Carrier 30AWH004HB / 30AWH006HB / 30AWH008HB / 30AWH012HB. Service Manual - page 7

97

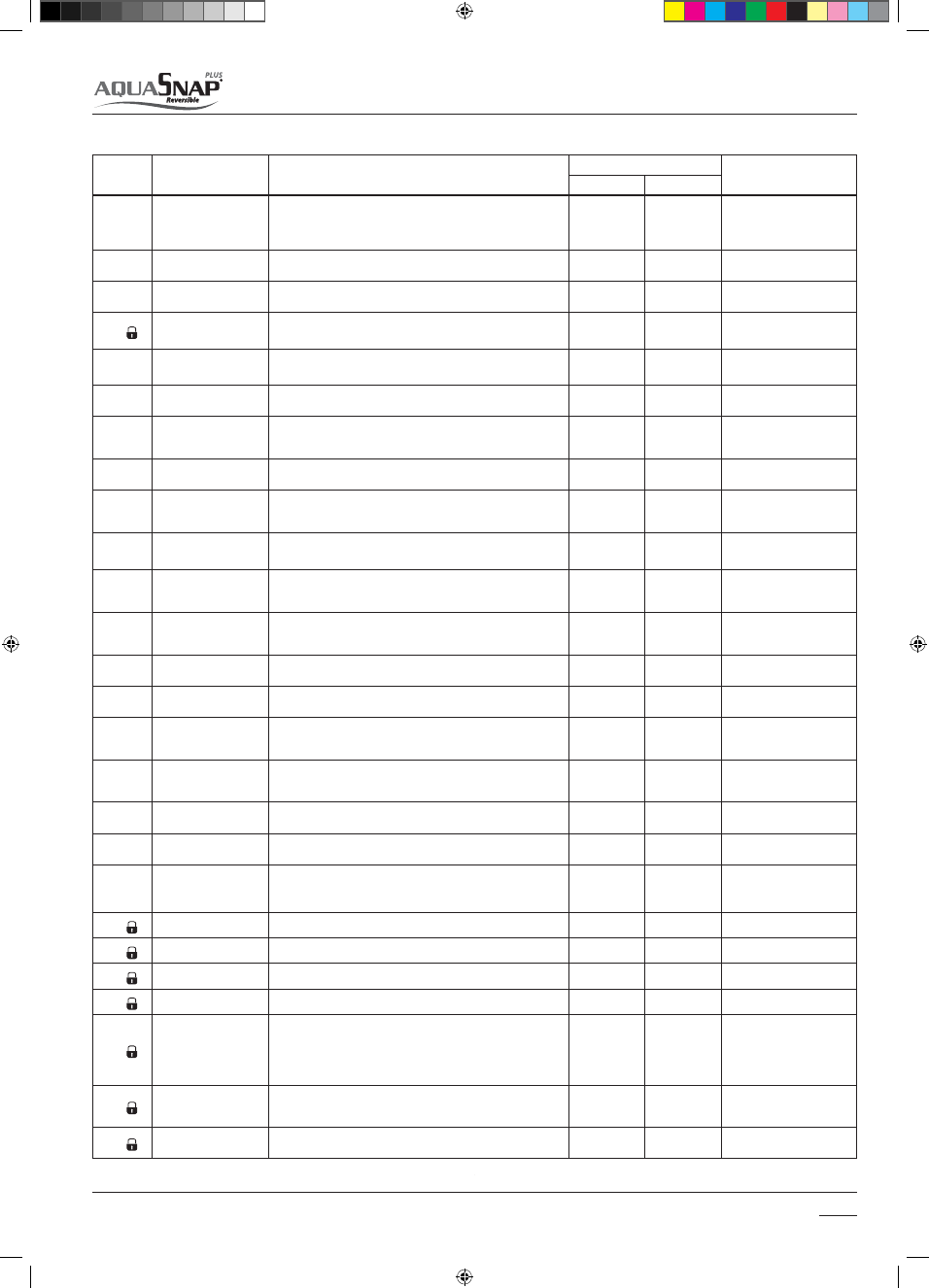

30AW

Carrier

interfaces

7

108

ALARM-DEFROST OR

HUMIDITY

SELECTION

This code is use to select the output connected at PIN 11 on

terminal strip:

1. Unit alarms and/or Defrost

2. Humidity Control

1

2

2

109

FROST DELTA

SET-POINT

This code is use to set the frost delta set-point used by the Anti

frost protection logic as per algorithm.

0°C

6°C

1°C

110

RESET COMPRESSOR

RUN-TIME

This code is use to reset the compressor timer to zero.

No

yes

No

111

(

)

FLOW SWITCH STATUS

This code displayes the Flow Switch status:

0. Water not flowing

1. Water flowing

-

-

-

112

HEAT CLIMATIC

CURVE NUMBER

This code is use to select the heat climatic curve number:

0. No predefined climatic curve (Installer has to draw CC)

1 - 12. Refers to NUI manuals for climatic curve details.

0

12

0

113

HEAT WATER

SET-POINT

This code is use to set the fixed heating water set-point.

20°C

60°C

45°C

114

ECO HEAT

TEMPERATURE

REDUCTION

This code is use to set the temperature reduction value for fixed

heating water set-point when the unit is in ECO mode.

1°C

20°C

5°C

115

COOL WATER

SET-POINT

This code is use to set the fixed cooling water set-point.

4°C

25°C

7°C

116

ECO COOL

TEMPERATURE

REDUCTION

This code is use to set the temperature reduction value for fixed

cooling water set-point when the unit is in ECO mode.

1°C

10°C

5°C

117

COOL CLIMATIC

NUMBER

This code is use to select the cool climatic curve number:

0. No predefined climatic curve (Installer has to draw CC)

1 - 2. Refers to NUI manuals for climatic curve details

0

2

0

118

MIN OUTDOOR

AIR TEMPERATURE

HEATING

This code is use to select the minimum outdoor temperature of

the heating climatic curve, depending on the country where the

system is installed.

-20°C

+10°C

-7°C

119

MAX OUTDOOR

AIR TEMPERATURE

HEATING

This code is use to select the maximum outdoor temperature of

the heating climatic curve.

10°C

30°C

20°C

120

MIN WATER TEMPERA-

TURE HEATING

This code is use to select the minimum water temperature of the

heating climatic curve.

20°C

60°C

40°C

121

MAX WATER TEMPERA-

TURE HEATING

This code is use to select the maximum water temperature of the

heating climatic curve.

20°C

60°C

55°C

122

MAX OUTDOOR

AIR TEMPERATURE

COOLING

This code is use to select the maximum outdoor temperature of

the cooling climatic curve, depending on the country where the

system is installed.

24°C

46°c

40°C

123

MIN OUTDOOR AIR

TEMPERATURE CO-

OLING

This code is use to select the minimum outdoor temperature of

the cooling climatic curve

0°C

30°C

22°C

124

MIN WATER TEMPERA-

TURE COOLING

This code is use to select the minimum water temperature of the

cooling climatic curve.

4°C

20°C

4°C

125

MAX WATER TEMPERA-

TURE COOLING

This code is use to select the maximum water temperature of the

cooling climatic curve.

4°C

20°C

12°C

126

GMC OAT THERMISTOR

This code is use to define if GMC OAT thermistor is installed or n

ot:

1. GMC thermistor installed

2. GMC thermistor not installed

1

2

2

127

(

)

TO SENSOR VALUE

This code displayes the outdoor air temperature value read by

the TO sensor.

-

-

-

128

(

)

TE SENSOR VALUE

This code displayes the refrigerant temperature value read by the

TE sensor.

-

-

-

129

(

)

TS SENSOR VALUE

This code displayes the suction temperature value read by the

TS sensor.

-

-

-

130

(

)

TD SENSOR VALUE

This code displayes the discharge temperature value read by the

TD sensor.

-

-

-

131

(

)

CDU MODE

This code displayes the actual Heat Pump operating mode:

0ò

2. Cool

3. Heat

4. Fail

5. Defrost

-

-

-

132

(

)

MAX COMPRESSOR

FREQUENCY

This code displayes the maximum compressor frequency calcula-

ted by GMC control board.

-

-

-

133

(

)

REQUESTED

FREQUENCY

This code displays the requested frequency by the system

control.

-

-

-

Code Nr.

Name

DESCRIPTION

VALUE RANGE

STANDARD

Min

Max

14-03-2011 14:46:20