Yanmar marine engine 6LPA-STP2, 6LPA-STZP2. Manual - part 3

PRODUCT OVERVIEW

6LPA Series Operation Manual

11

12/05

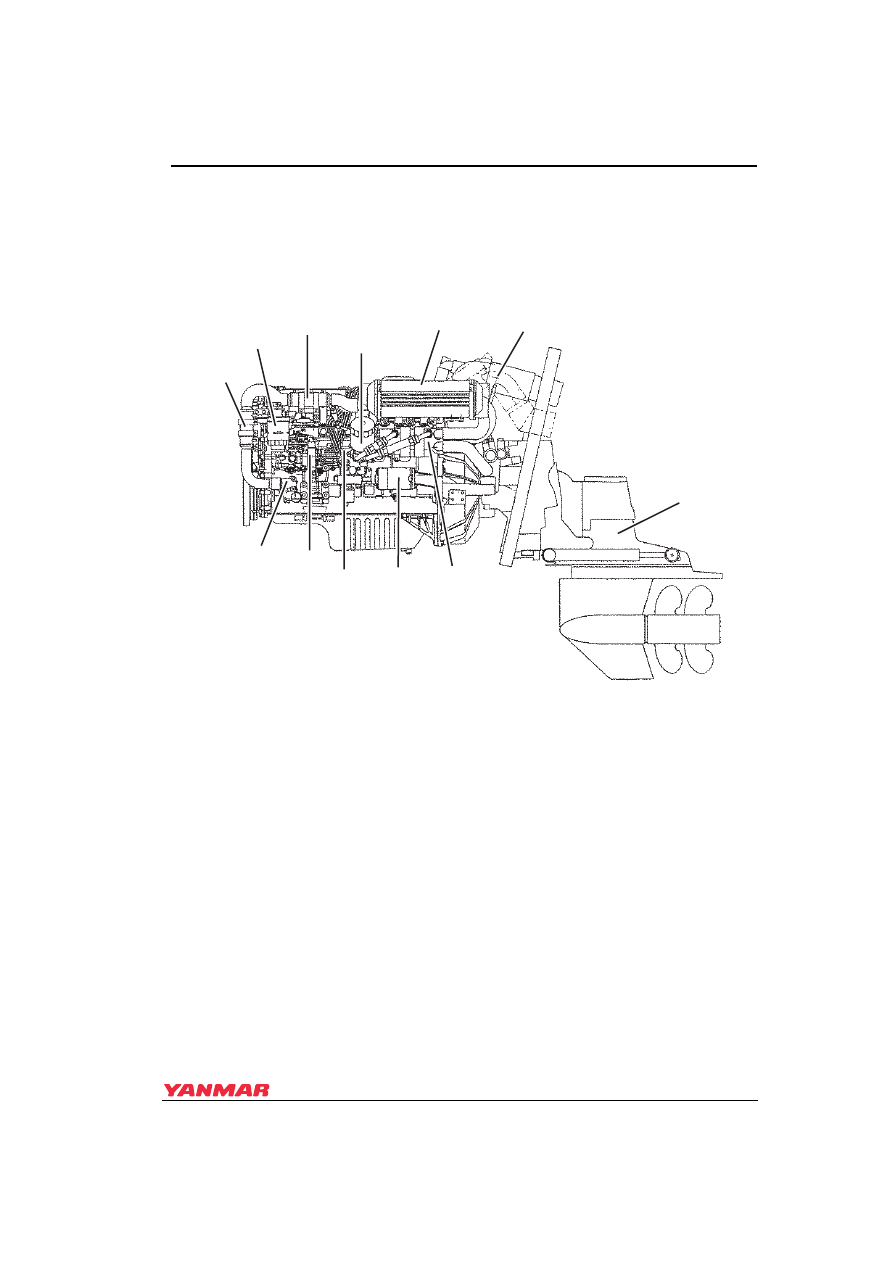

COMPONENT IDENTIFICATION

Service Side (Left Side as Viewed from Propeller)

Note: 6LPA-STZP2 with stern drive shown. Components marked with an * are for

6LPA-STZP2 only.

Figure 1

Figure 1

1 – Fuel Cooler

2 – Fuel Filter

3 – Power Steering Oil Cooler*

4 – Engine Oil Filter

5 – Intercooler

6 – Mixing Elbow

7 – Engine Oil Cooler

8 – Starter

9 – Engine Oil Cooler

10 – Fuel Injection Pump

11 – Seawater Pump

12 – Stern Drive

(1)

(2)

(3)

(4)

(5)

(6)

(12)

(11)

(10)

(9)

(8)

(7)

0004884