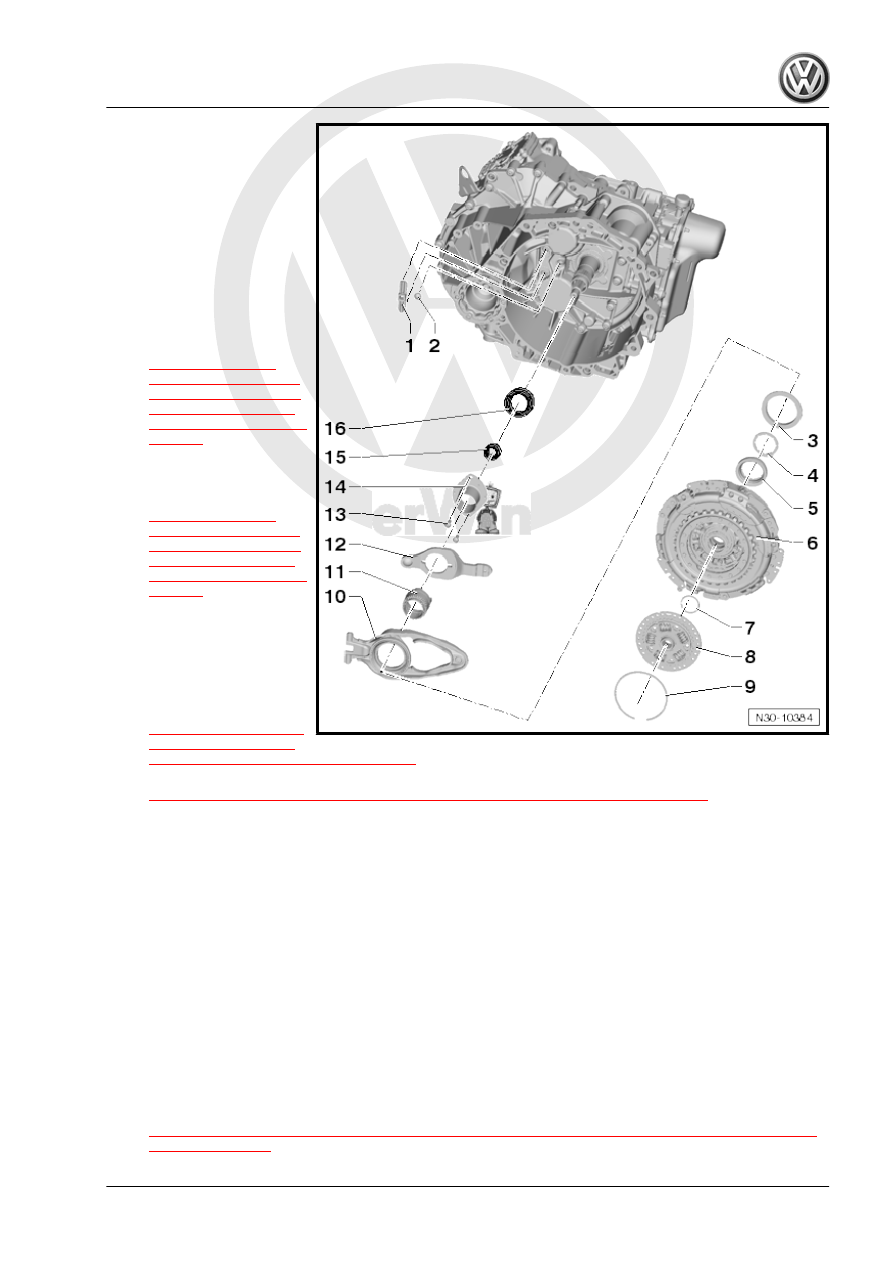

Volkswagen Golf Variant / Jetta. Manual - part 555

❑ For the large engaging

lever “K 1”

❑ Is not replaced

2 - Ball Stud

❑ For the small engaging

lever “K 2”

❑ Always replace when

replacing the dual clutch

3 - Shim “SK 1”

❑ Selecting thickness. Re‐

fer to

.

4 - Shim “SK 2”

❑ Selecting thickness. Re‐

fer to

.

5 - Small Engaging Bearing for

“K 2”

❑ Always replace when

replacing the dual clutch

6 - Dual Clutch

❑ Removing. Refer to

Production Date from 06/2011”, page 42

.

❑ Installing. Refer to

⇒ “2.4 Dual Clutch, Installing, Transmission Production Date from 06/2011”, page 58

.

7 - Circlip

❑ Always replace after removing

8 - Hub

9 - Circlip

❑ Always replace after removing

10 - Large Engaging Lever for “K 1”

❑ With engaging bearing

❑ Always replace when replacing the dual clutch

11 - Guide Sleeve Upper Section

❑ For the small engaging lever “K 2”

❑ Removed and installed together with the guide sleeve lower section

12 - Small Engaging Lever for “K 2”

❑ Is removed and installed together with the guide sleeve upper section and lower section

❑ Refer to

⇒ “2.3 K 1 and K 2 Clutch Engaging Bearing Position, Adjusting, Transmission Production Date from

2. Dual Clutch, Removing and Installing, from Transmission Production Date 06/2011

41