DDFP SERIES ENGINES FOR FIRE PUMP APPLICATIONS MP-4. Manual - part 10

DDFP

SECTION 3.5

Page 32

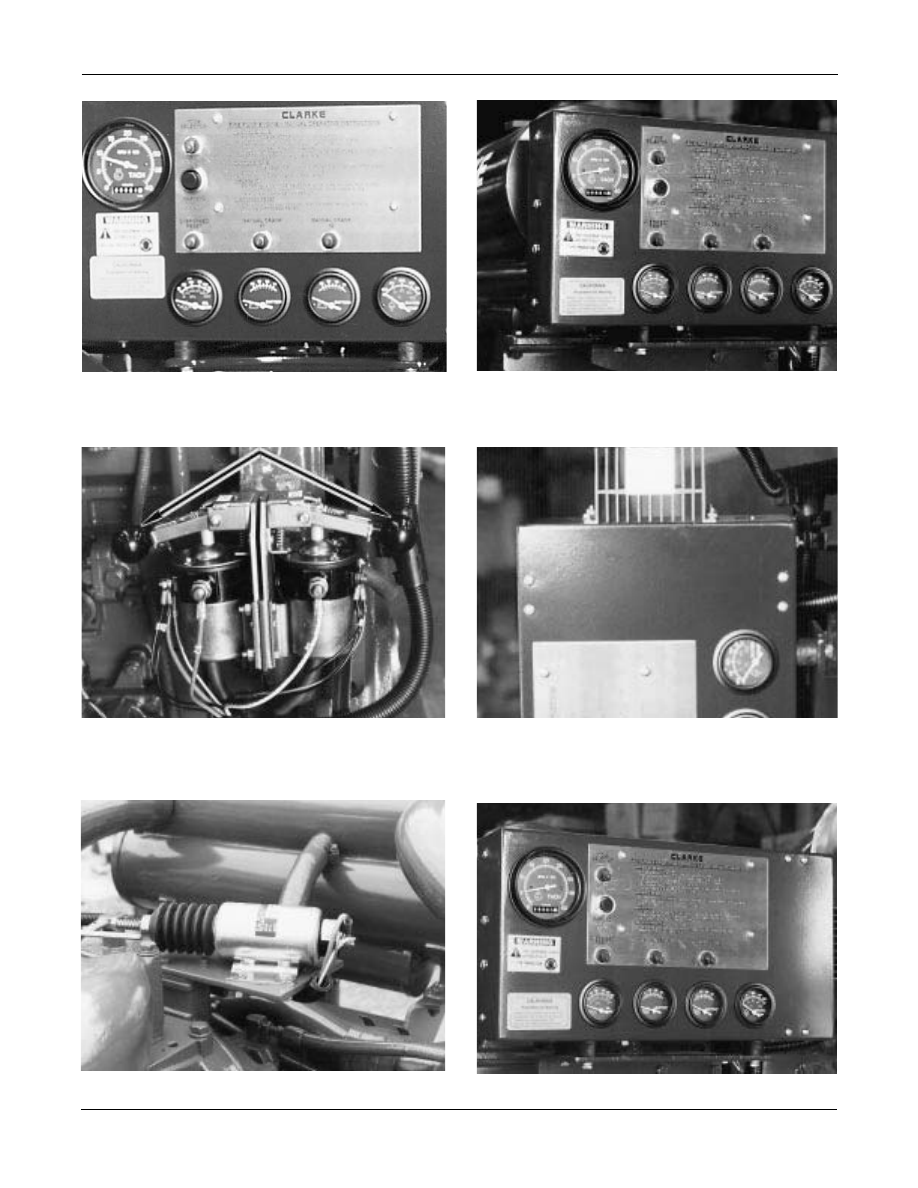

Fig. 2 - Emergency Operating Instructions

Fig. 3 - Automatic - Manual Mode Selector

Fig. 7 - Instrument Panel

Fig. 4 - Manual Contactors

Fig. 5 - DC Junction Box

Fig. 6 - Governor Solenoid

➞

➞

➞

➞

➞

➞