Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 721

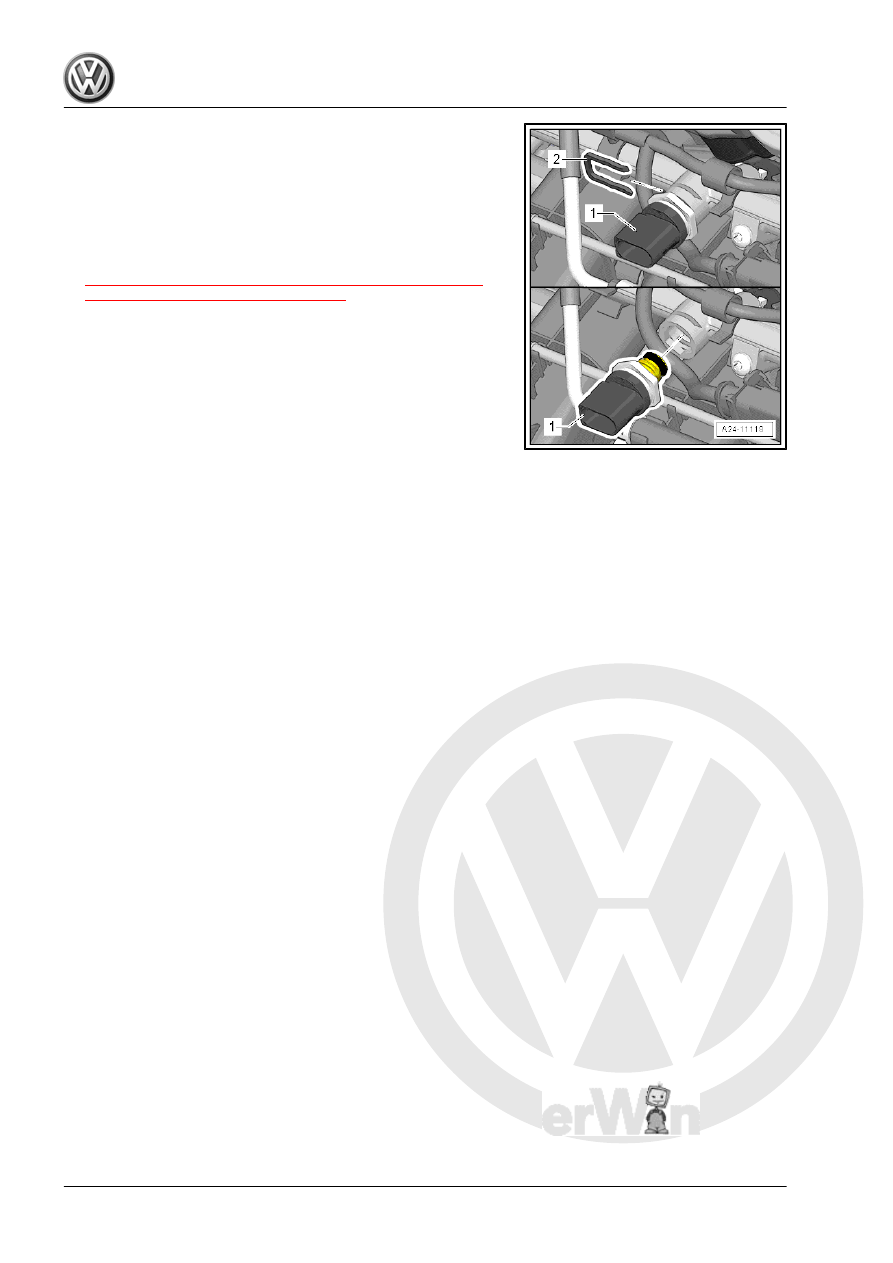

– Carefully slide the Low Fuel Pressure Sensor - G410- -1- all

the way into the fuel rail.

– To secure the Low Fuel Pressure Sensor - G410- , slide the

clip -2- into the groove.

– Connect the connector.

Tightening Specifications

♦ Refer to

⇒ “4.2.2 Overview - Intake Manifold Lower Section with Fuel

Rail, Multiport Fuel Injection”, page 302

.