Lotus Eleven/Elise/Exige. Instruction - part 63

Lotus Service Notes

Section JJ

Page 5

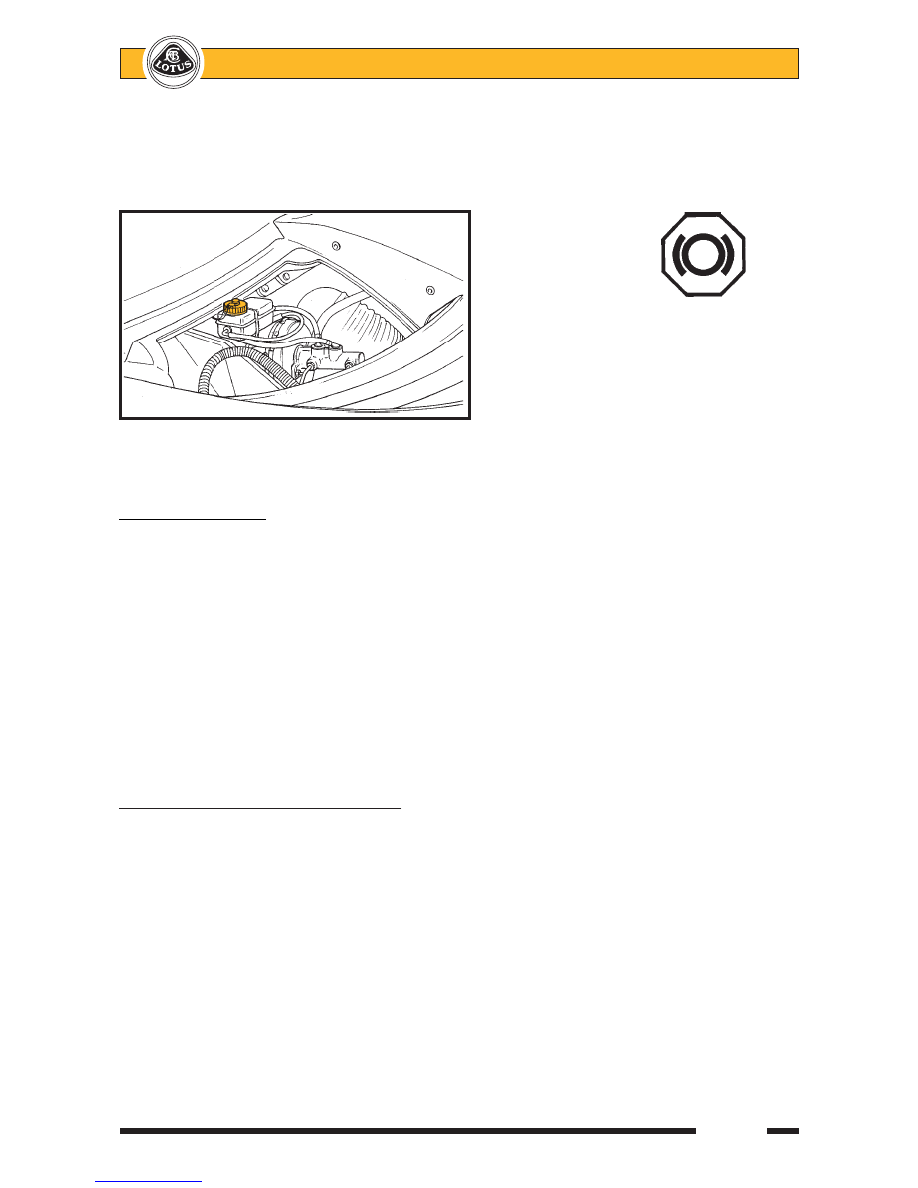

If the reservoir needs topping up, first clean around the cap to reduce the possibility of contamination

before unscrewing the cap; it is not necessary to disconnect the level sensor cables. Take suitable precautions

to guard against damage to paintwork caused by brake fluid dripping from the level sensor. Use only a fresh

supply of DOT 4 non-mineral type fluid, identified by a yellow and black symbol.

Do NOT use DOT 5 silicone fluid, or any

fluid which has been exposed to the atmos-

phere for more than a brief period, or any fluid

suspected of being wet, dirty or contaminated.

Do not overfill. Replace the filler cap securely.

Some service operations, such as replacing brake pads, will result in the displacement of fluid from the

hydraulic circuit back into the reservoir. In order to prevent fluid overflowing from the reservoir, it may be

necessary to remove some fluid using a syringe.

Renewal of Brake Fluid

Brake fluid absorbs water from the atmosphere over a period of time (hygroscopical), resulting in a

lowering of the boiling point of the fluid, and corrosion of the hydraulic system. For optimum safety and brake

performance, the brake fluid should be renewed every twelve months (including clutch release system).

Brake Bleeding Procedure

If the brake fluid is to be renewed, or an hydraulic component replaced, the system should be bled of air

using the following procedure:

1.

Using conventional instruction techniques, or low air pressure applied to the reservoir, bleed the system

from each calliper bleed nipple in turn until no air bubbles can be seen.

2.

Connect the Lotus Scan tool and select ABS and follow the brake bleeding instructions. Whilst this

automatic process is taking place (with all 4 calliper nipples open), gently cycle the brake pedal up and

down whilst keeping the reservoir topped up, to move any air bubbles displaced from the ABS unit down

the hydraulic lines. Finish by closing each nipple with the pedal down.

3.

Repeat step (1) to purge each calliper feed line in turn.

JJ.4 - FRONT BRAKE PAD REPLACEMENT

Pad thickness may be checked with the wheel removed without disturbing the calliper.

Standard pad thickness (excluding backplate);

9.0 mm

Minimum pad thickness (excluding backplate);

2.5 mm

If the thickness of any pad is below the specified minimum, the axle set of pads should be renewed. Note

that the pad backplates are factory fitted with anti-squeal overlays, and are identified with T 4139 on the

backplate.

For cars used on track, where sustained hard use and extreme brake temperatures are likely to occur,

'Motorsport' pads made by Pagid may be fitted in complete vehicle sets under part number A111J0150S (front)

and A111J0151S (rear).

1.

To remove the brake pads; Remove the 'R' clip from the lower of the two pad retaining pins, and withdraw

the lower of the pin taking care to restrain the anti-rattle spring. Remove the second retaining pin to-

gether with the anti-rattle spring plate. Withdraw the pads from the calliper. Measure the lining thickness

and renew the axle set of pads if any lining is below 2.5 mm.

j146

BRAKE FLUID

ohs139

RESERVOIR

CAP

Non-mineral type

brake fluid symbol

(Yellow & Black)