lower u/j pinch bolt, and tighten to 35 Nm.

9.

Fit the track rod ends into the steering arms, and tighten the nuts to 30 Nm.

10.

Check and adjust the front wheel alignment as detailed in sub-section CI.2.

HG.7 - ADJUSTMENT OF RACK BAR THRUST PAD

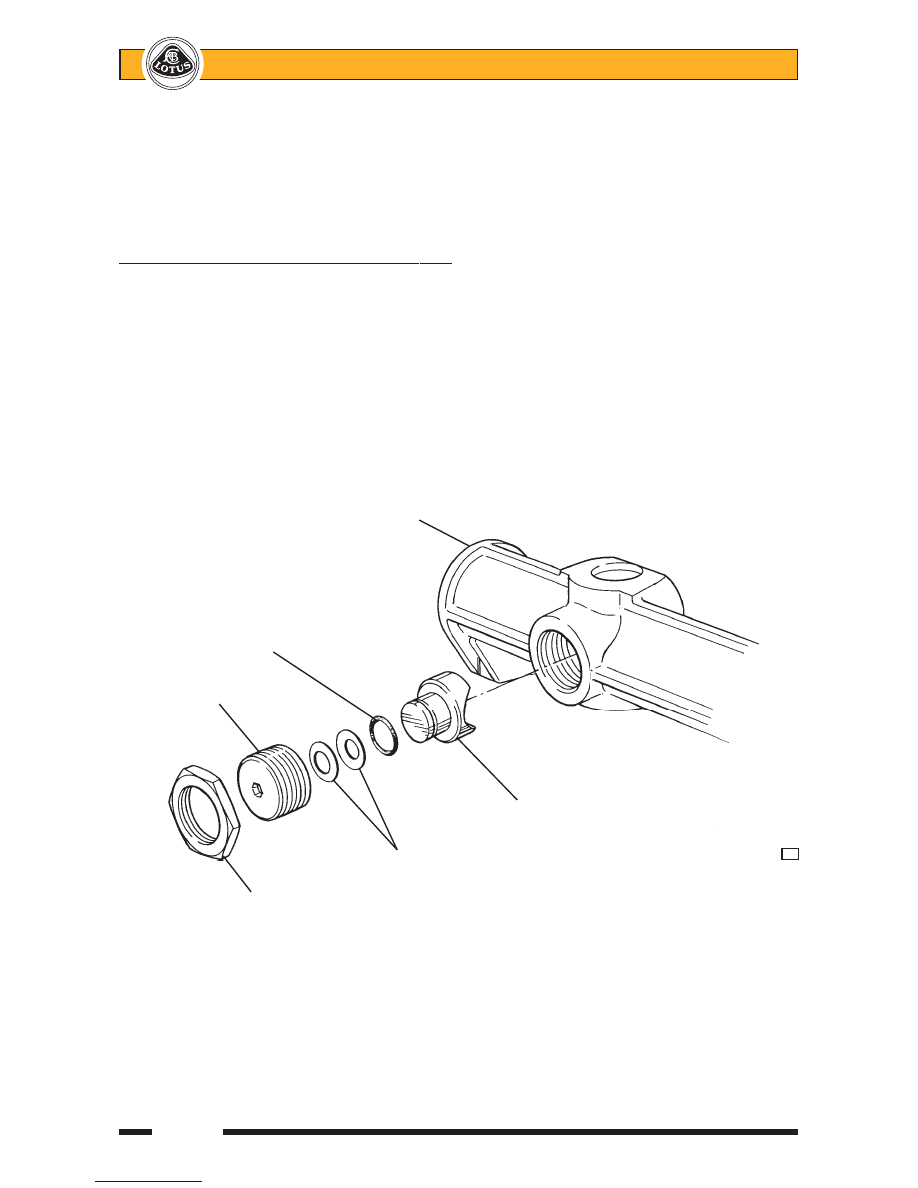

The following information applies to one-piece alloy bodied steering rack units:

A thrust pad backed by a pair of belleville washers, is used to control the preload between the rack bar

teeth and the pinion gear, and is adjustable via a threaded backstop plug. The correct preload allows the

horizontally mounted rack bar (column disconnected) to be pulled through its full travel by a steady force of 50

- 70 N (12 - 16 lbf). The rack and pinion assembly must be removed from the chassis before any adjustment

may be carried out.

To adjust the thrust pad, release the locknut (36mm socket) and use a 5.5mm hexagonal bit to adjust the

backstop as required before tightening the locknut. For an approximate initial setting, screw in the backstop

plug until solid, then back off ½ turn.

The following information applies to alloy/steel tube type steering rack units:

A thrust pad backed by a coil spring, is used to control the preload between the rack bar teeth and the

pinion gear, and is adjustable via a threaded backstop plug. The correct preload allows the horizontally mounted

rack bar (column disconnected) to be pulled through its full travel by a steady force of 50 - 100 N (12 - 20 lbf).

The rack and pinion assembly must be removed from the chassis before any adjustment may be carried out.

To adjust the thrust pad, release the locknut (36mm socket) and use a 19mm hexagonal bit to adjust the

backstop as required before tightening the locknut. For an approximate initial setting, screw in the backstop

plug until solid, then back off ¼ turn.

Rack housing

'O' ring

Threaded plug

Thrust pad

Belleville washers

h56

Locknut