Content .. 1898 1899 1900 1901 ..

Volkswagen New Beetle. Manual - part 1900

Test Requirements

Ensure battery is okay. Ensure all fuses are okay, battery voltage is at least 11.5 volts and fuel pump relay is

okay. Ensure all electrical accessories are off and A/C is off.

Test Procedure

1. Turn ignition off. Disconnect knock sensor No. 1 and 2 harness connectors, located at back of coolant

reservoir. See Fig. 67 . Check resistance between contacts No. 1 and 2, No. 1 and 3 and also No. 2 and 3

at each knock sensor, resistance should be infinite (no continuity). If no continuity is present in resistance

readings, go to next step. If continuity is present in any resistance reading, replace faulty knock sensor(s).

Erase DTC memory. Verify repair. Test is complete. Perform ECM relearn procedure. See TEST DRIVE

RELEARN PROCEDURE .

2. Turn ignition off. Loosen and retighten knock sensors No. 1 and 2 to 15 ft. lbs.(20 Nm). Erase DTC

memory. Perform ECM relearn procedure. See TEST DRIVE RELEARN PROCEDURE . If DTC(s)

do not reset, test is complete. If DTC(s) resets, go to next step.

3. Turn ignition off. Disconnect ECM harness connector, leave ECM disconnected from test box. Connect

Test Box (VAG 1598/31) to ECM harness connector. See CONNECTING VAG TEST BOX . Using

DVOM, check resistance between the following knock sensor harness connectors and VAG test box

sockets. See KNOCK SENSOR HARNESS CONNECTOR/TEST BOX SOCKET

IDENTIFICATION table. See Fig. 67 . Resistance should be a maximum of 1.5 ohms for each reading.

Check wiring for short circuit to one another in Knock sensor No. 1 (G61) harness connector. Check

wiring for short circuit to one another in Knock sensor No. 2 (G66) harness connector. If wiring is okay,

go to next step. If wiring is not okay, repair as necessary. After repairs, erase DTC memory. Verify repair.

Test is complete. Perform ECM relearn procedure. See TEST DRIVE RELEARN PROCEDURE .

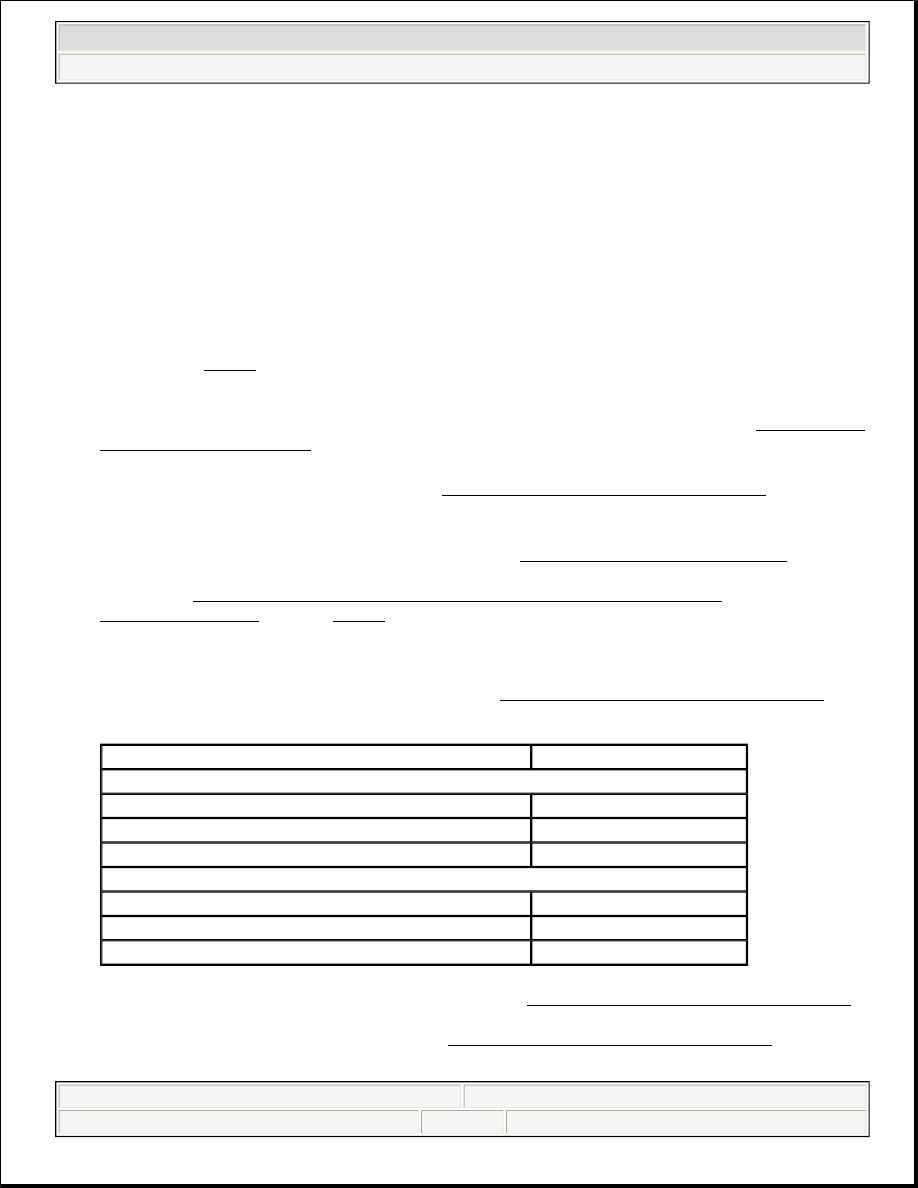

KNOCK SENSOR HARNESS CONNECTOR/TEST BOX SOCKET IDENTIFICATION

4. Erase DTC memory. Perform ECM relearn procedure. See TEST DRIVE RELEARN PROCEDURE .

If DTC(s) reset, replace faulty knock sensor(s). After repairs, erase DTC memory. Verify repair. Test is

complete. Perform ECM relearn procedure. See TEST DRIVE RELEARN PROCEDURE .

to ensure knock sensors perform properly. Contact surfaces between knock

sensor and cylinder block must be free of corrosion, dirt and grease.

Knock Sensor Harness Connector Terminal

VAG Test Box Socket

Knock Sensor No. 1 (G61 - Cylinders 1 & 2)

1 (Signal)

106

2 (Ground)

99

3 (Wire Shielding)

108

Knock Sensor No. 2 (G66 - Cylinders 3 & 4)

1 (Signal)

107

2 (Ground)

99

3 (Wire Shielding)

108

2003 Volkswagen New Beetle GLS

2002-2003 ENGINE PERFORMANCE Self-Diagnostics - 1.8L Turbo

Helpmelearn Repair Manuals

Wednesday, December 14, 2005 8:44:50 AM

Page 222

© 2004 Mitchell Repair Information Company, LLC.